Vertical scraper central unloading and filtering centrifugal machine

A technology of central unloading and centrifuge, which is applied in the direction of centrifuge, etc., can solve the problems of long transformation period, high modification cost, and unable to change the backward situation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

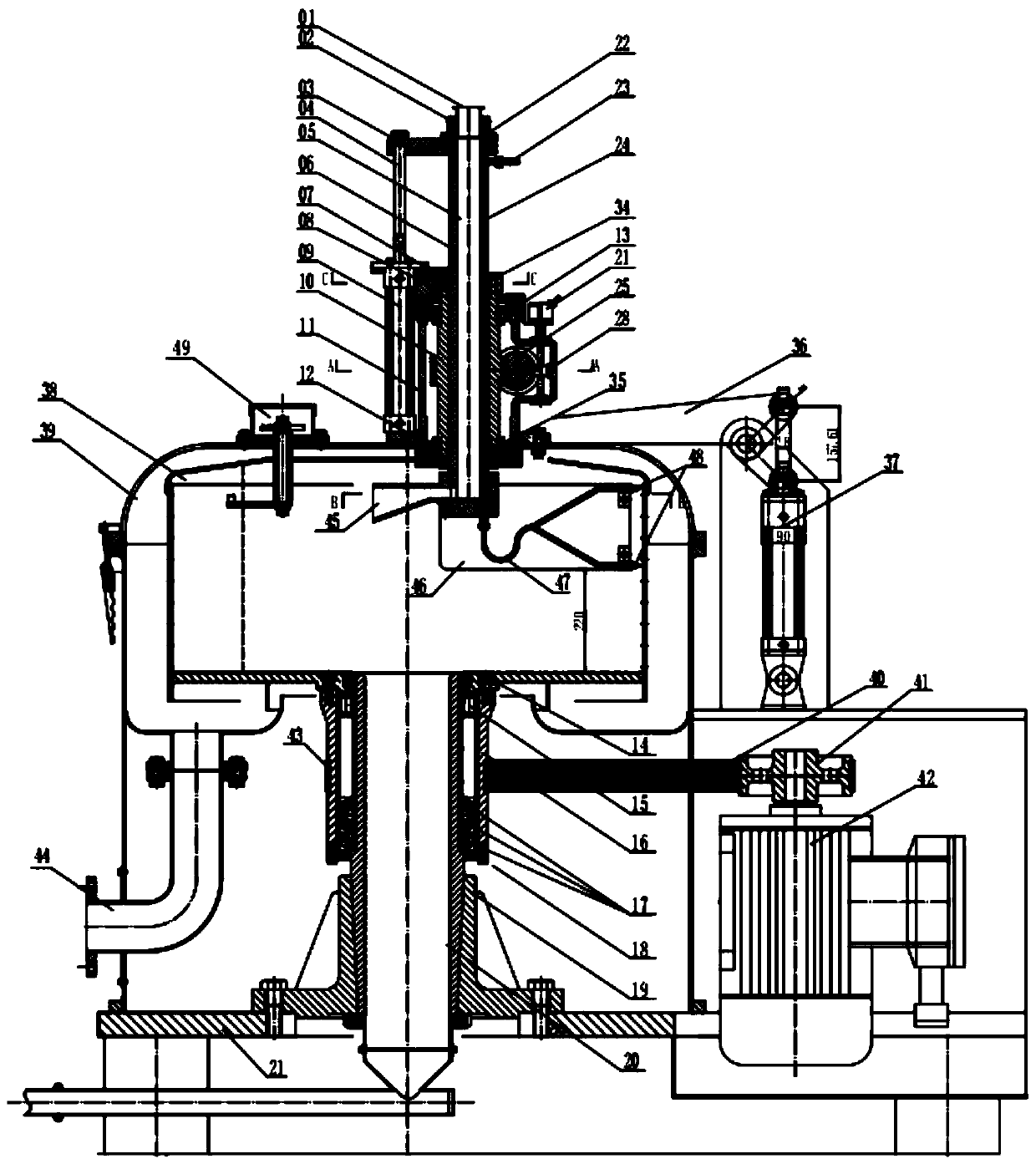

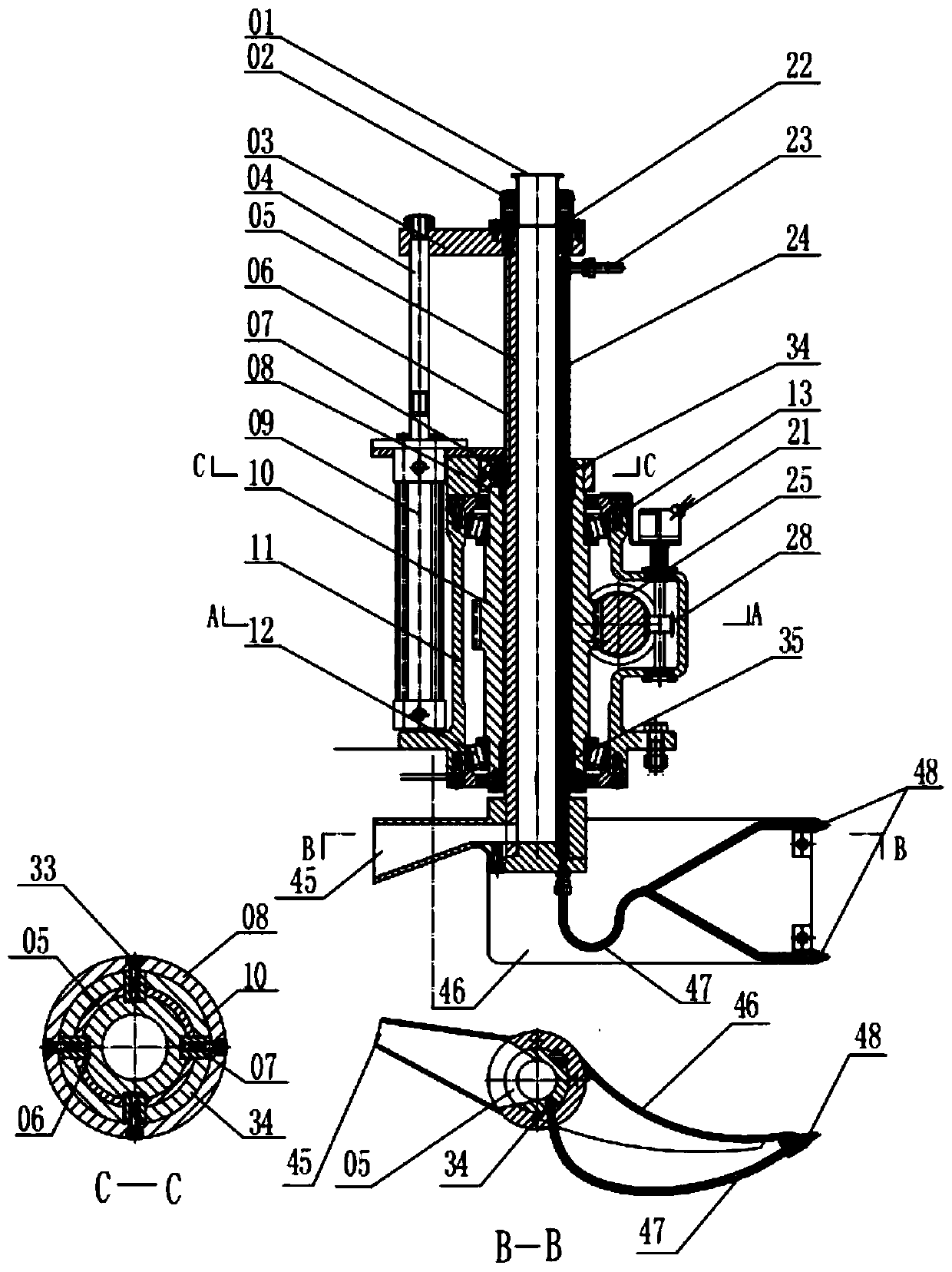

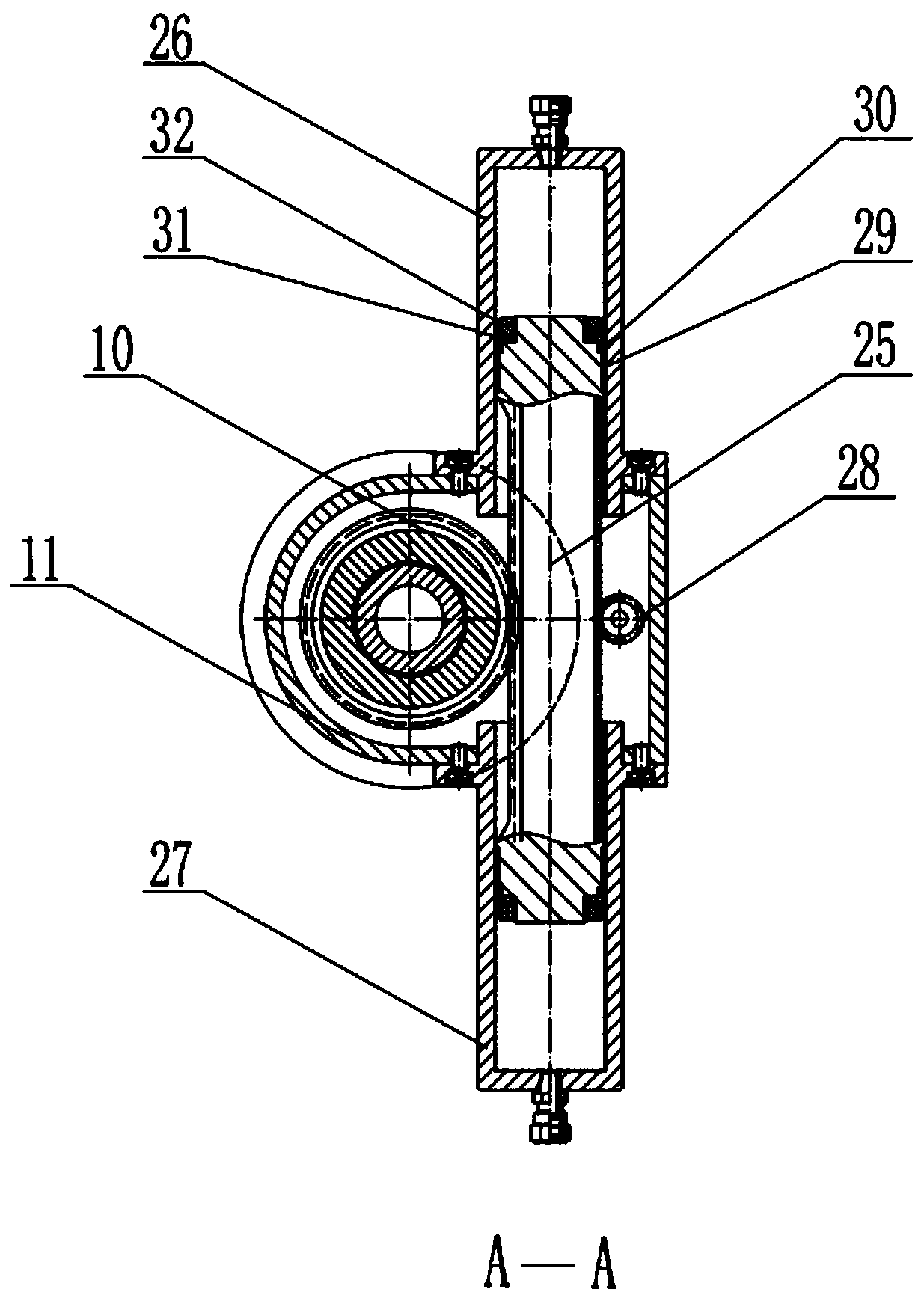

[0040] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 11 :

[0041] A vertical scraper center discharge filter centrifuge, including a fixed shaft 20 fixed by the main shaft, the shaft hole of the fixed shaft 20 is a discharge channel, the fixed shaft 20 is connected to the flange seat 19 and installed on the base plate 21. The bearing outer drum 16 is installed on the fixed shaft 20 through the bearings 15 and 17. The bearing outer drum 16 is connected to the rotating drum 38 and fastened with the inner hexagon screw 14. There is a belt groove 43 on the bearing outer drum 16, and the motor 42 passes through the pulley. 41. The transmission belt 40 drives the bearing outer drum 16 and the rotating drum 38 to rotate, and the scraper bar 05 moves up and down and rotates. Air knife integrated structure sees B-B view), pusher plate 46, air pipe 47, cloth opening 35 and other functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com