Specialty printing device and specialty printing method

A kind of printing equipment and special technology, applied in the field of printing, can solve the problems of complicated structure, waste of hot stamping foil, etc., and achieve the effects of simple operation, high utilization rate, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

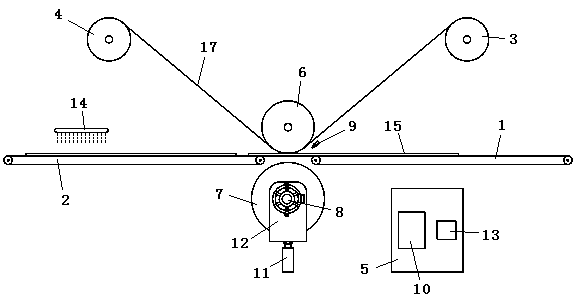

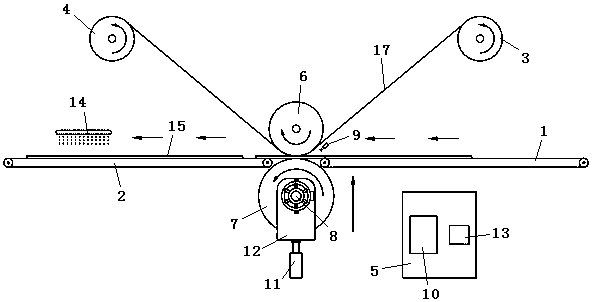

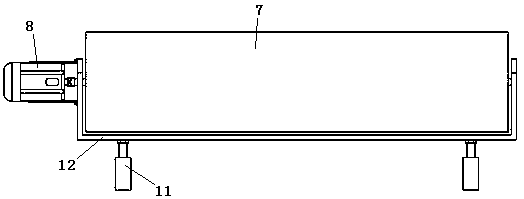

[0033] Example 1: as Figure 1~3 As shown, a special printing equipment includes a first paper feeding mechanism 1, a second paper feeding mechanism 2, a pressing mechanism, an unwinding roller 3, a winding roller 4 and a control cabinet 5; the pressing mechanism includes an upper pressure The roller 6 and the lower pressing roller 7, the first servo motor 8 drives and connects the lower pressing roller 7, the first paper feeding mechanism 1 and the second paper feeding mechanism 2 are arranged on both sides of the pressing mechanism, and the upper pressing roller 6 is close to the first There is an electronic eye 9 above this end of the paper feeding mechanism 1, and the electronic eye 9 is arranged obliquely to illuminate the tangent point of the upper pressing roller 6 and the lower pressing roller 7; the unwinding roller 3 and the winding roller 4 are arranged on the upper pressing roller 6. Above the two sides, a second servo motor (not shown in the drawings) is driven an...

Embodiment 2

[0039] Embodiment 2: a special printing method realized using the special printing equipment described in Embodiment 1,

[0040] Step 1: Before the cold stamping printing, the printing material 15 is firstly printed with UV varnish to form the information layer 16 through the screen printing equipment, and the information layer 16 protrudes from the surface of the printing material 15;

[0041] Step 2: The rolled hot stamping foil is installed on the unwinding roller 3, the foil film 17 is pulled open and passes through the bottom of the upper pressing roller 6, and is fixed on the winding roller 4;

[0042] Step ③: the printing material 15 reaches the first paper feeding mechanism 1 from the unloading end of the screen printing device, and moves to the end of the pressing mechanism through the first paper feeding mechanism 1;

[0043]Step ④: After the electronic eye 9 detects the information layer 16 on the printing material 15, it feeds back the signal to the controller 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com