Vertical vibration forming process and forming device for reinforced concrete pipe

A technology for reinforced concrete pipes and molding equipment, which is applied in reinforcement molding, ceramic molding machines, manufacturing tools, etc., can solve problems such as inability to fully remove air holes in concrete pipes, affecting the quality of reinforced concrete pipes, and unsatisfactory vibrating effects. The effect of good vibrating effect, improving production efficiency and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

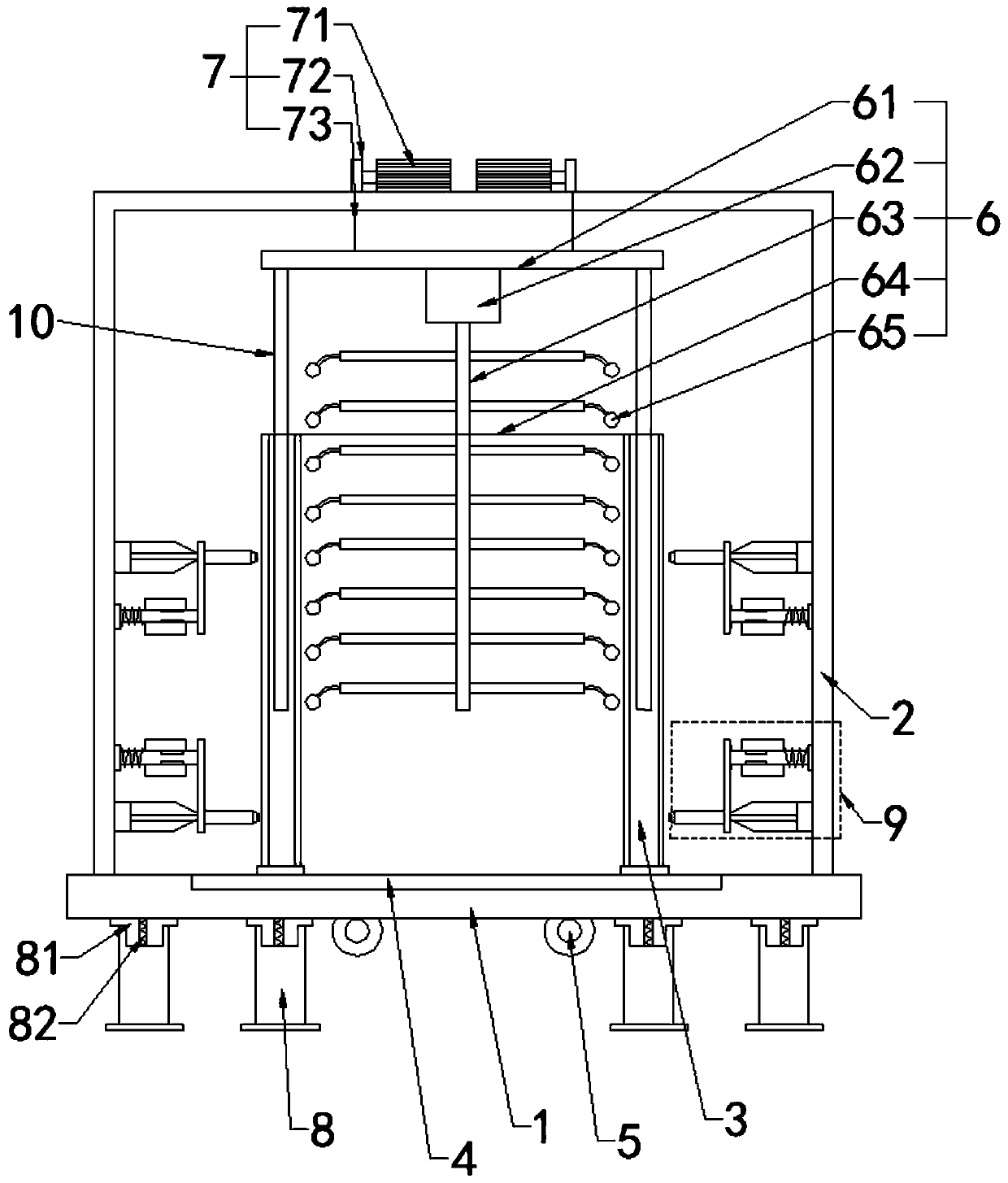

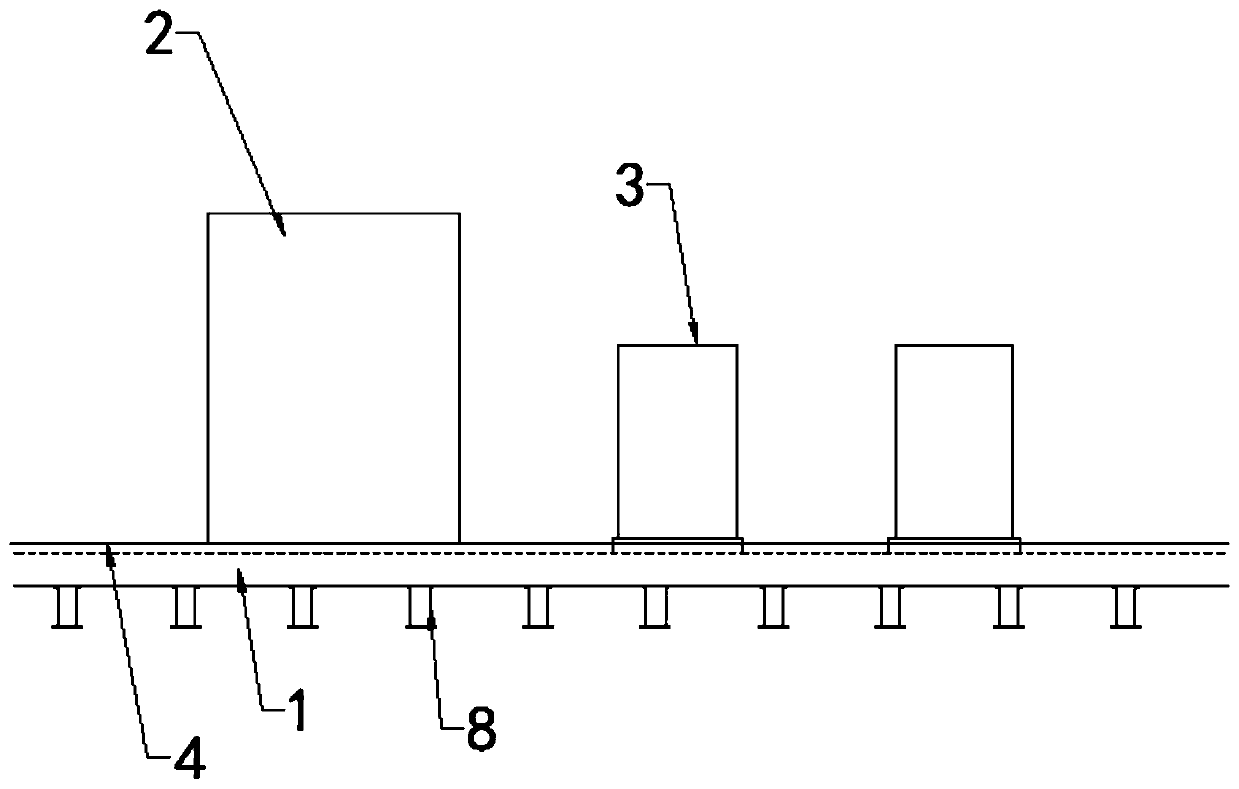

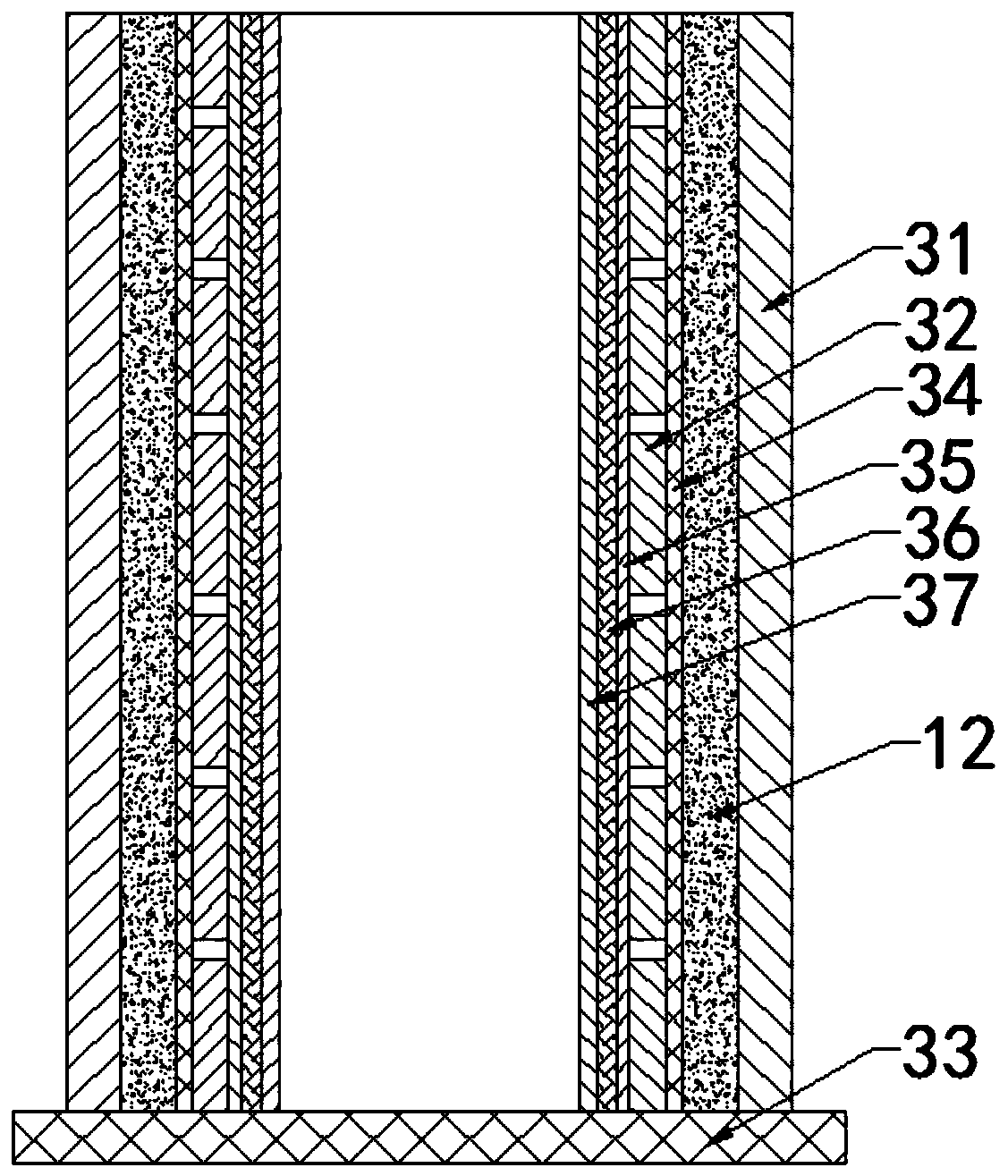

[0029] Such as Figure 1~2 As shown, the present invention discloses a vertical vibrating forming equipment for reinforced concrete pipes. In the embodiment of the present invention, it includes a base 1 and a support frame 2 fixed on the