Gear differential planetary gear reducer

A planetary gear reduction and gear technology, applied in the field of tooth difference planetary gear reducer, can solve the problems of limited friction transmission speed, small range of reduction ratio, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described below in conjunction with specific embodiments.

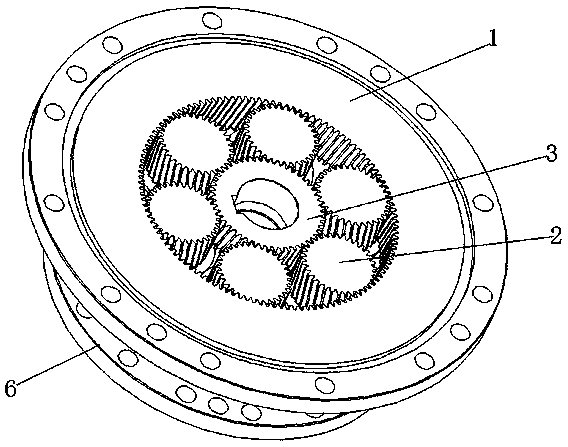

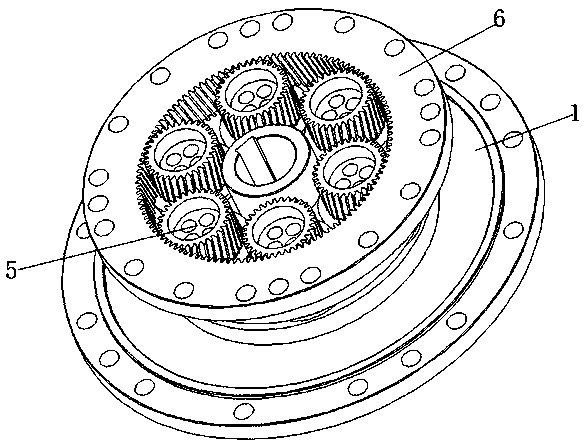

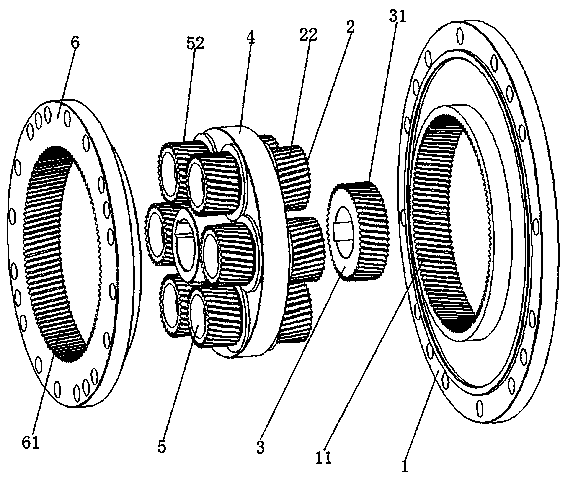

[0026] like Figure 1-4 As shown, a tooth difference planetary gear reducer includes a ring-shaped first-stage ring gear 1, and the upper end of the inner wall of the first-stage ring gear 1 is built with ring-shaped inner teeth 11 of the first-stage ring gear. The internal teeth 11 of the ring gear are meshed with at least two first-stage gears 2 arranged in a circle and in a convex shape, and the input gear 3 is meshed between the two first-stage gears 2, and the upper end of the first-stage gear 2 is fitted with a The first-stage bearing 21, and the first-stage bearing 21 is set in the circular input shaft 4, the upper end of the input shaft 4 is provided with a bearing hole 41 corresponding to the first-stage gear 2 and arranged in a circle, and the first-stage bearing 21 Set in the bearing hole 41, the bearing hole 41 is located at the other end of the set of primary bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com