Automatic butting device and butting method of cast-in-situ bored pile reinforcement cages

A technology of bored cast-in-place piles and docking devices, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc. It can solve the problems of reduced engagement length between steel bar threads and sleeves, slow docking speed, cumbersome operations, etc., and saves machinery. The effect of reducing shift costs, reducing pile-forming time, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

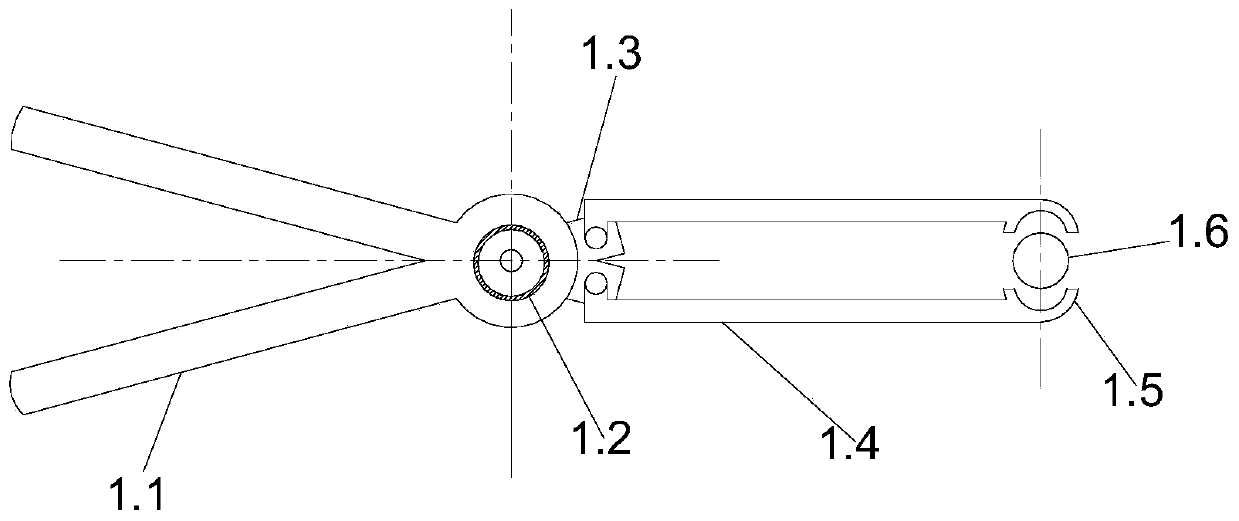

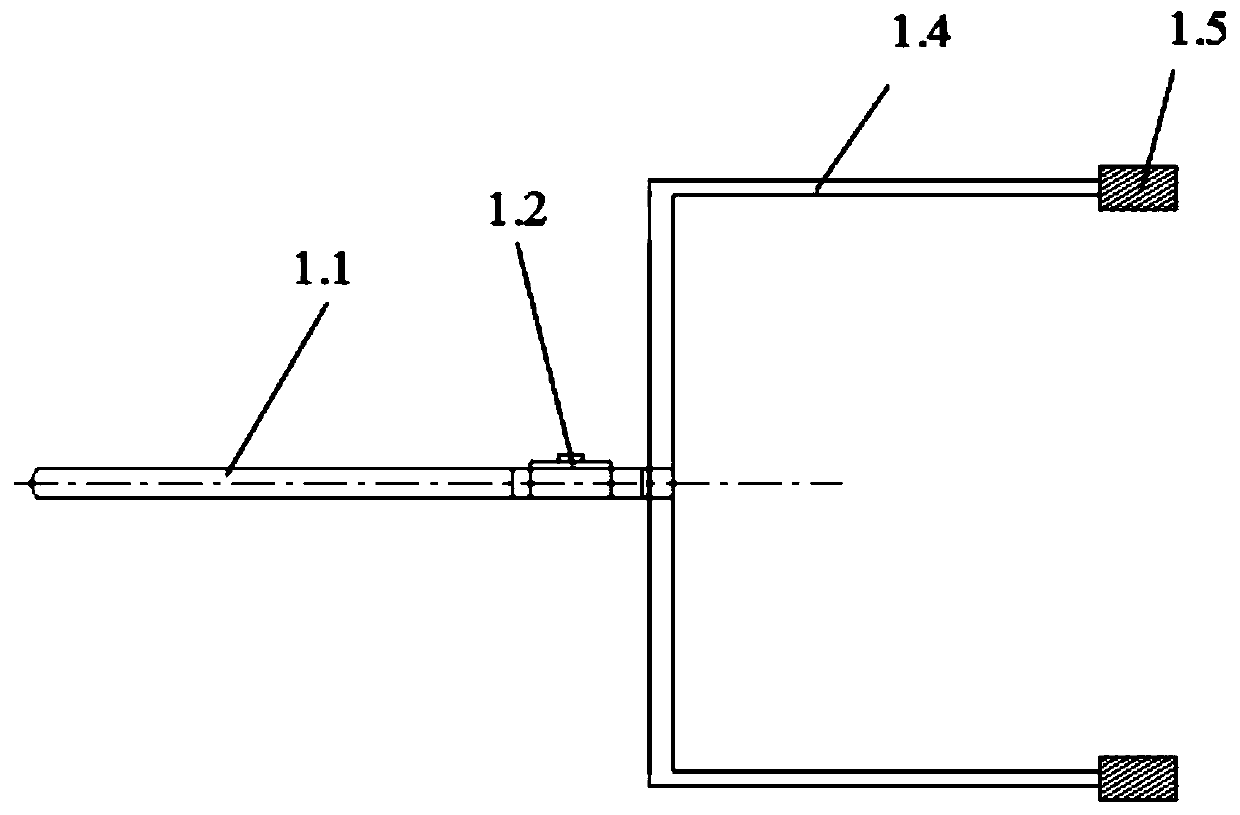

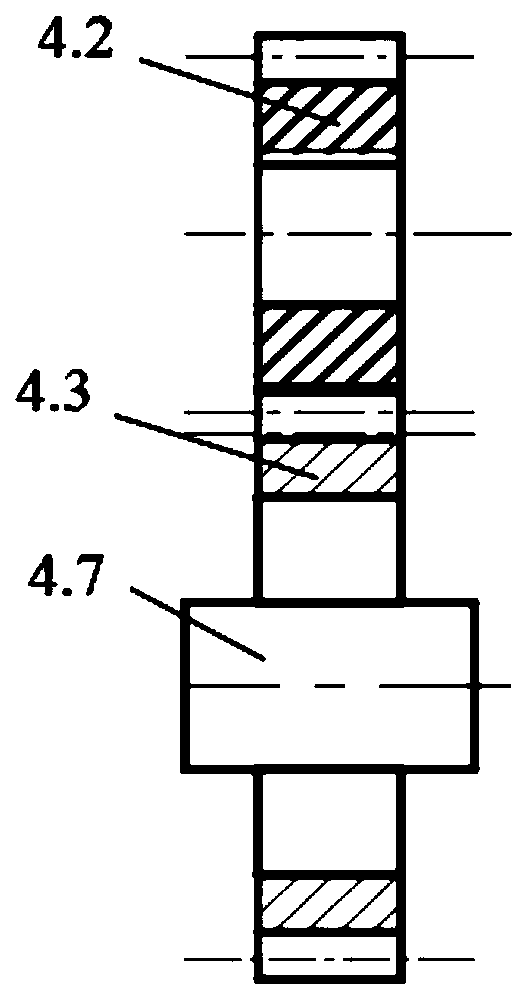

[0035] Such as Figure 1 to Figure 8 As shown, the embodiment of the present invention discloses an automatic docking device for reinforced cages of bored piles, including a clamping part 1, a sleeve and an automatic screwing mechanism 4, and the clamping part 1 includes a scissor arm 1.1, an automatic locking mechanism 1.2 and the clamping mechanism, two scissor arms 1.1 are connected at one end by an automatic locking mechanism 1.2, the central axis of the automatic locking mechanism 1.2 is the scissors shaft (fulcrum), and the automatic locking mechanism 1.2 is a purchased part, which is a rotating The locking mechanism can be locked in reverse and unlocked by itself during the rotation. The clamping mechanism is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com