A comprehensive treatment method for bottom water coning in high permeability zone, shutting down wells, blocking, dredging and production control

A comprehensive treatment, high-permeability technology, applied in chemical instruments and methods, production fluids, earth-moving drilling, etc., can solve the problems of scrapping oil and gas wells, casing deformation, affecting oil and gas production, etc. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In the present invention, there is no special limitation on the preparation method of the nitrogen foam, which can be prepared by a preparation method well known to those skilled in the art.

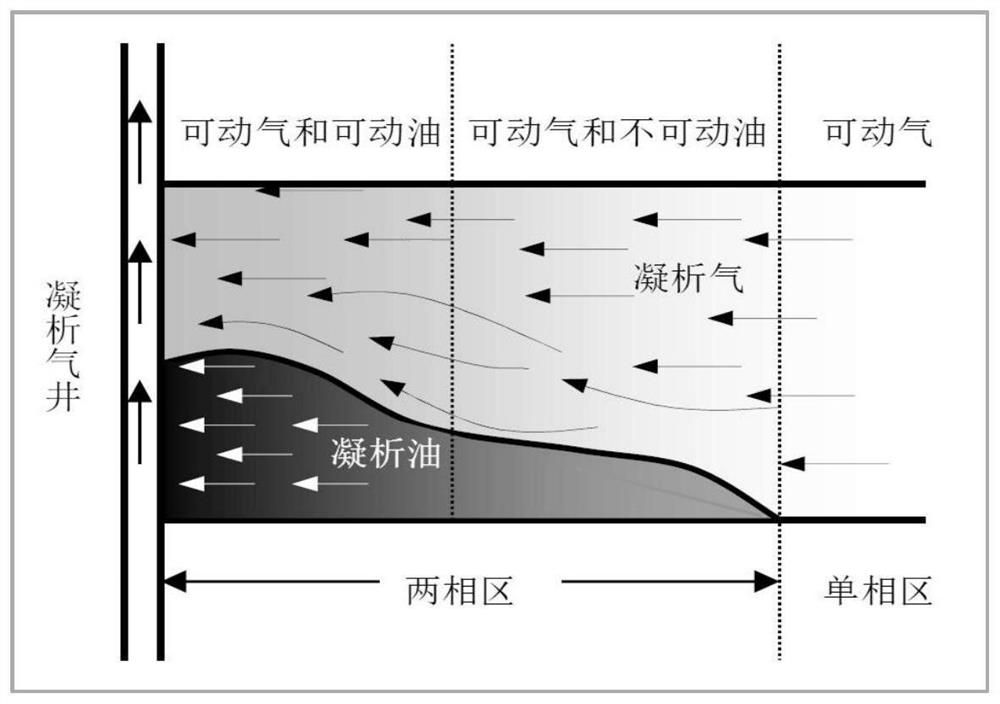

[0046] In the present invention, since the bottom water occupies the oil and gas flow channel, the nitrogen foam preferably completely blocks the bottom water coning channel, and the channel has no oil and gas flow, while the nitrogen foam can exist stably for a long time.

