Cylindrical reinforcement cage production method and production system

A production system and production method technology, applied in the direction of auxiliary equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low production efficiency, difficulty in assembly site installation, and complicated steel cage structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

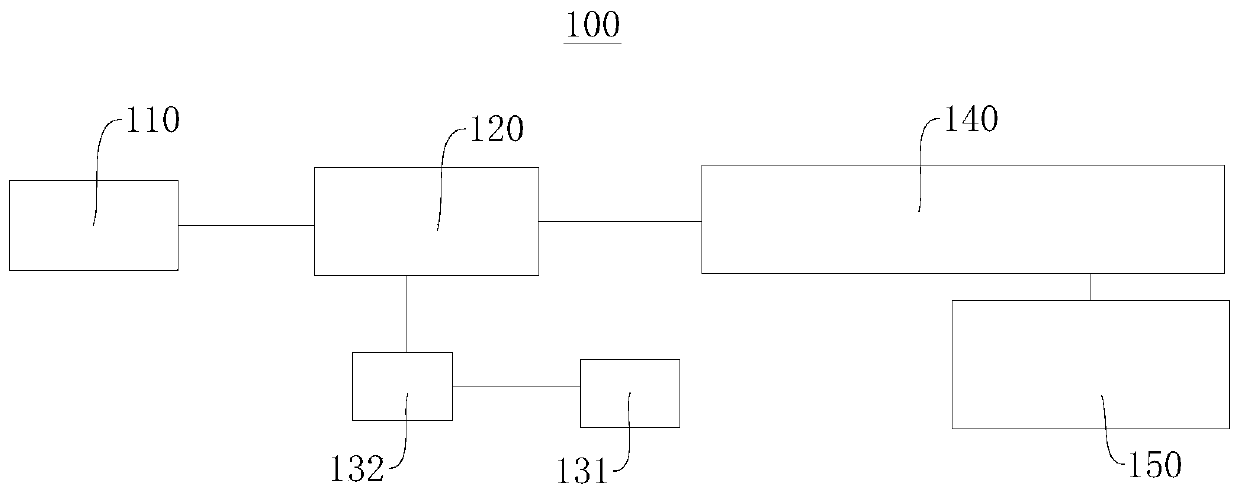

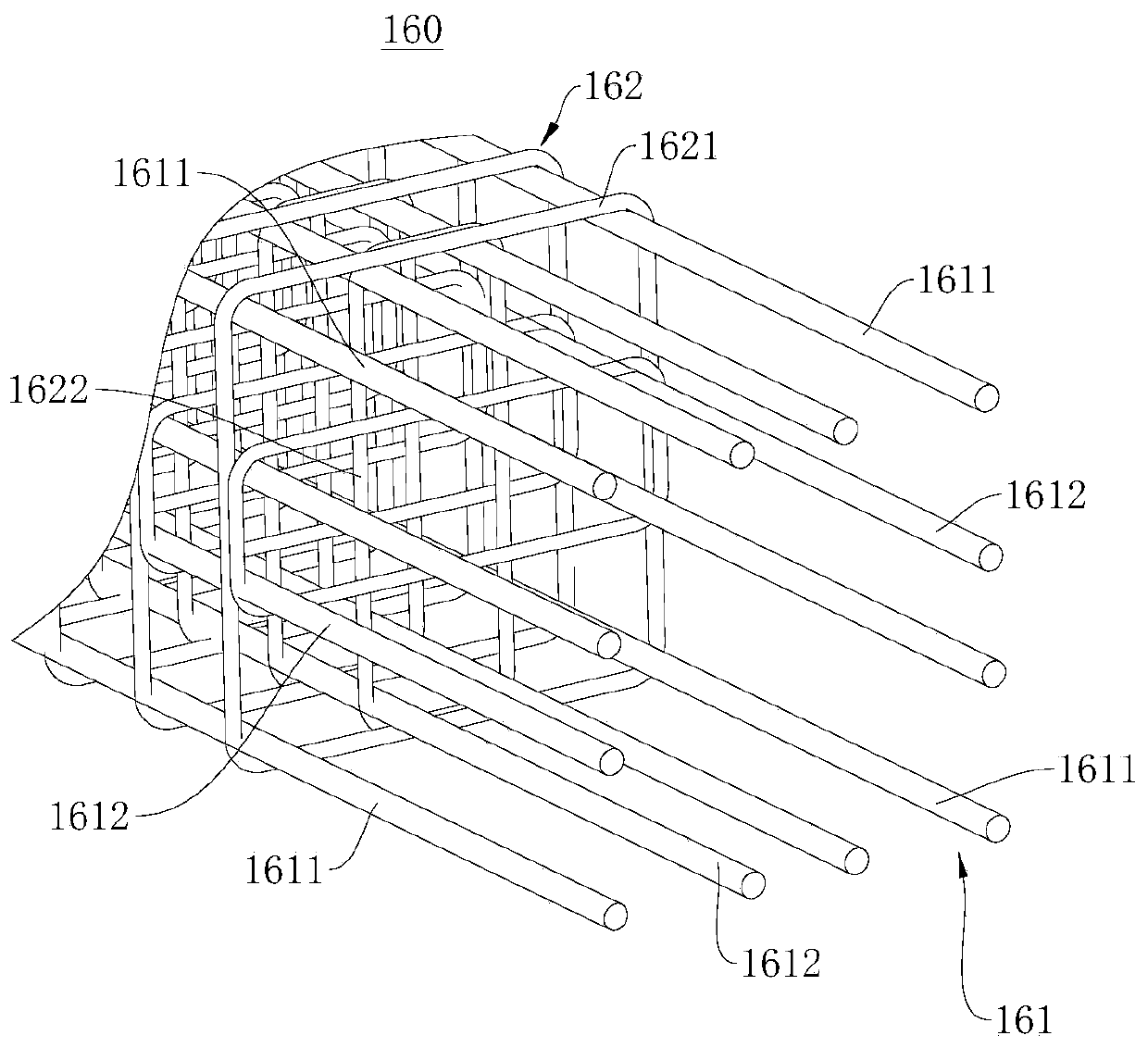

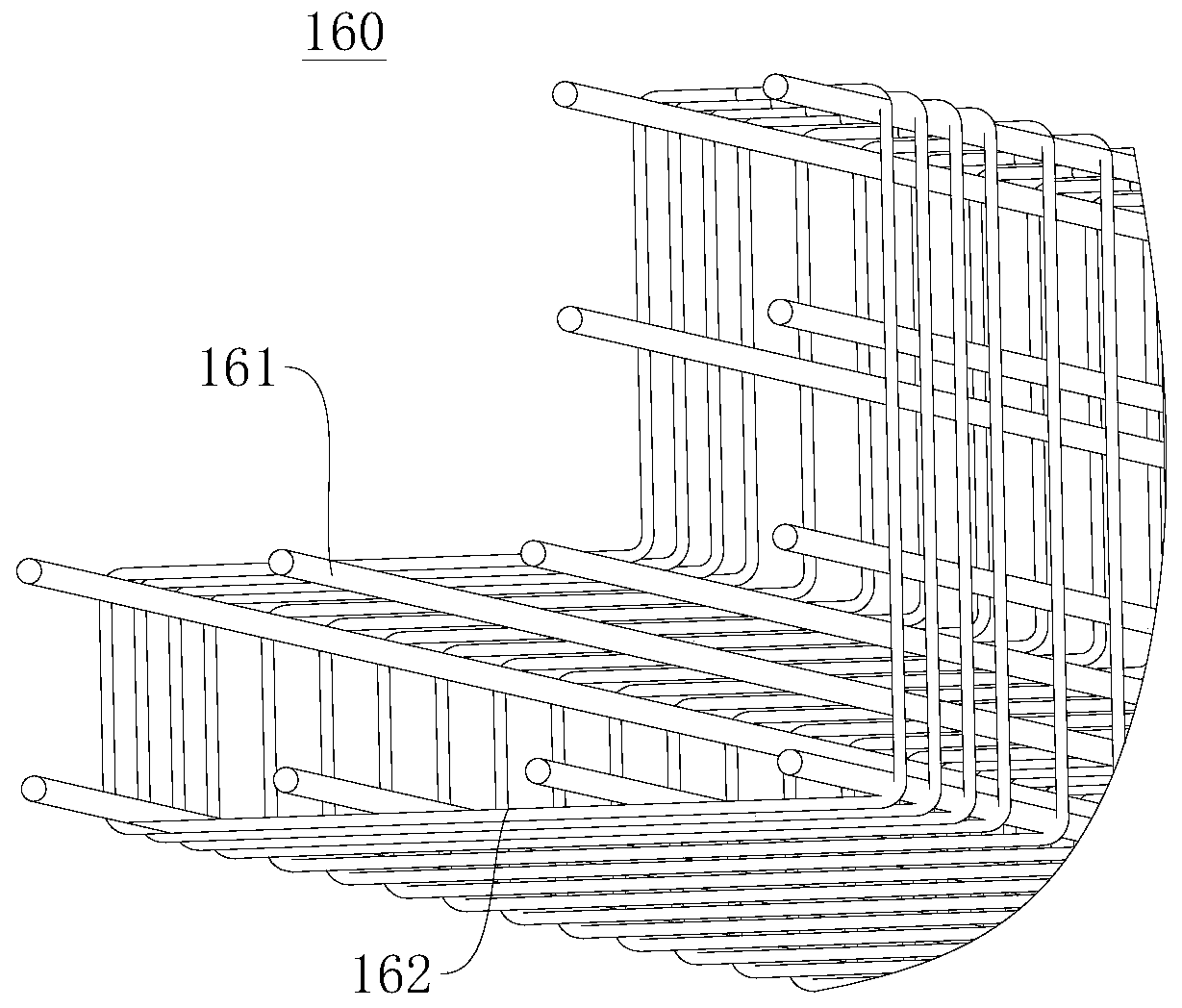

[0042] figure 1 The schematic diagram of the layout and structure of the cylindrical steel cage production system 100 provided in this embodiment. Please refer to figure 1 , the present embodiment provides a cylindrical reinforcement cage production system 100, which includes an automatic welding device 140 and a fixing device 150 arranged side