Environmental-friendly cofferdam on working site

An on-site, environmentally-friendly technology that is applied to drilling equipment, boreholes/well components, earthwork drilling, etc., can solve problems such as secondary pollution, difficult treatment, and high cost, so as to reduce work intensity, improve labor efficiency, reduce Effect of Disposal Charges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

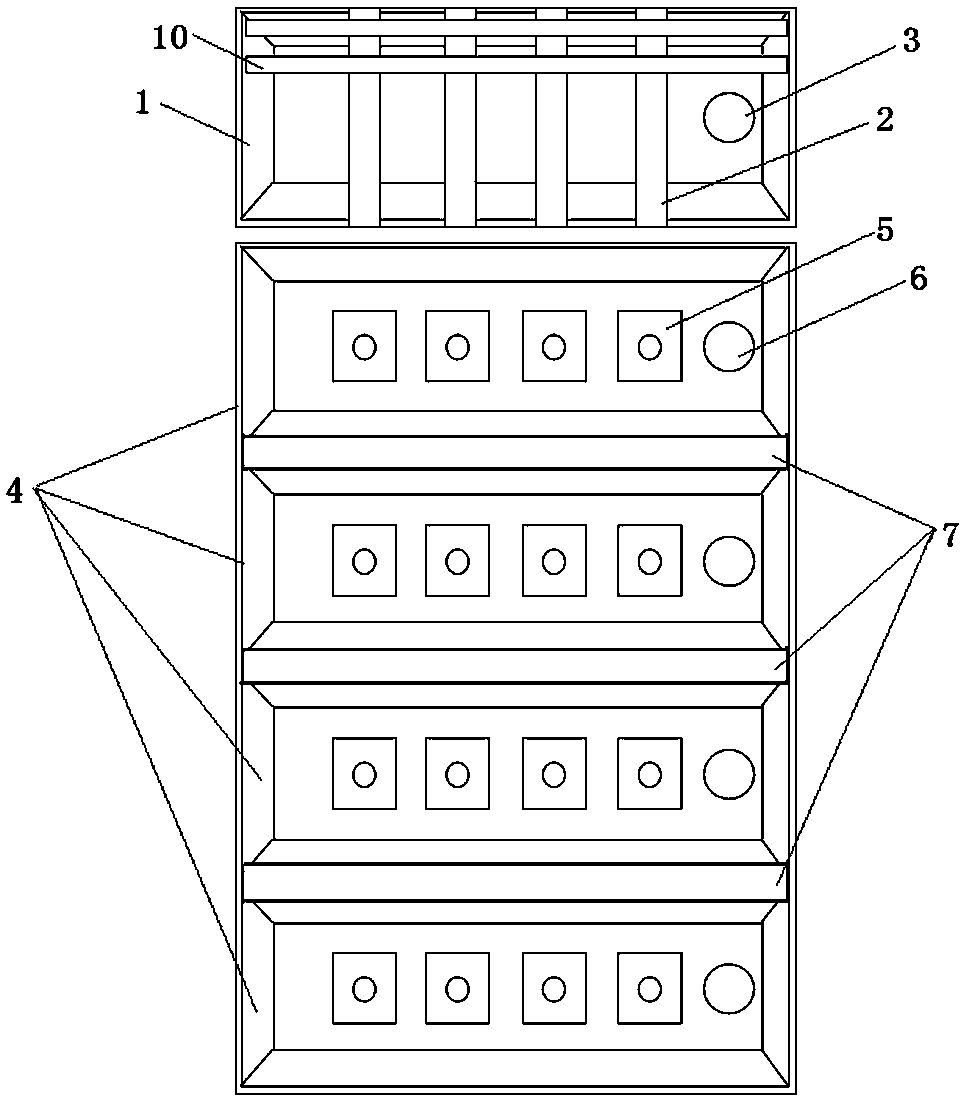

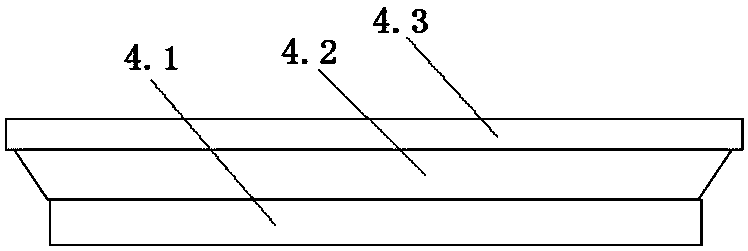

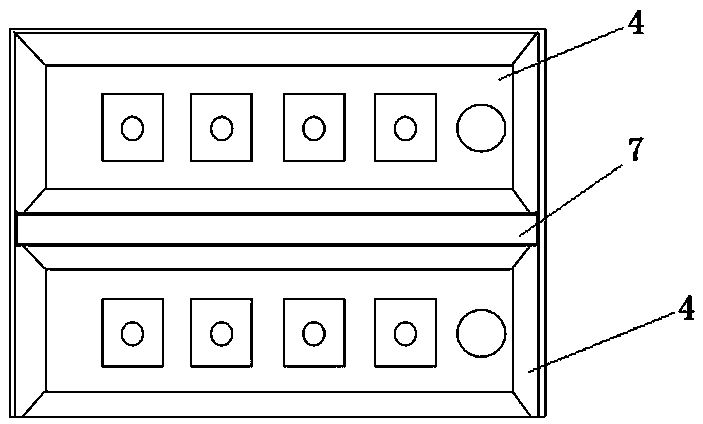

[0023] like figure 1 , the present invention includes a sucker rod placement area and a tubing placement area, where one or more sucker rod boat-shaped grooves 1 are placed in the sucker rod placement area, and one side of the sucker rod boat-shaped groove 1 is aligned with the wellhead, Four sucker rod fixing brackets 2 are welded in the oil rod boat-shaped groove 1, and the four sucker rod fixing brackets 2 are arranged at equal intervals. The sucker rod 10 is placed on the sucker rod fixing bracket 2, The end of the 1 is provided with a sucker rod sewage tank 3, four or more oil pipe ship-shaped grooves 4 are placed in the oil pipe placement area, and one side of the four or more oil pipe ship-shaped grooves 4 is aligned with the wellhead. Adjacent oil pipe ship-shaped grooves 4 are connected together by pinch plates 7. Four oil pipe adjustable fixing brackets 5 are welded in the oil pipe ship-shaped grooves 4. The four oil pipe adjustable fixing brackets 5 are arranged at ...

Embodiment 2

[0032] like figure 1 , the present invention includes a sucker rod placement area and a tubing placement area, where one or more sucker rod boat-shaped grooves 1 are placed in the sucker rod placement area, and one side of the sucker rod boat-shaped groove 1 is aligned with the wellhead, Four sucker rod fixing brackets 2 are welded in the oil rod boat-shaped groove 1, and the four sucker rod fixing brackets 2 are arranged at equal intervals. The sucker rod 10 is placed on the sucker rod fixing bracket 2, The end of the 1 is provided with a sucker rod sewage tank 3, four or more oil pipe ship-shaped grooves 4 are placed in the oil pipe placement area, and one side of the four or more oil pipe ship-shaped grooves 4 is aligned with the wellhead. Adjacent oil pipe ship-shaped grooves 4 are connected together by pinch plates 7. Four oil pipe adjustable fixing brackets 5 are welded in the oil pipe ship-shaped grooves 4. The four oil pipe adjustable fixing brackets 5 are arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com