Photovoltaic module frame

A photovoltaic module and frame technology, applied in the field of photovoltaic module frame, can solve the problems of increasing operation and maintenance cleaning costs, achieve the effects of increasing effective light receiving area, high reliability, reducing damage rate and transportation and packaging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

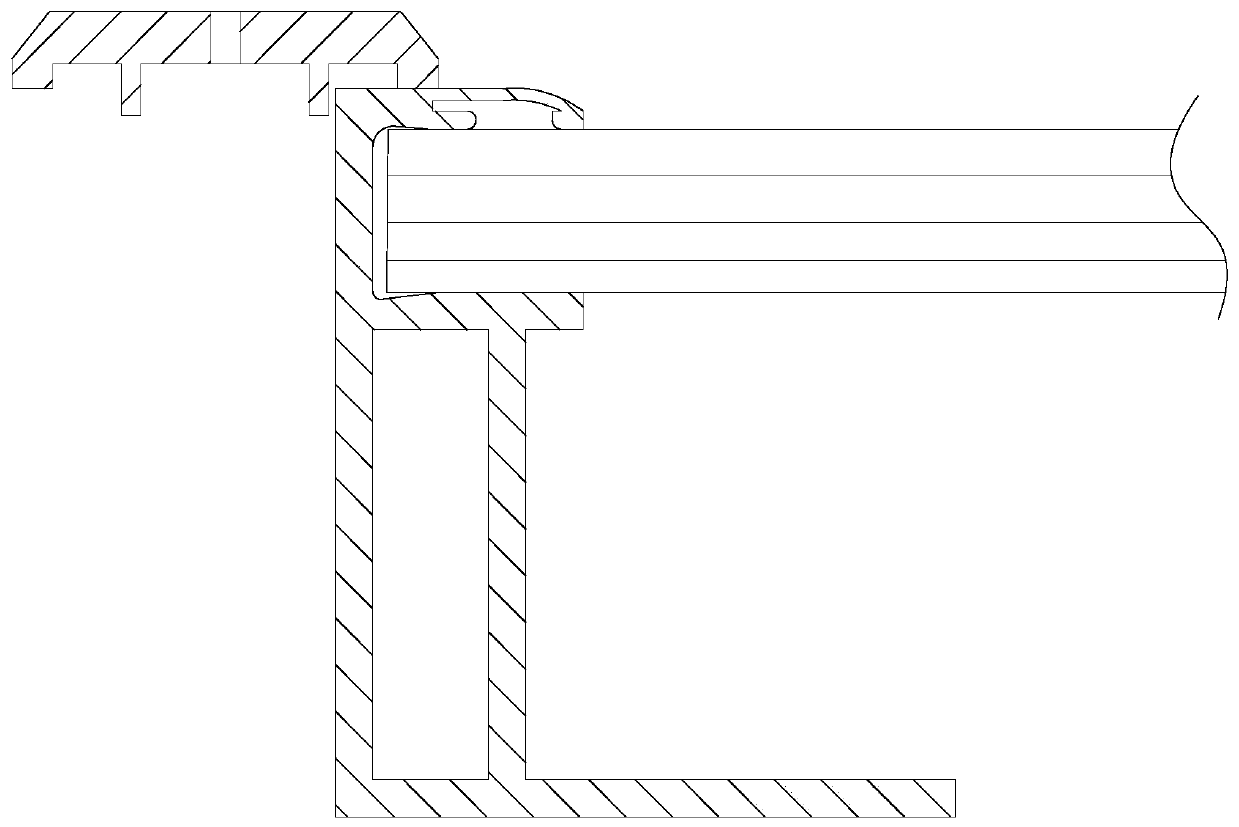

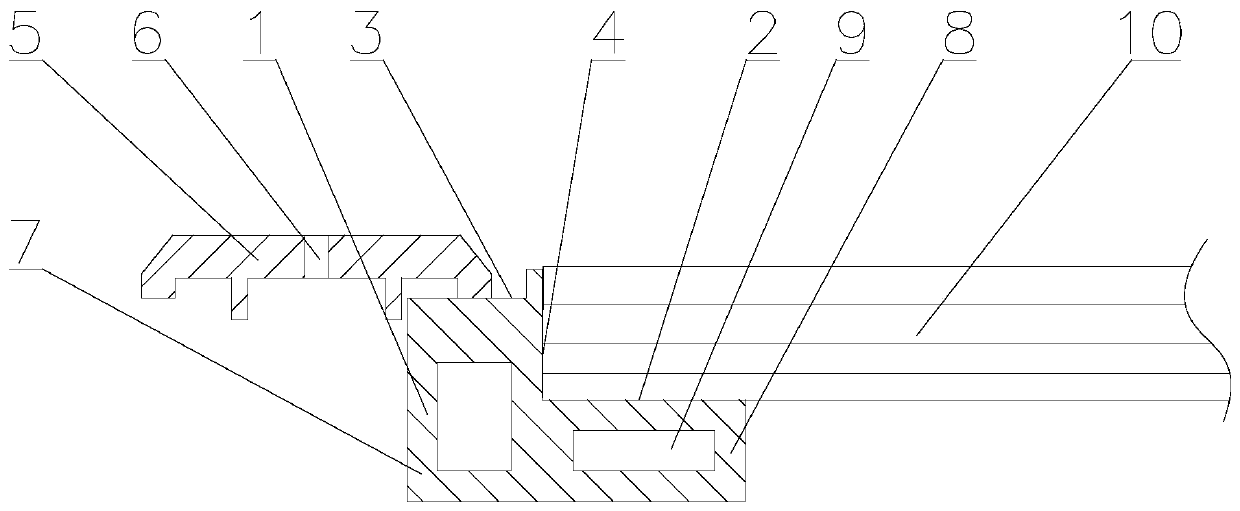

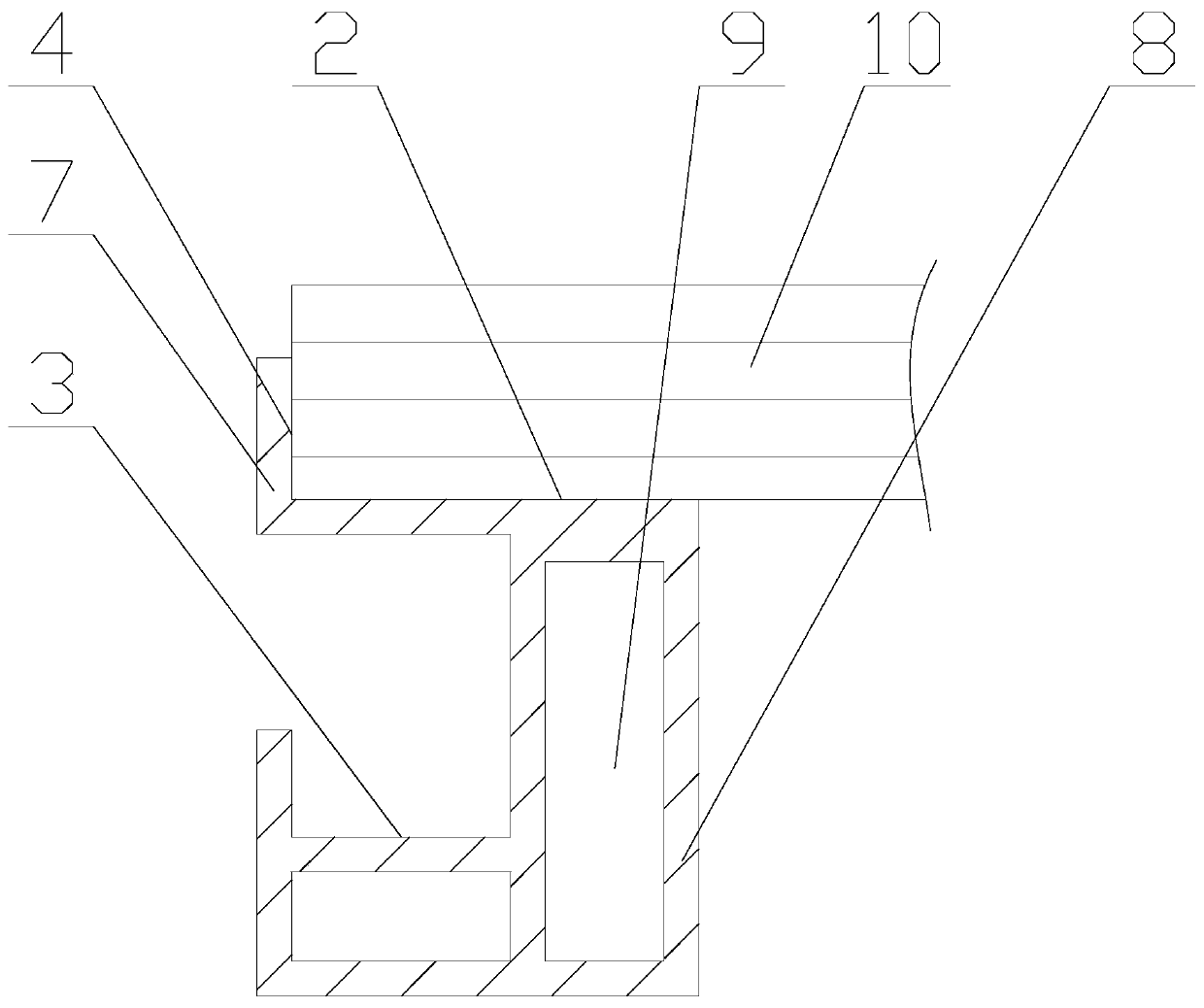

[0021] As shown in the figure, a photovoltaic module frame includes a supporting body 1, and the supporting body 1 is provided with a supporting bonding surface 2, a pressing surface 3 and a positioning surface 4; the supporting bonding surface 2 is located on the One side of the surface of the supporting body 1 is in contact with the bottom surface of the laminate of the photovoltaic module to support and bond the photovoltaic module; the positioning surface 4 is located on one side of the supporting bonding surface 2, and the The supporting adhesive surface 2 is perpendicular to the side of the photovoltaic module laminate; the press-fit surface 3 is located on one side of the positioning surface 4, and is used to connect with the pressure block 5 to fix the Support body 1.

[0022] Further, a press block 5 is provided on the press-fit surface 3, and the press block 5 is in contact with the press-fit surface 3 to press and install the entire frame structure of the photovolta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com