External desulfurization circulating spraying system

A cyclic spraying, external technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of increasing gas-liquid full contact, scouring of spray layer support beams, wasting energy and energy consumption, etc. Enhance the effect of stable performance, good locking, and good limit use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

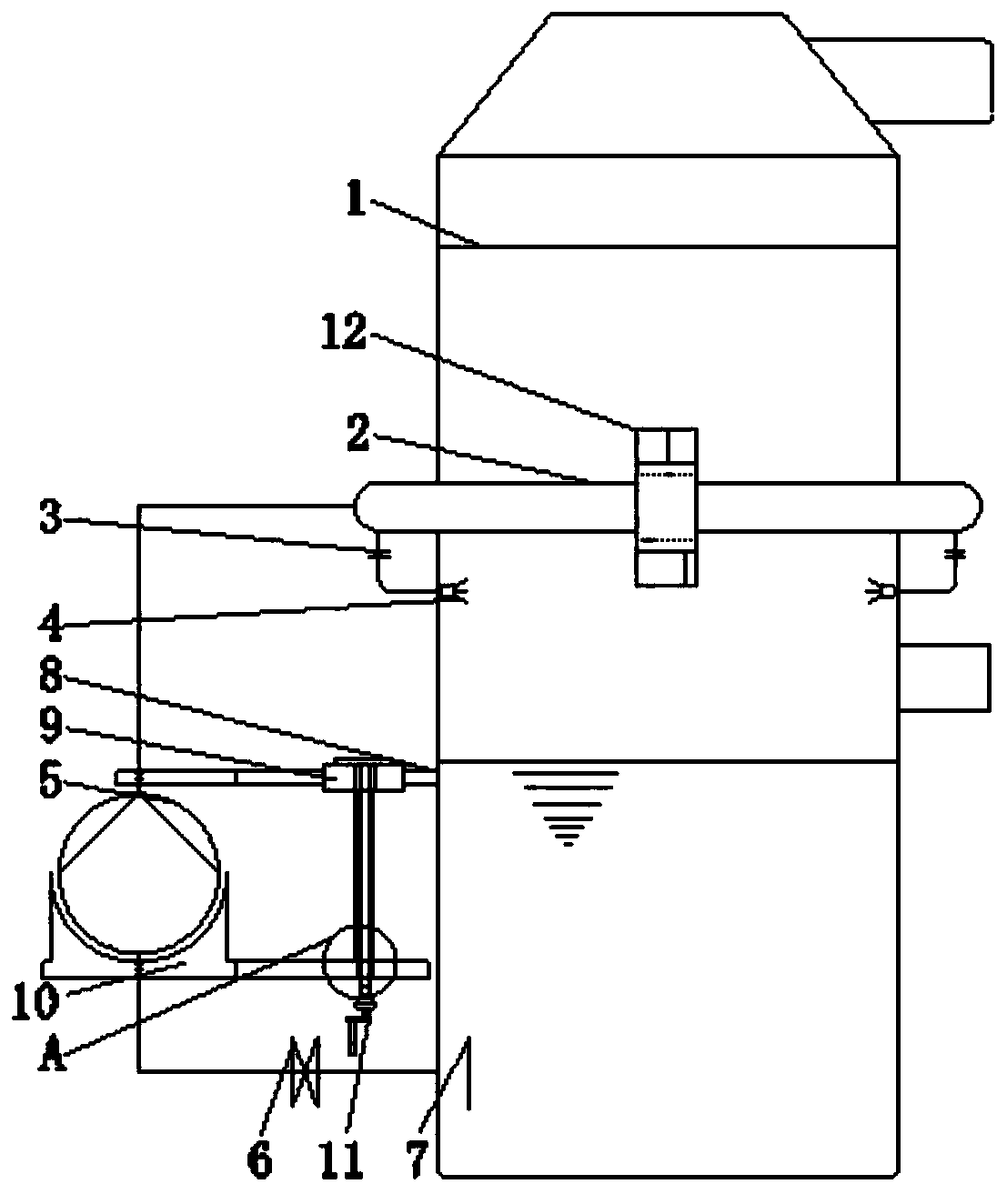

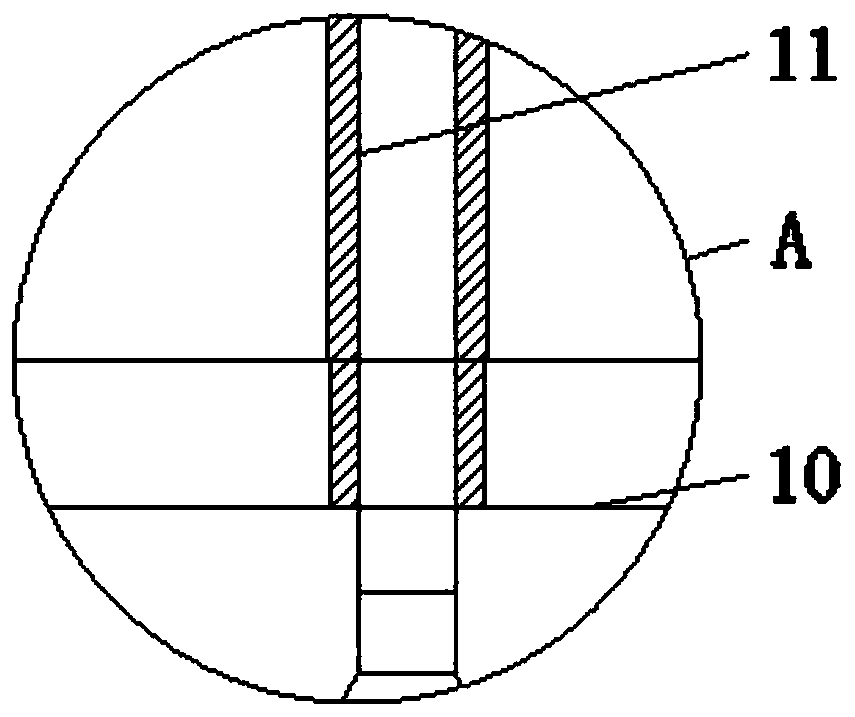

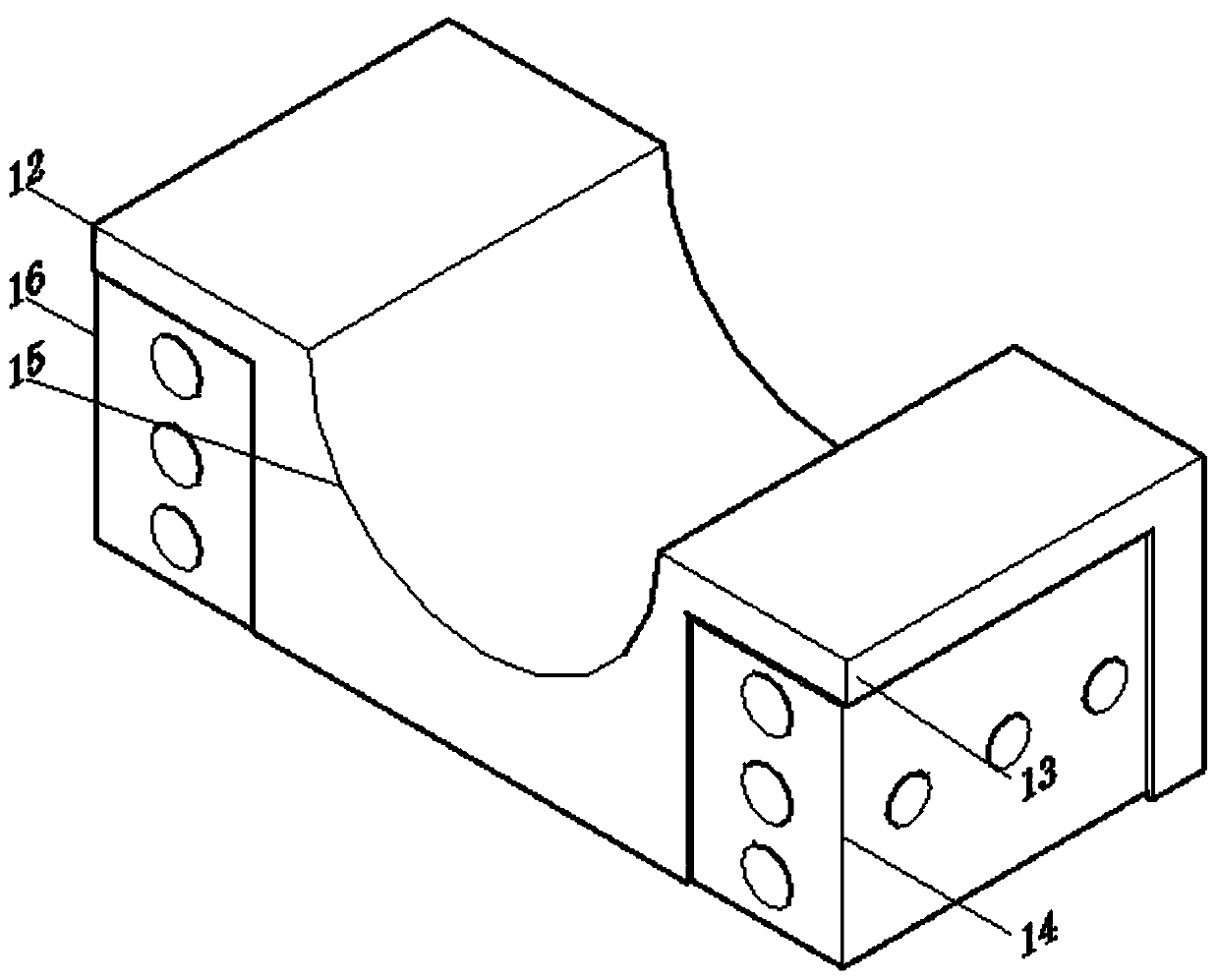

[0025] Its structure is mainly to arrange the slurry circulation main pipe outside the tower, the spray main pipe is arranged circumferentially, and the branch pipes are evenly distributed at the lower part of the main pipe according to the angle, and the nozzle 4 is arranged at the end of the branch pipe, and the nozzle 4 is inserted into the absorption tower. The spray main pipe can be rubber-lined pipe or glass fiber reinforced plastic pipe, the spray branch pipe is made of glass fiber reinforced plastic pipe, the nozzle 4 adopts the spiral cone atomizing nozzle 4 with a spray angle of 120 degrees, and the atomized droplets of the conical structure sprayed by the nozzle 4, in order to ensure All the flue gas passes through the layer of atomized droplets, and the atomized droplets must cover the entire section of the absorption tower;

[0026] After adopting the desulfurization technology of the external desulfurization circulation spray system, the nozzles 4 are all arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com