Auxiliary equipment for drilling holes in the motor housing

A technology for motor casings and auxiliary equipment, which is applied in drilling/drilling equipment, metal processing equipment, boring/drilling, etc., and can solve problems such as inconsistent installation hole positions and low drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

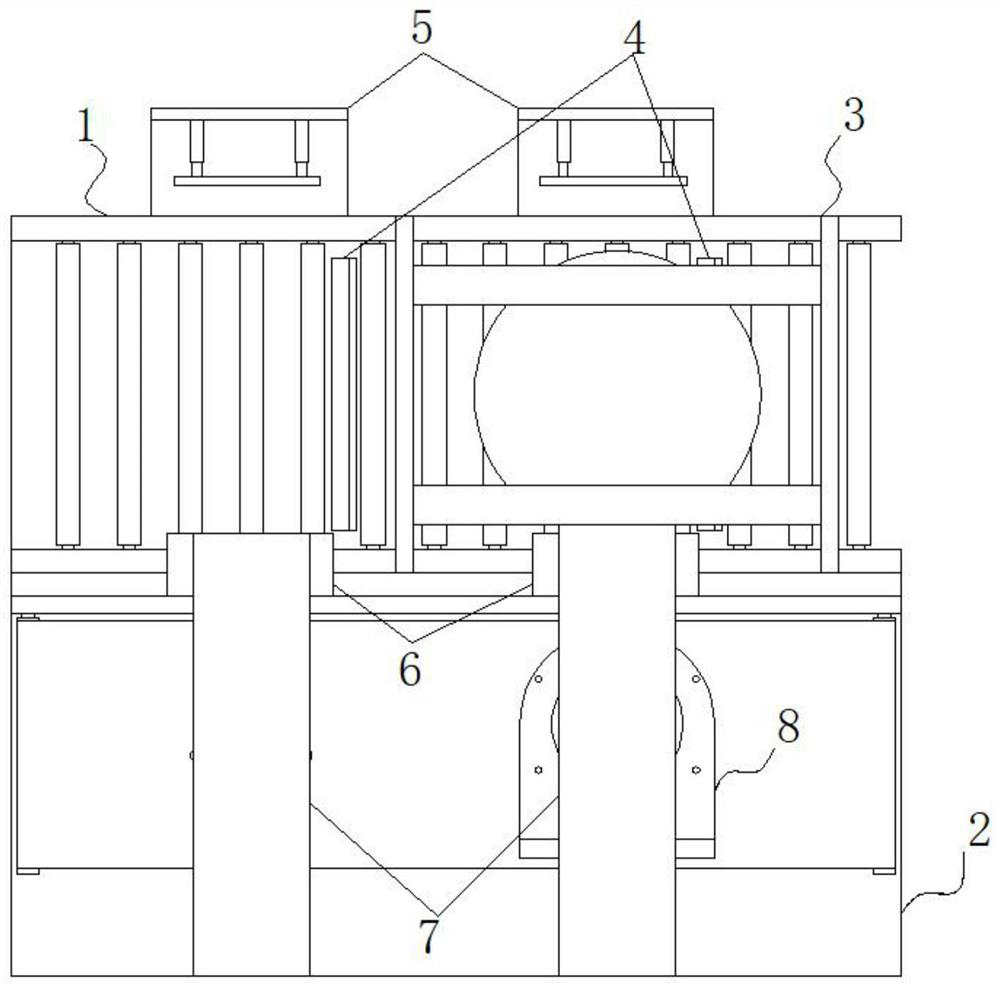

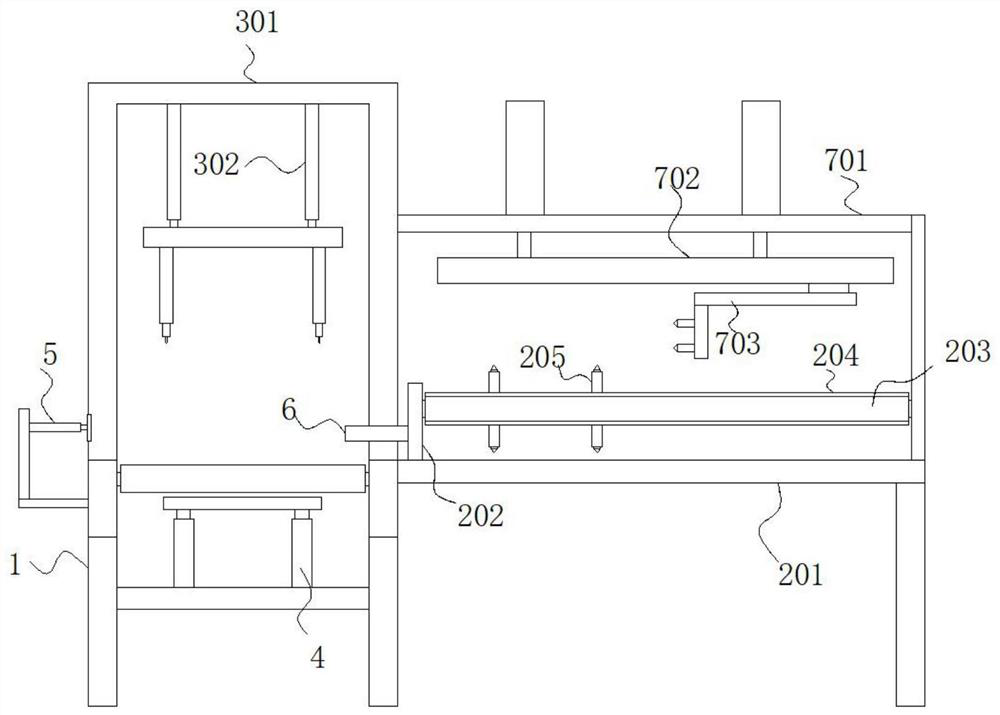

[0045] The conveying assembly 1 includes a bottom bracket, and the bottom bracket is fixedly connected to the support frame 201. Two groups of side baffles arranged in parallel are installed on both sides of the top of the bottom bracket, and there are movable sockets along the side baffles between the two groups of side baffles. The rollers are equidistantly arranged in the length direction, and the rollers are driven and connected by means of sprockets and chains;

Embodiment 2

[0047] The blocking assembly 4 includes a crossbeam affixed to the bottom bracket, a fourth driving mechanism is affixed to the top of the crossbeam, and an L-shaped blocking plate arranged parallel to the drum is affixed to the output end of the top of the fourth driving mechanism;

Embodiment 3

[0049] The push assembly 5 includes a side extension plate of an L-shaped structure fixed to the side baffle, and the side extension plate is located on the side of the bottom bracket away from the support frame 201, and the side extension plate is fixed on the side close to the support frame 201 There is a fifth driving mechanism arranged along the horizontal direction, and the output end of the fifth driving mechanism is fixedly connected with the active plate;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com