Fire hose connector

A fire hose and joint technology, applied in fire rescue and other directions, can solve problems such as water waste, increase interface pressure, loosening, etc., to avoid water waste, increase tightness, and improve practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

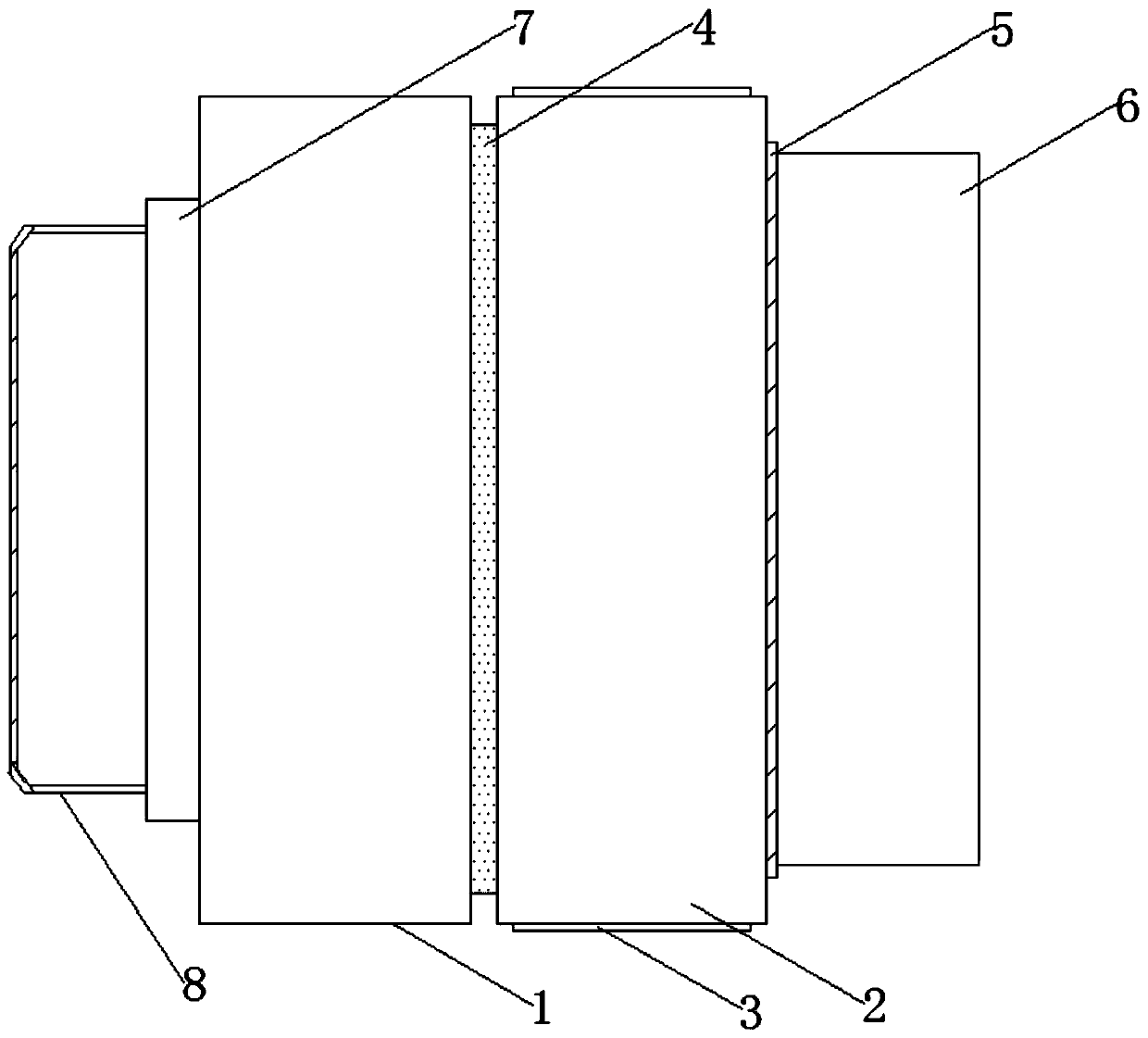

[0024] Refer to Figure 1-4 ,

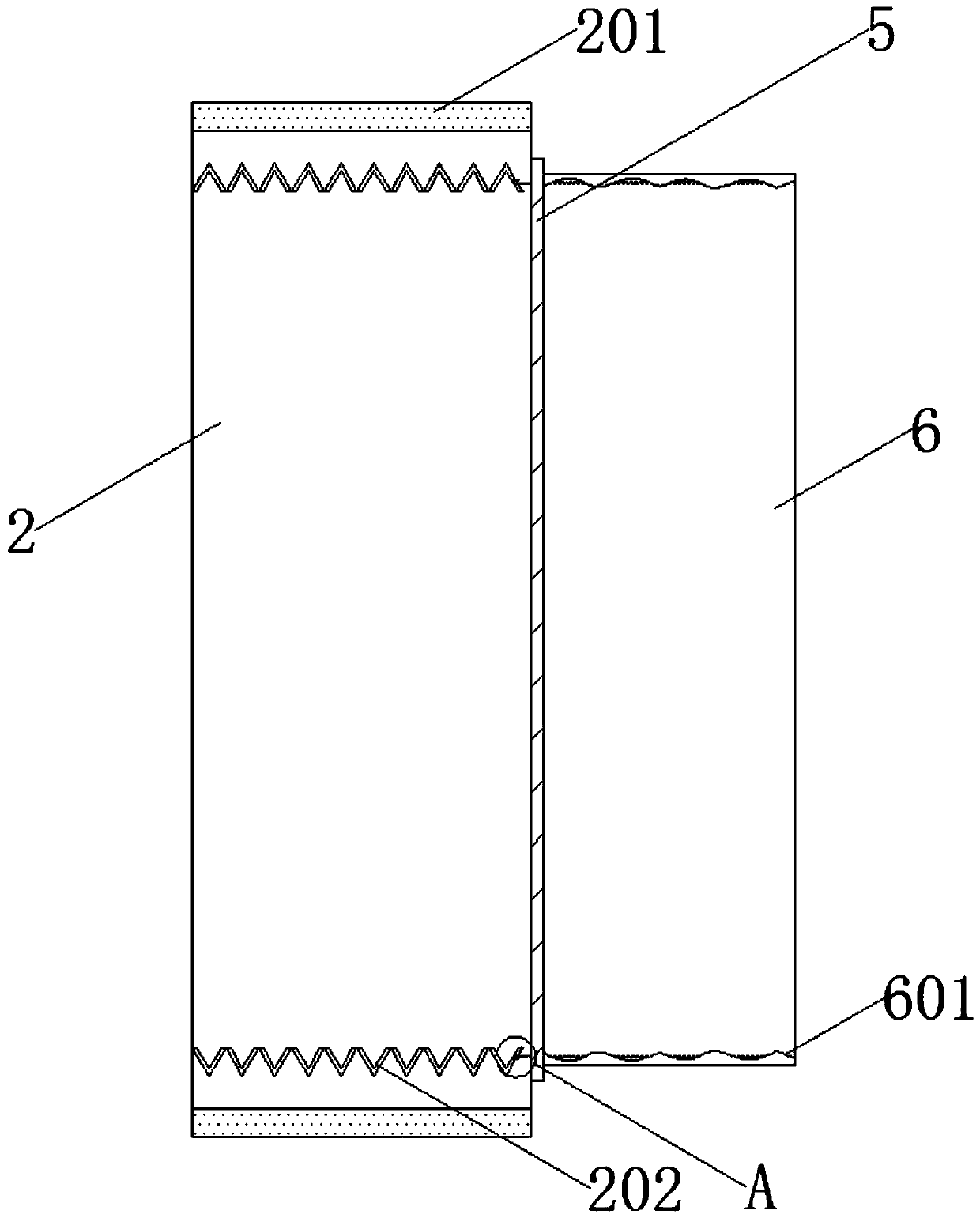

[0025] The fire hose joint provided by this embodiment includes a joint shaft 1, a connecting housing 2 and a partition 3. The connecting housing 2 is located on one side of the joint shaft 1, and the partitions 3 are respectively located on the side of the connecting housing 2. On one side, one side of the connecting housing 2 is provided with a connecting groove 4, and the connecting housing 2 is connected to the joint shaft 1 through the connecting groove 4, and one side of the connecting housing 2 is fixedly connected with a connecting plate 5. An interface 6 is fixedly connected to one side, a reinforcing plate 7 is fixedly connected to one side of the joint shaft body 1, and a rotating disk 8 is fixedly connected to one end of the reinforcing plate 7.

