Automatic docking system with floating sealing

An automatic docking and floating sealing technology, which is applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of unsatisfactory airtightness, dust leakage, and unsatisfactory docking methods, so as to reduce the probability of pollution, reduce labor costs, and improve productivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

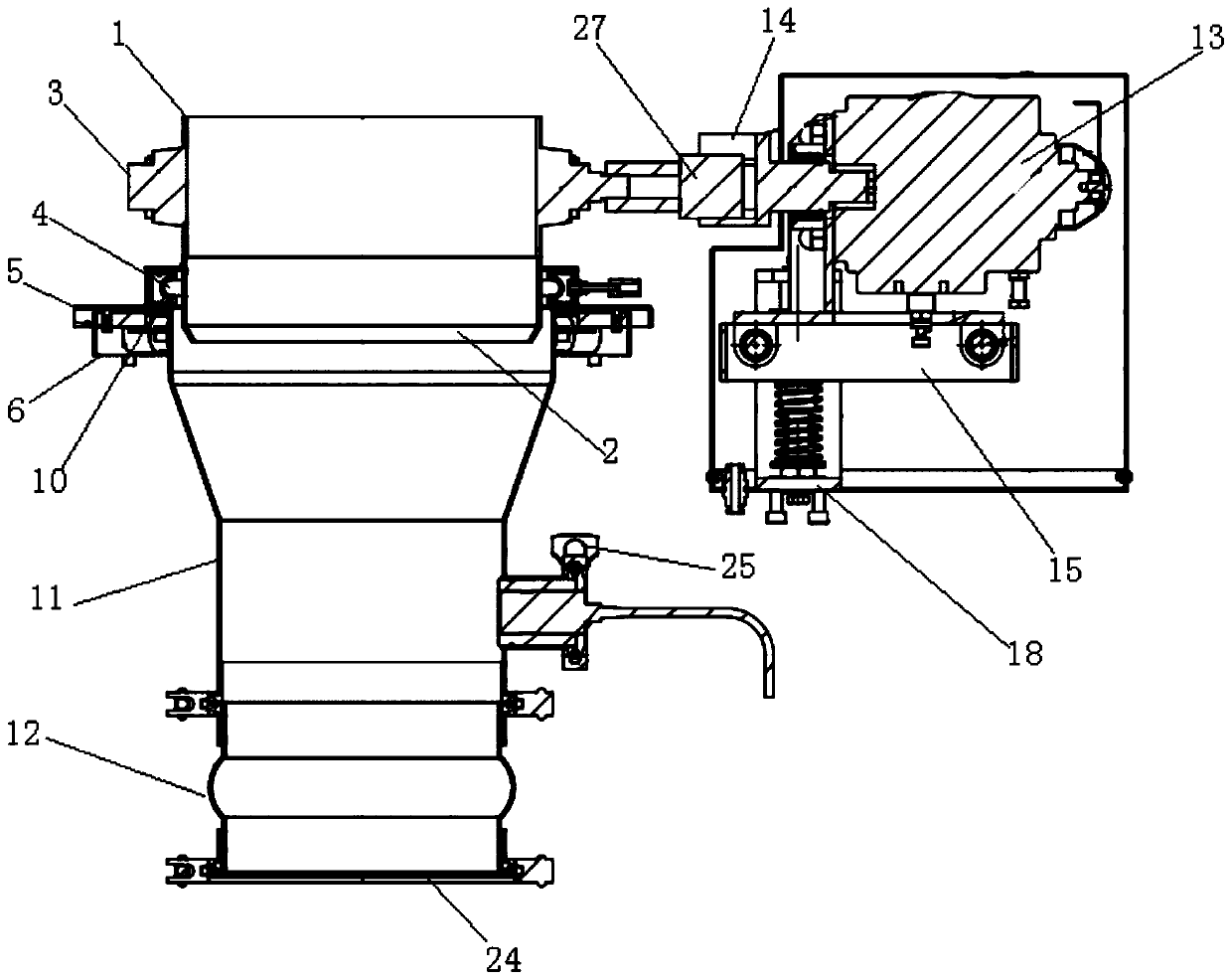

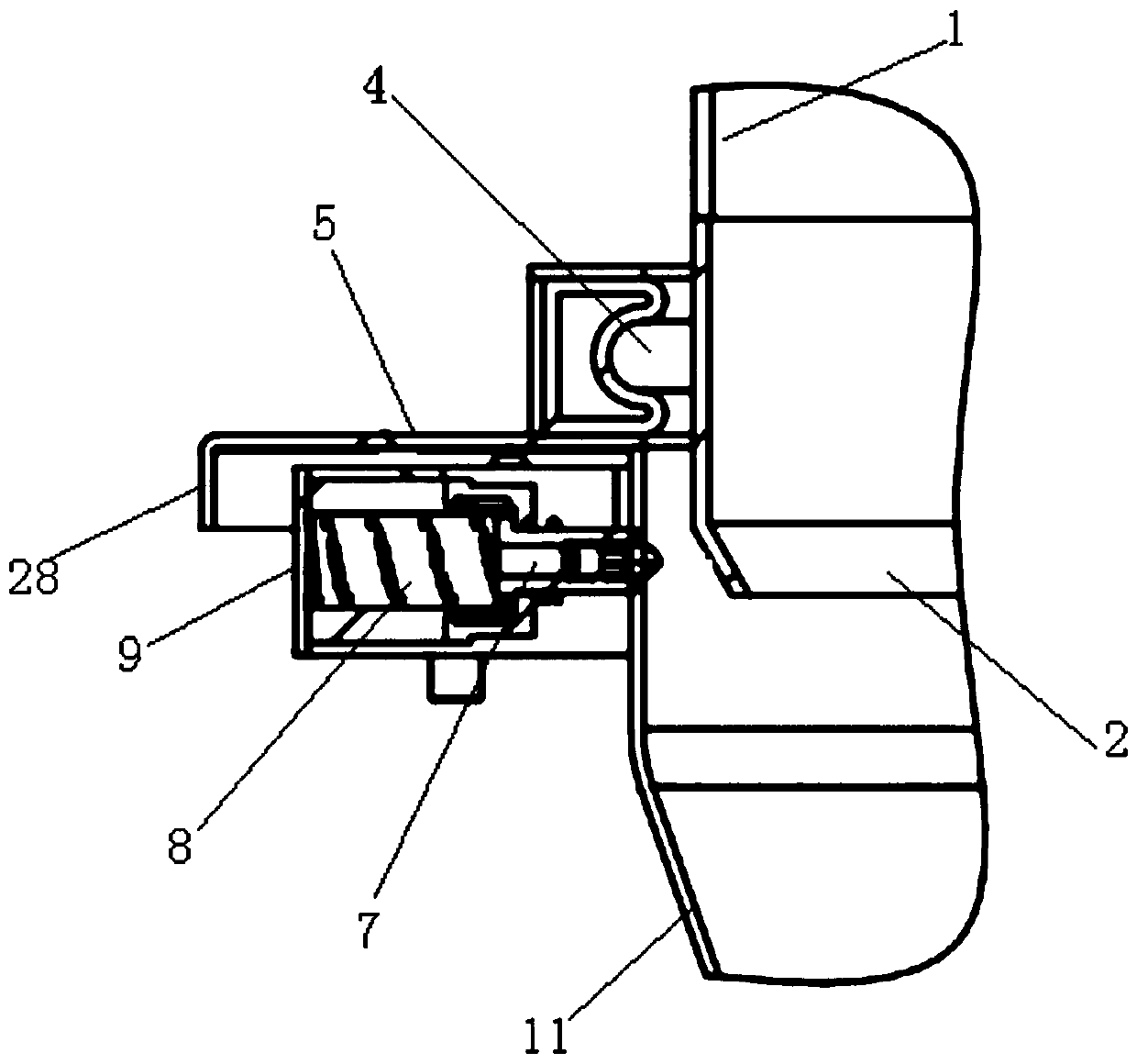

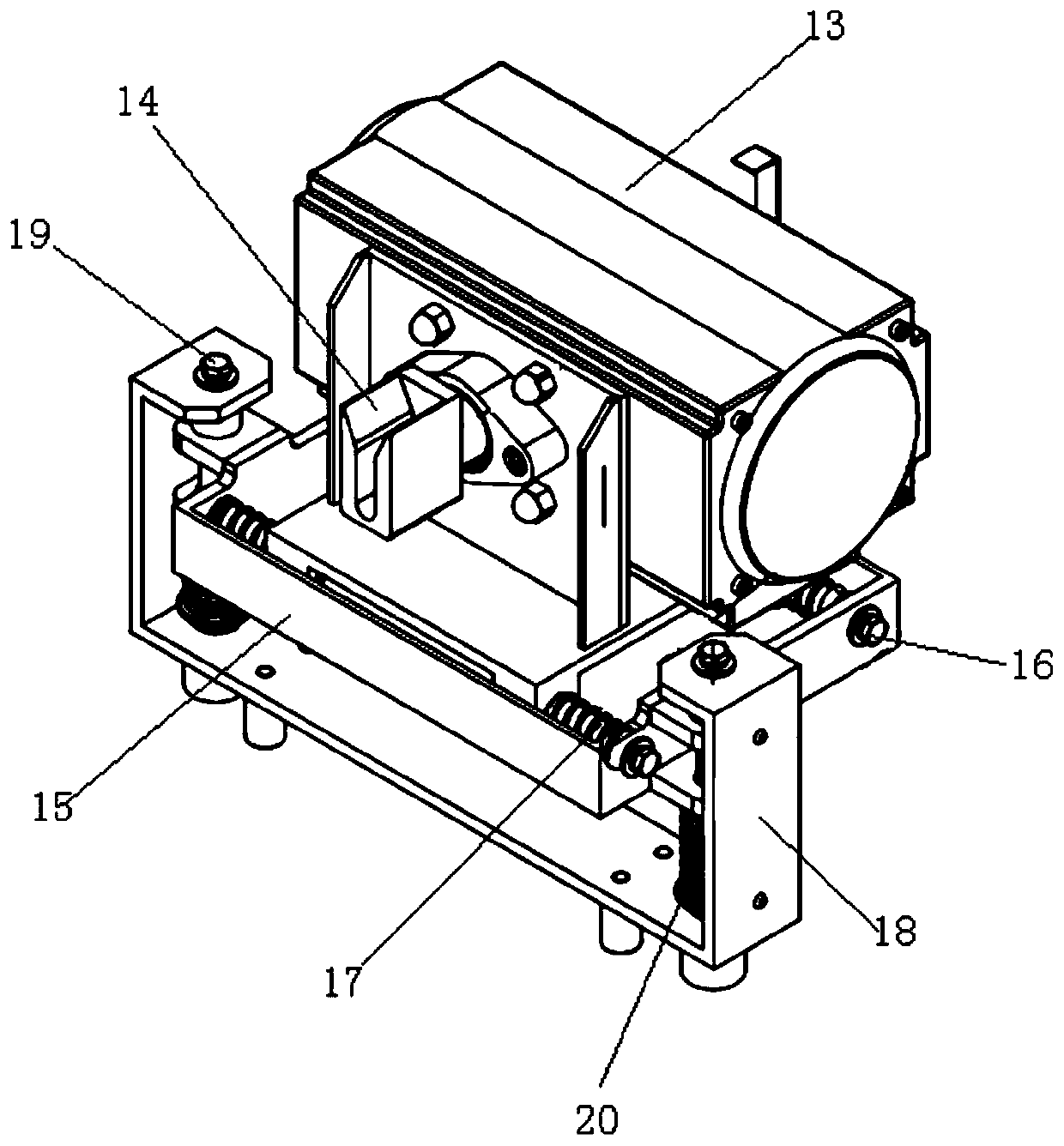

[0023] like Figures 1 to 4 As shown, a floating seal automatic docking system is provided in this embodiment, including a controller, a silo 1 and a material receiving device 21; the docking system also includes a docking device arranged on the material receiving device 21 and a The drive device connected to the silo 1, the drive device