Heat-conducting silica gel sheet and preparation method and application thereof

A thermally conductive silicone sheet, high thermal conductivity technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problem of low compression ratio of thermally conductive silicone sheets, reduce processing difficulty, and improve compression ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

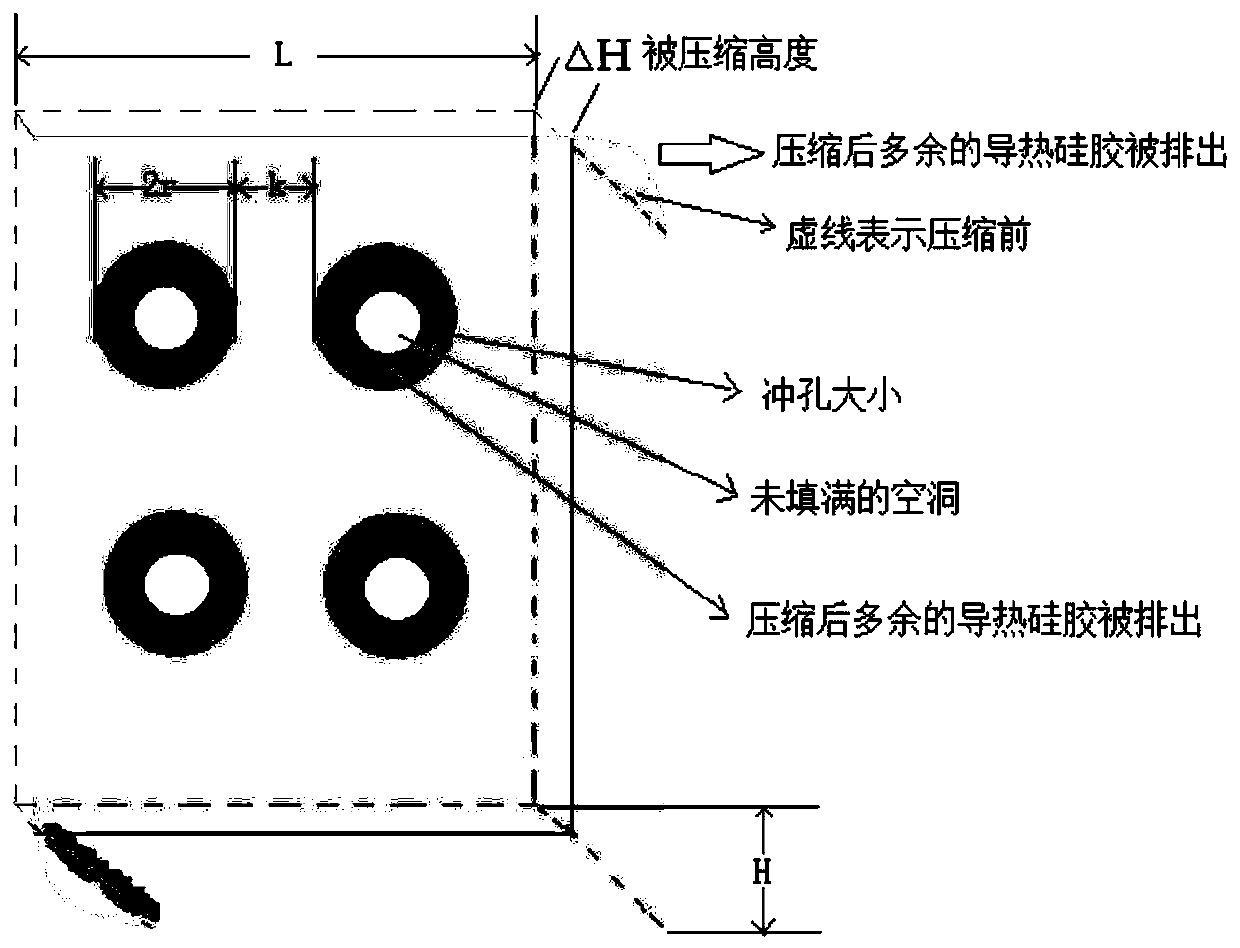

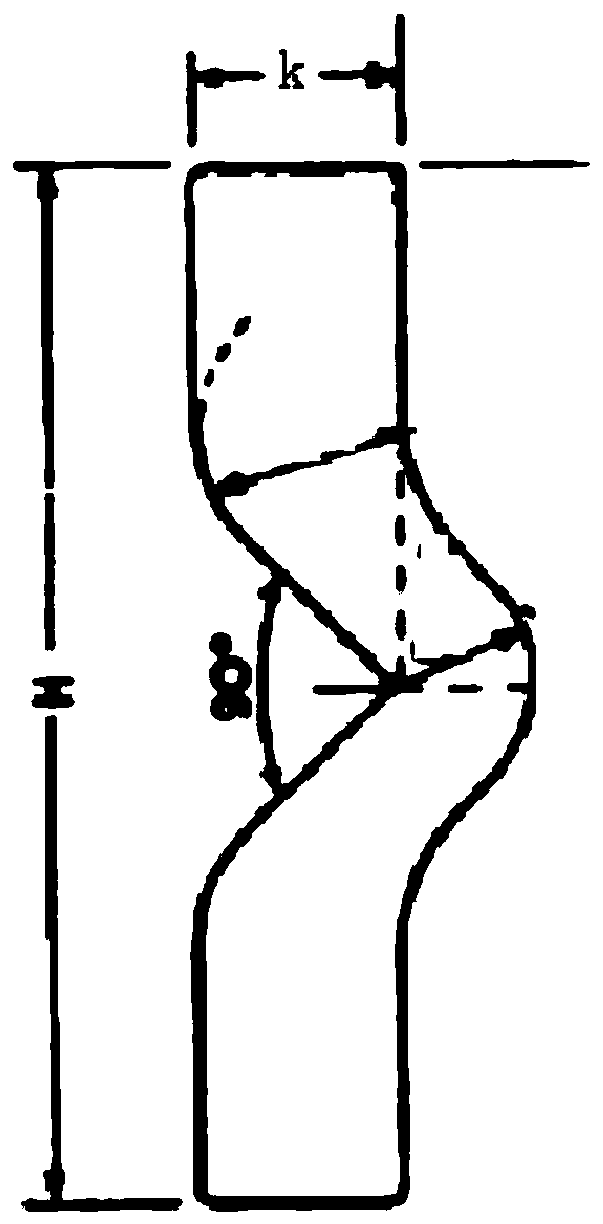

[0074] A heat-conducting silica gel sheet is prepared by the following method: a circular hole is punched out on the body of a heat-conducting silica gel sheet with a thickness of 30 mm and a thickness of 3 mm, and the radius of the circular hole is 12 mm.

