Full-automatic testing device for water testing of faucet

A fully automatic test and faucet technology, which is applied in the direction of measuring device, fluid tightness test, machine/structural component test, etc. It can solve the problems of not improving the detection efficiency, long faucet time, and unable to guarantee the quality of the faucet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

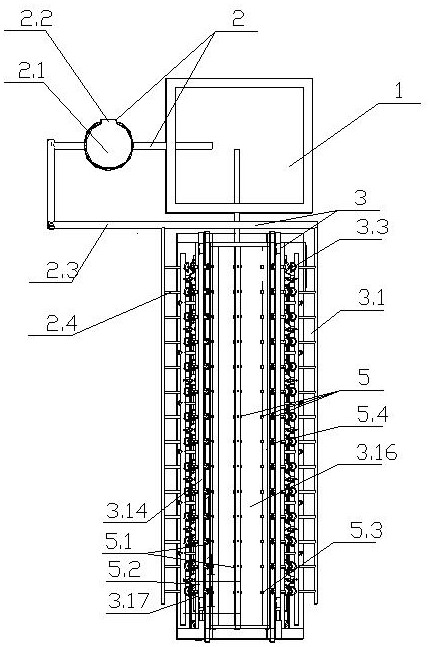

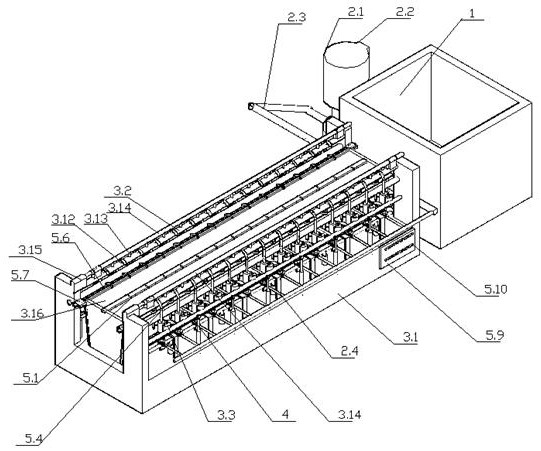

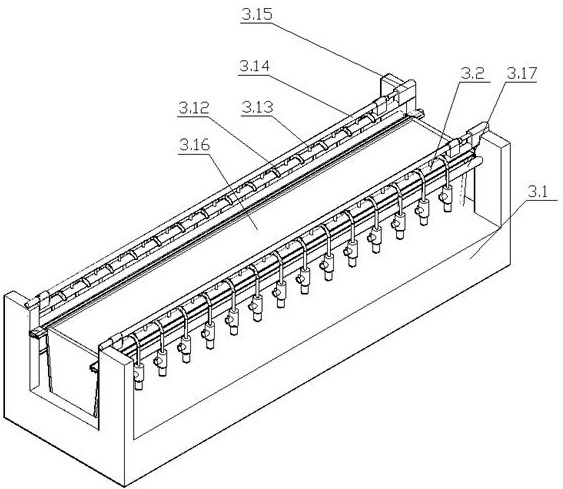

[0016] Such as Figure 1-7As shown, a fully automatic testing device for faucet water testing, including a water tank 1, a water testing system 2, a faucet placement frame 3 and a detection system 5, wherein the outer wall on the right side of the water tank 1 is fixed with a water testing device by means of bolt fastening. System 2, the water testing system 2 includes a booster pump 2.1, a water passage pipe 2.3 and a shunt pipe 2.4, the water passage pipe 2.3 communicates with the bottom of the water tank 1, and the water passage pipe 2.3 is fixed with a booster pump 2.1 through a threaded interface, increasing The pressure pump 2.1 is connected to the controller 2.2 through wires (the controller 2.2 controls the pressure applied by the booster pump 2.1 on the water pipe 2.3, so that it is convenient to adjust the pressure during detection. The controller 2.2 is a single-chip microcomputer 89-C51. The pump 2.1 realizes gradual pressurization through the controller 2.2), the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com