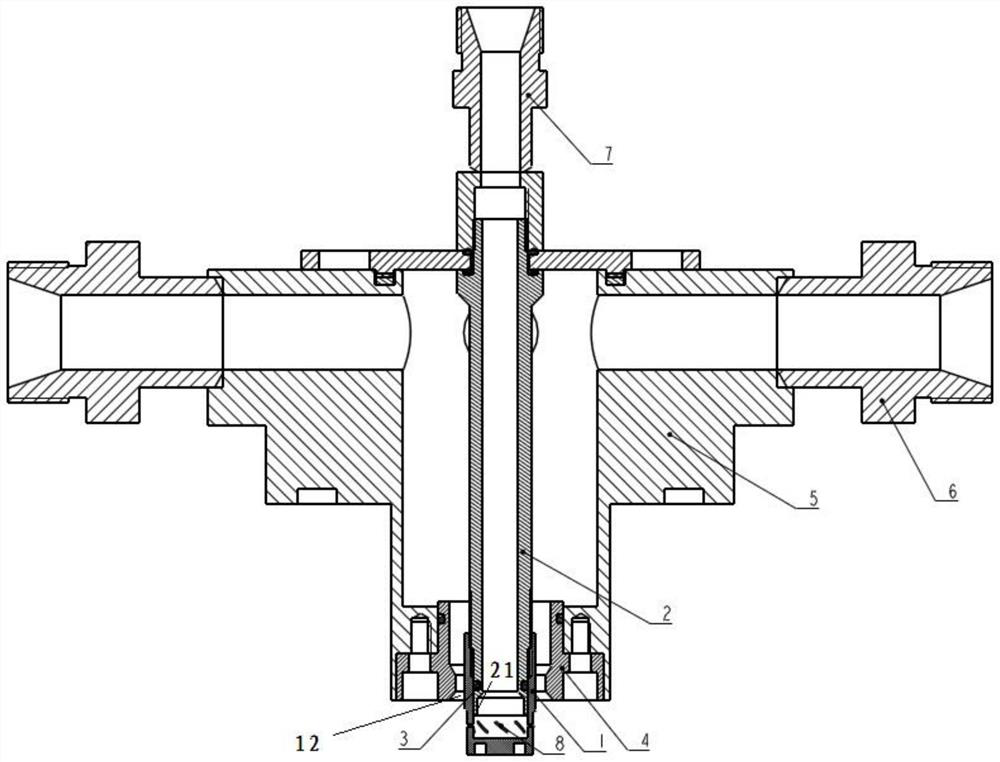

Head structure of a chute pintle injector

A technology of injector and pintle, which is applied in the field of pintle variable thrust engine design, can solve problems such as leakage of the pintle head and the mating surface of the cover plate, high process requirements, and difficult processing of injectors, etc., to achieve low The effect of propellant leakage rate, good experiment convenience, and reduced matching difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0024] The present invention provides a head structure of a chute-type pintle injector, one type of injection medium enters the axial nozzle through the axial nozzle joint 7, and the other type of injection medium enters the pintle nozzle 1 through the radial nozzle joint 6; Finally, an atomized impact is formed outside the pintle nozzle 1; it can reduce the difficulty of matching the structural parameters of the pintle injector, improve the reliability of the pintle work and the convenience of the ground cold and hot state experiment.

[0025] Such as figure 1 Shown is a cross-sectional view of a chute-type pintle injector. It can be seen from the figure that a head structure of a chute-type pintle injector includes a pintle nozzle 1, a central rod 2, a sealing structure 3, and an outer ring cover plate 4 , an injector housing 5, n radial nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com