base 1, a pipe mold 3 and a vibrating device. The base 1 is provided with a conveying slide rail 4 for conveying concrete pipes, the conveying slide rail 4 slides on the base 1 for conveying, the pipe mold 3 is installed on the conveying slide rail 4, and the support frame 2 is A rectangular frame with front and rear openings and closed surroundings, the conveying slide rail 4 passes through the support frame 2, and the conveying slide rail 4 can transport the pipe mold 3 from one opening of the support frame 2 to another opening; the vibrating The device includes two sets of mechanical vibrators 5 installed at the lower end of the base 1, the first knocking assembly 6 set in the support frame 2, and the lifting assembly 7 set on the support ...

Embodiment 2

[0038] The invention discloses a vertical vibration molding equipment for reinforced concrete pipes. In an embodiment of the invention, it includes a base 1, a support frame 2 fixed on the base 1, a pipe mold 3 and a vibrating device. The base 1 is provided with a conveying slide rail 4 for conveying concrete pipes, the conveying slide rail 4 slides on the base 1 for conveying, the pipe mold 3 is installed on the conveying slide rail 4, the support frame 2 is opened front and rear and A rectangular frame closed all around, the conveying slide rail 4 passes through the support frame 2, the conveying slide rail 4 can transport the pipe mold 3 from one opening of the support frame 2 to another opening; the vibrating device includes Two groups of mechanical vibrators 5 at the lower end of the base 1, the first knocking assembly 6 arranged in the support frame 2, and the lifting assembly 7 arranged on the support frame 2 and used to control the lifting of the first knocking assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com