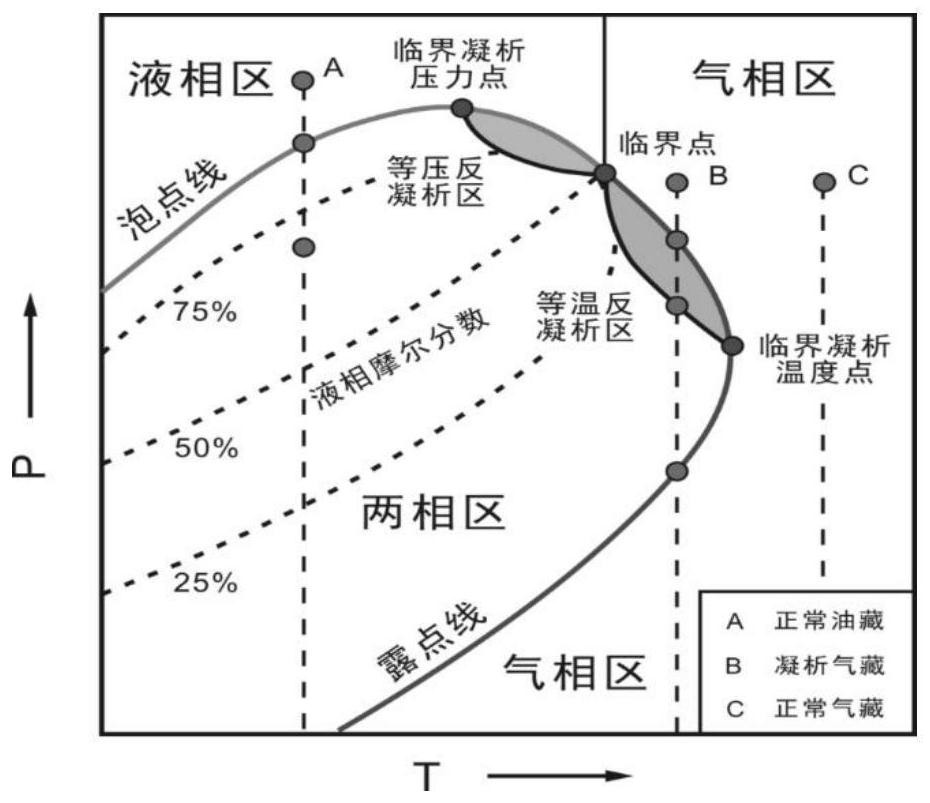

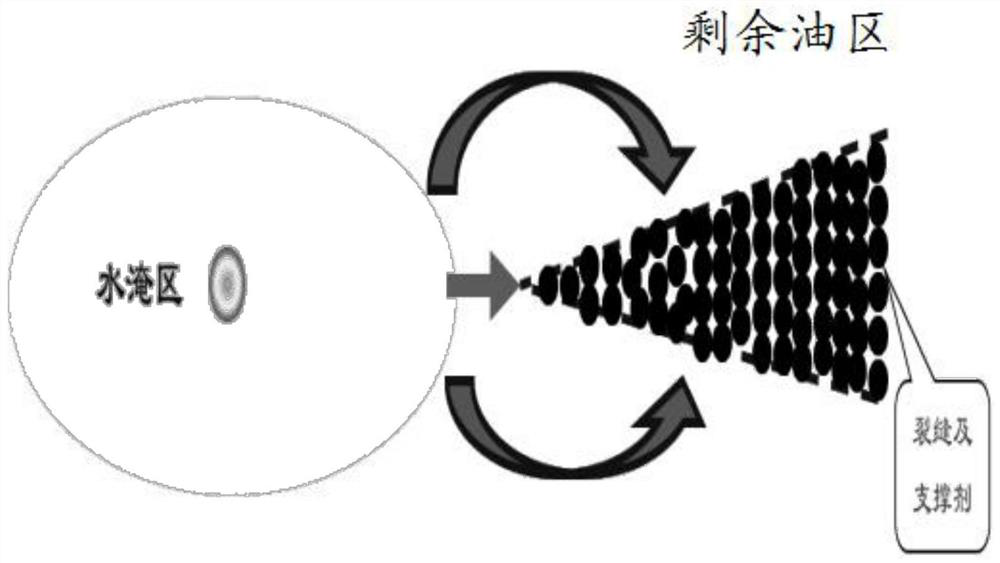

[0047] After the selective water shutoff is completed, the present invention uses high-pressure supercritical carbon dioxide to seismically break the reservoir in the high-permeability zone to realize hydrophobic flow.

[0048] In the present invention, during the seismic crushing, the pumping pressure of the supercritical carbon dioxide is preferably 75-100 MPa. In the present invention, during the seismic crushing, the action range of the supercritical carbon dioxide is preferably within the range of 500-700...

Embodiment

[0065] 1. Selective water shutoff-nitrogen foam water shutoff for the large outlet channel along the high permeability zone;

[0066] The fracture angle in the high permeability zone is 50-90°.

[0067] For active bottom water coning into oil and gas reservoirs, nitrogen foam water blocking technology can be used to produce high-strength foam water blocking layer, which can effectively block the water intrusion channel and prevent bottom water from coning along the high-permeability water channel again in the future production process .

[0068] Nitrogen foam is composed of dispersed phase (nitrogen), foaming agent (surfactant) and foam stabilizer (active jelly), and the mass ratio of nitrogen, surfactant and active jelly is 2:1:7.

[0069] Nitrogen foam is a selective water blocking agent that preferentially enters formations with high water saturation.

[0070] Nitrogen foam can exist stably in formations with high water saturation, but not in formations with high oil satu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com