A vibrator with easy-to-control depth and range of action

A technology of action depth and vibrating rod, applied in manufacturing tools, construction material processing, construction, etc., can solve the problems of slow vibrating efficiency, labor-consuming, inaccurate control of vibrating spacing, etc., and achieve convenient and fast Disassembly and assembly, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

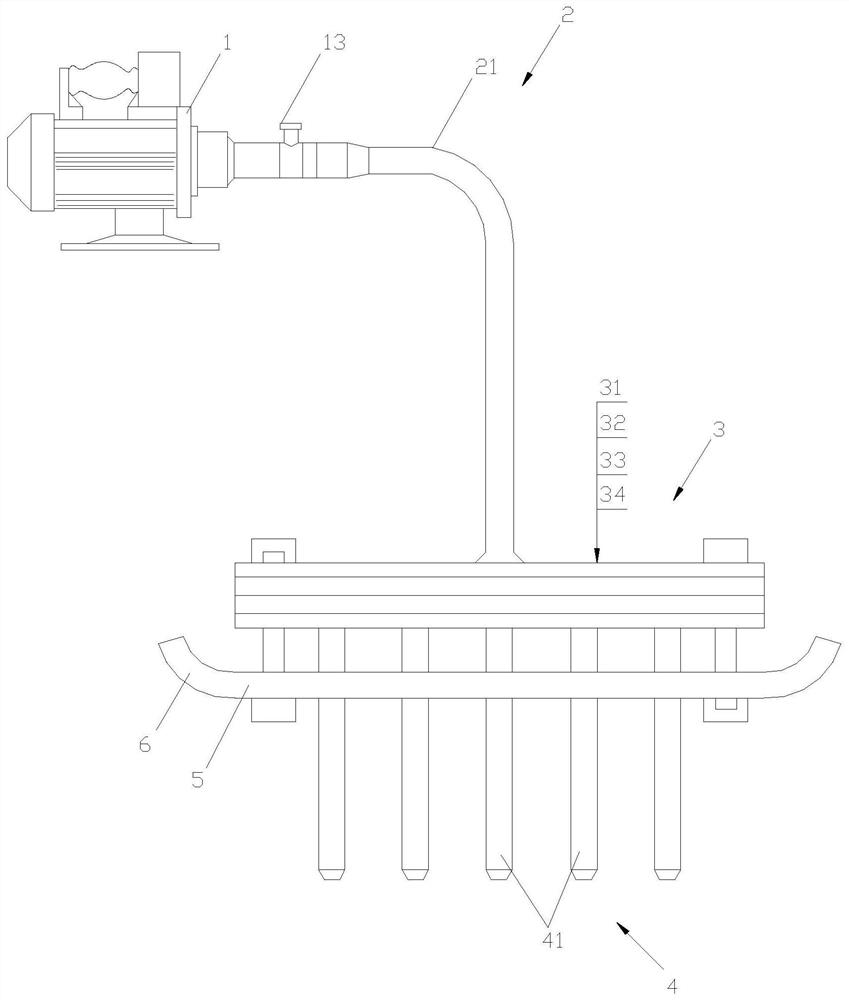

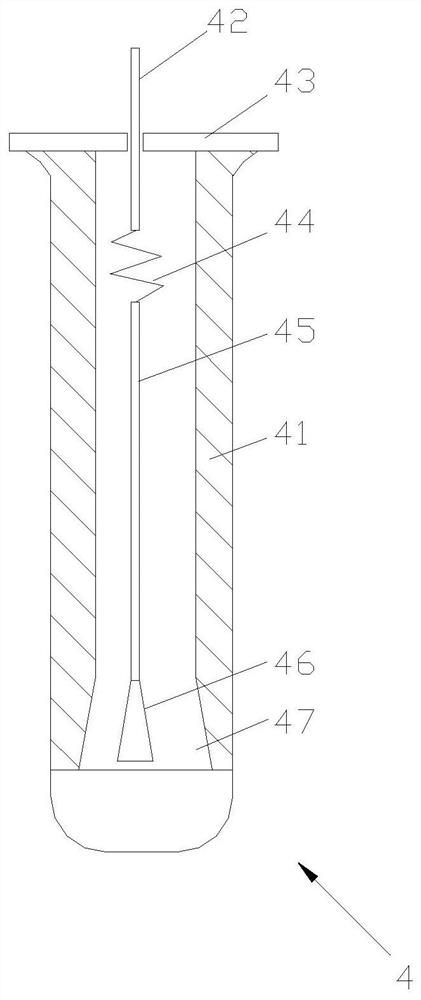

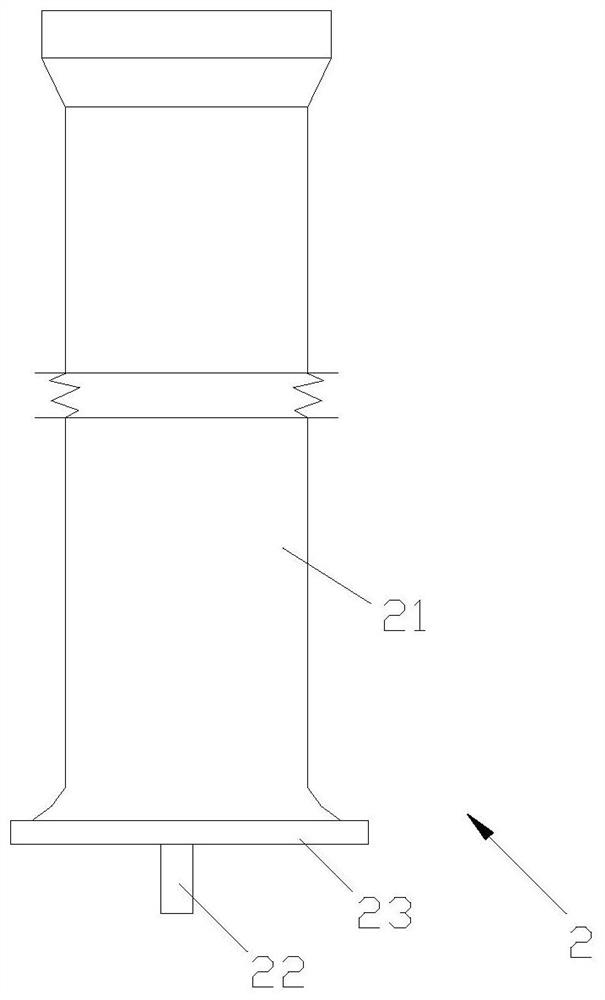

[0031] Embodiment of the present invention: a vibrator with easy-to-control depth and range of action, constituted as Figure 1 to Figure 5 As shown, it includes a motor 1, a flexible shaft transmission mechanism 2, a linkage mechanism 3 and a vibrating rod 4. The motor 1 is connected to the linkage mechanism 3 through a flexible shaft transmission mechanism 2. The flexible shaft transmission mechanism 2 includes a hose 21 and a primary Transmission shaft 22, the output shaft of the motor 1 is provided with a clip 13, one end of the hose 21 is fixed by the clip 13 of the motor 1, one end of the primary transmission shaft 22 is connected with the output shaft of the motor 1, The several vibrating rods 4 are detachably connected to the linkage mechanism 3 .

[0032] The linkage mechanism 3 includes an upper cover plate 31, a middle pressure plate 32, a middle support plate 33 and a lower bottom plate 34 arranged in sequence from top to bottom, see Figure 4 and Figure 5, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com