Embodiment 2

[0076] A heat-conducting silica gel sheet is prepared by the following method: 2*2 round holes neatly arranged are punched out on a heat-conducting silica gel sheet body of 30*30mm and thickness of 3mm, and the radius of the round holes is 5.25mm.

Embodiment 3

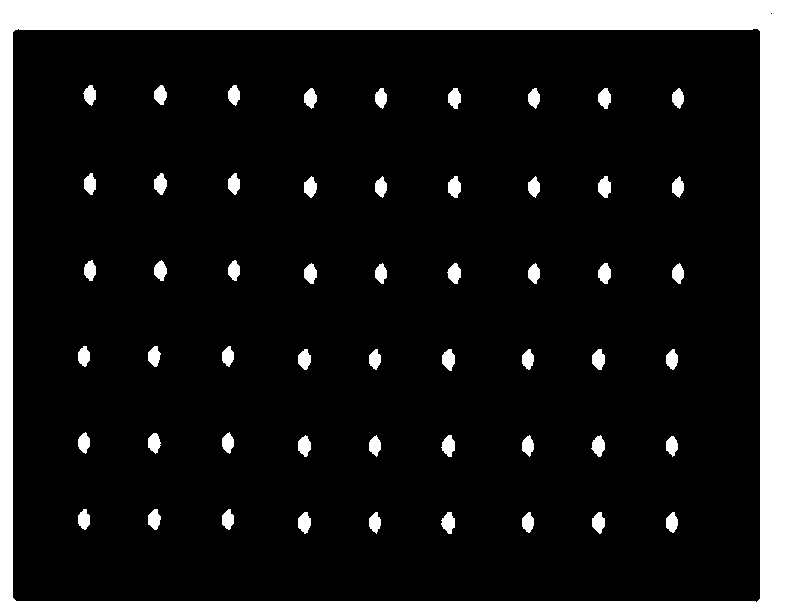

[0078] A heat-conducting silica gel sheet, which is prepared by the following method: 3*3 round holes neatly arranged are punched out on a heat-conducting silica gel sheet body of 30*30mm and thickness of 3mm, and the radius of the round holes is 3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com