by side with the automatic welding device 140. During production, the automatic welding device 140 is used to complete the welding and fixing of the stirrup 162 and the first longitudinal bar 1611, thereby making a semi-finished reinforcement cage 163 to realize the shaping of the reinforcement cage 160; the semi-finished reinforcement cage 163 is transferred to the fixing device 150 , to fix the steel cage 160 and the second longitudinal bar 1612, thereby making the finished product of the steel cage, and completing the production of the steel cage 160. By dividing the fixing of the longitudinal bars 161 and stirrups 162 into two ste...

Embodiment 2

[0060] Figure 7 It is a step diagram of the production method of the cylindrical reinforcement cage provided in this embodiment. Please refer to Figure 7 , this embodiment provides a method for producing a cylindrical reinforcement cage, which can be realized by using the cylindrical reinforcement cage production system 100 provided in Embodiment 1. The production method of the cylindrical reinforcement cage provided by the present embodiment is further described below:

[0061] S1: intercepting a plurality of longitudinal ribs 161 with a preset length.

[0062] The steel bar is cut by using an automatic sawing and threading machine 110 to obtain a longitudinal bar 161 with a preset length. The value of the preset length is specifically set according to user requirements. It can be understood that in other embodiments, steel bars with a preset length can also be directly purchased as the longitudinal bars 161 without cutting again.

[0063] S2: Process threads on both e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com