is connected to the switch valve 3 on the silo 1 to control the opening and closing of the feed port 2 of the silo 1; the docking device includes a floating part, an air bag 4 and the return part 6, the floating part is correspondingly sleeved on the outer periphery of the discharge port 2, the airbag 4 and the floating part are coaxially sleeved on the outer periphery of the discharge port 2, the floating part and the The return part 6 is fixedly connected, the floating part is slidably connected with the material receiving device 21, the return part 6 is fixedly connected with the material receiving device 21, the controller is connected wit...

Embodiment 2

[0049] In this embodiment, the use process of the docking system is as follows: the silo 1 is slowly lowered from top to bottom by an automatic device (such as a robot or an automatic manipulator), and within a certain size deviation range, under the guidance of the silo guide plate 22, The feeding port 2 falls into the encirclement of the air bag 4, and then the wedge-shaped handle 27 of the butterfly valve is automatically guided into the lever 14; the position sensor 26 detects that the material bin 1 is docked with the material receiving device 21, and the controller controls the air nozzle to move toward the air bag 4. Inflate, the airbag 4 expands and pushes the floating cover plate 5 to move horizontally until the airbag 4 is fully inflated and hugs the feeding port 2 tightly to form an airtight seal; then the controller controls the action of the actuator 13, and the actuator 13 drives the action of the lever 14 to realize the opening of the butterfly valve , the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com