Omni-directional motion large aircraft horizontal assembly docking 13 degrees of freedom hybrid attitude adjustment platform

A degree of freedom and large-scale technology, applied in the direction of aircraft assembly, etc., can solve problems such as prone to accidents, low control stability, and short moving distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

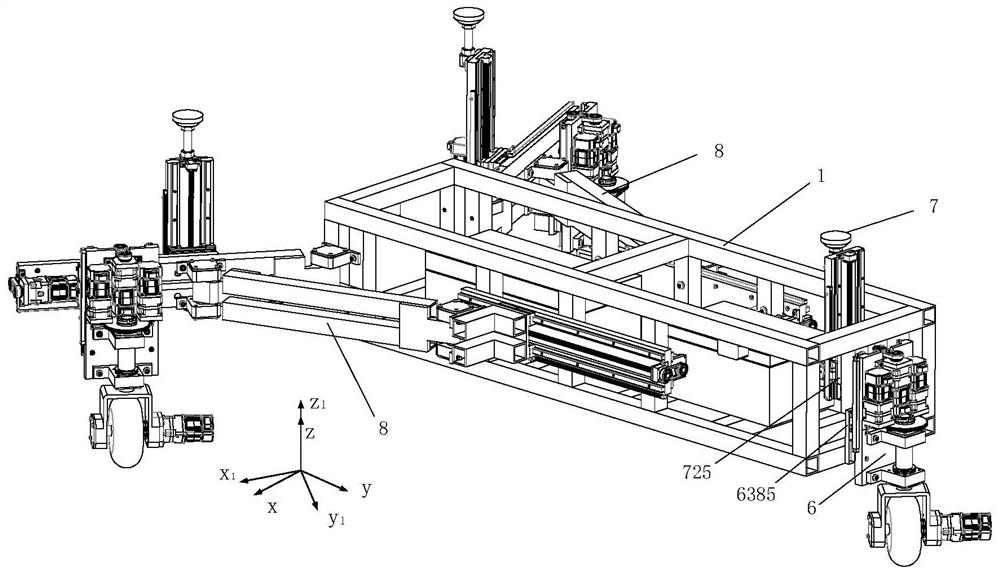

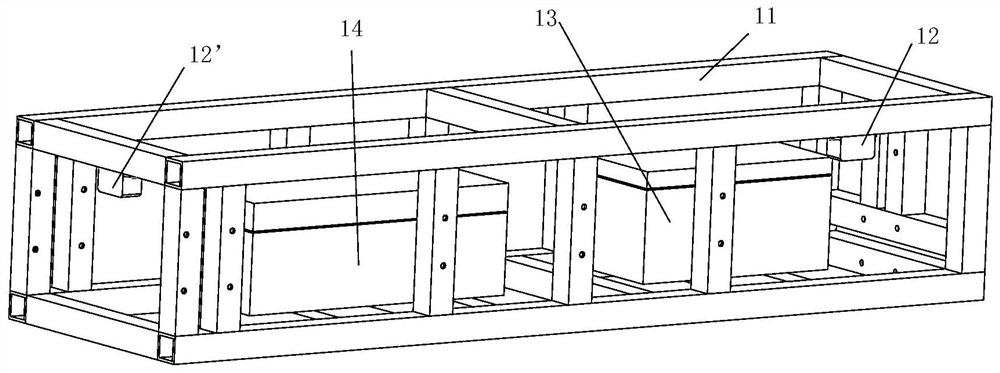

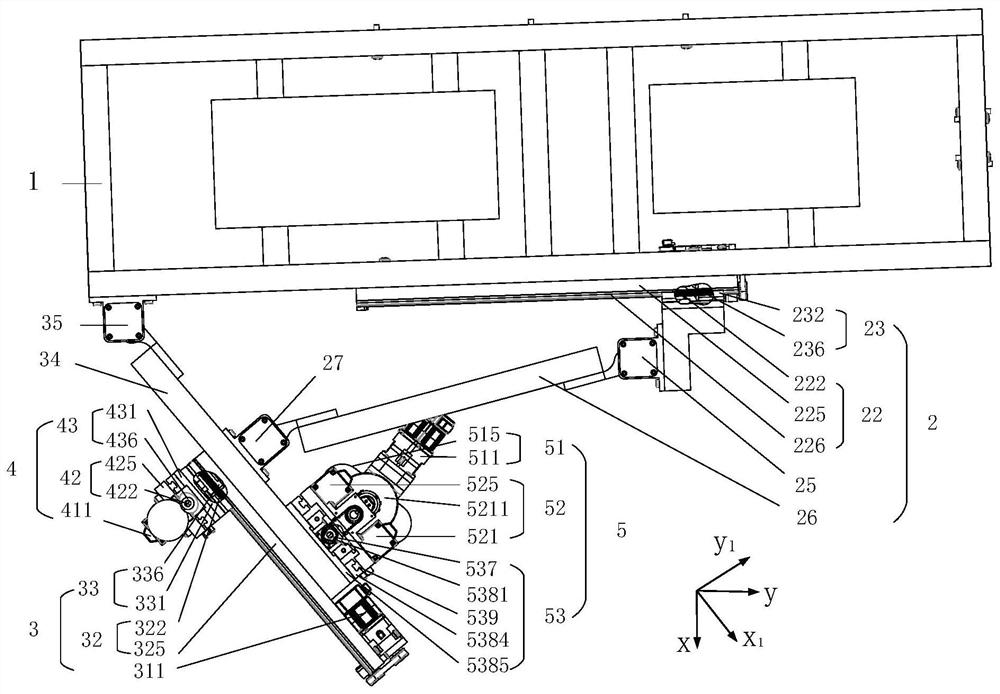

[0041] The invention provides a 13-degree-of-freedom hybrid attitude adjustment platform for horizontal assembly and docking of large aircraft with omnidirectional movement, such as figure 1 and figure 2 As shown, it includes a car body 1, two lift height position control devices 8, a front attitude adjustment leg module 6 and a front lift height control module 7, and the car body 1 includes a vehicle frame 11, a front posture detection module 12, a rear Attitude detection module 12', controller 13 and power supply module 14, the first end and the second end of vehicle frame 11 are respectively fixed with front attitude detection module 12 and rear attitude detection module 12', for real-time detection of vehicle body 1 Attitude, the controller 13 and the power mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com