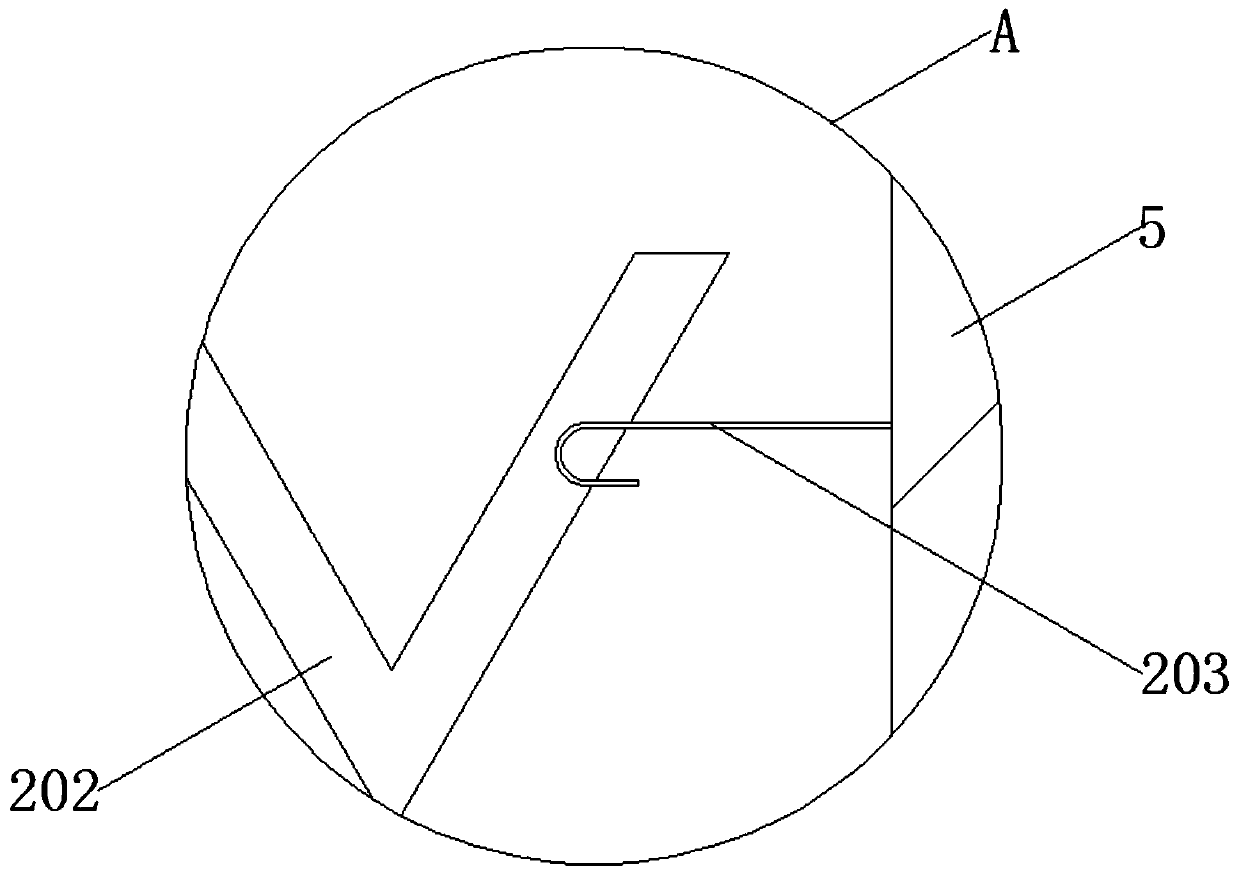

[0026] Further, the inner edge of the connecting shell 2 is provided with a limiting strip 201, and one side of the limiting strip 201 protrudes 1.2 cm from the inner edge of the connecting she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com