Foldable bus bar, circuit connection structure and imbricated assembly

A circuit connection and flow strip technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of difficulty in output power, large creepage distance occupied by the negative terminal circuit connection structure, and reduction of the effective light-receiving area of shingled components. Achieve the effect of reducing the area, improving the circuit connection, and increasing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

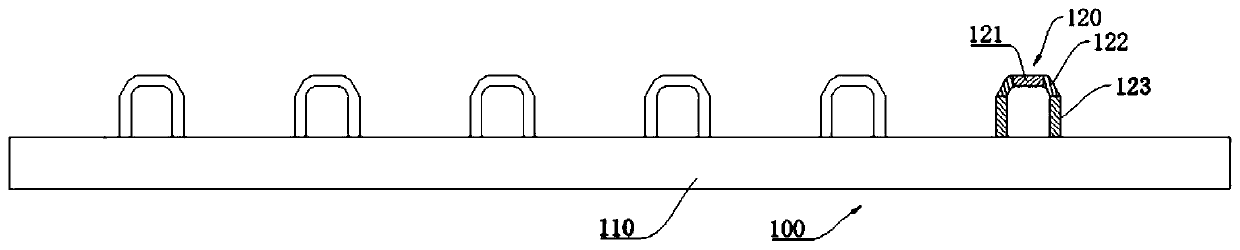

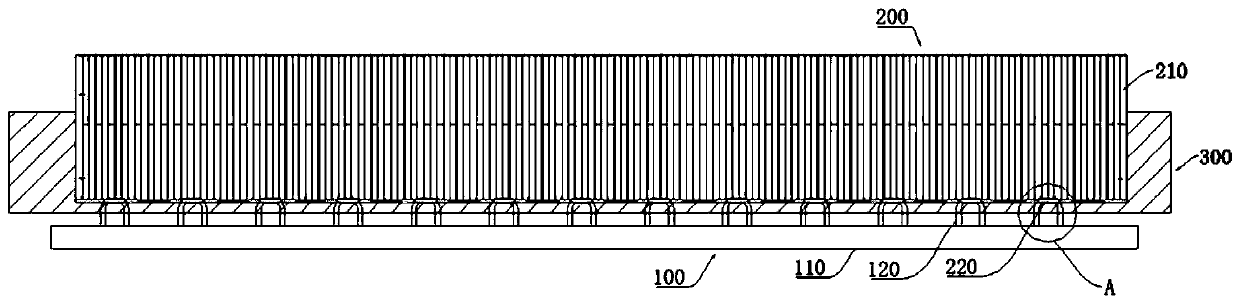

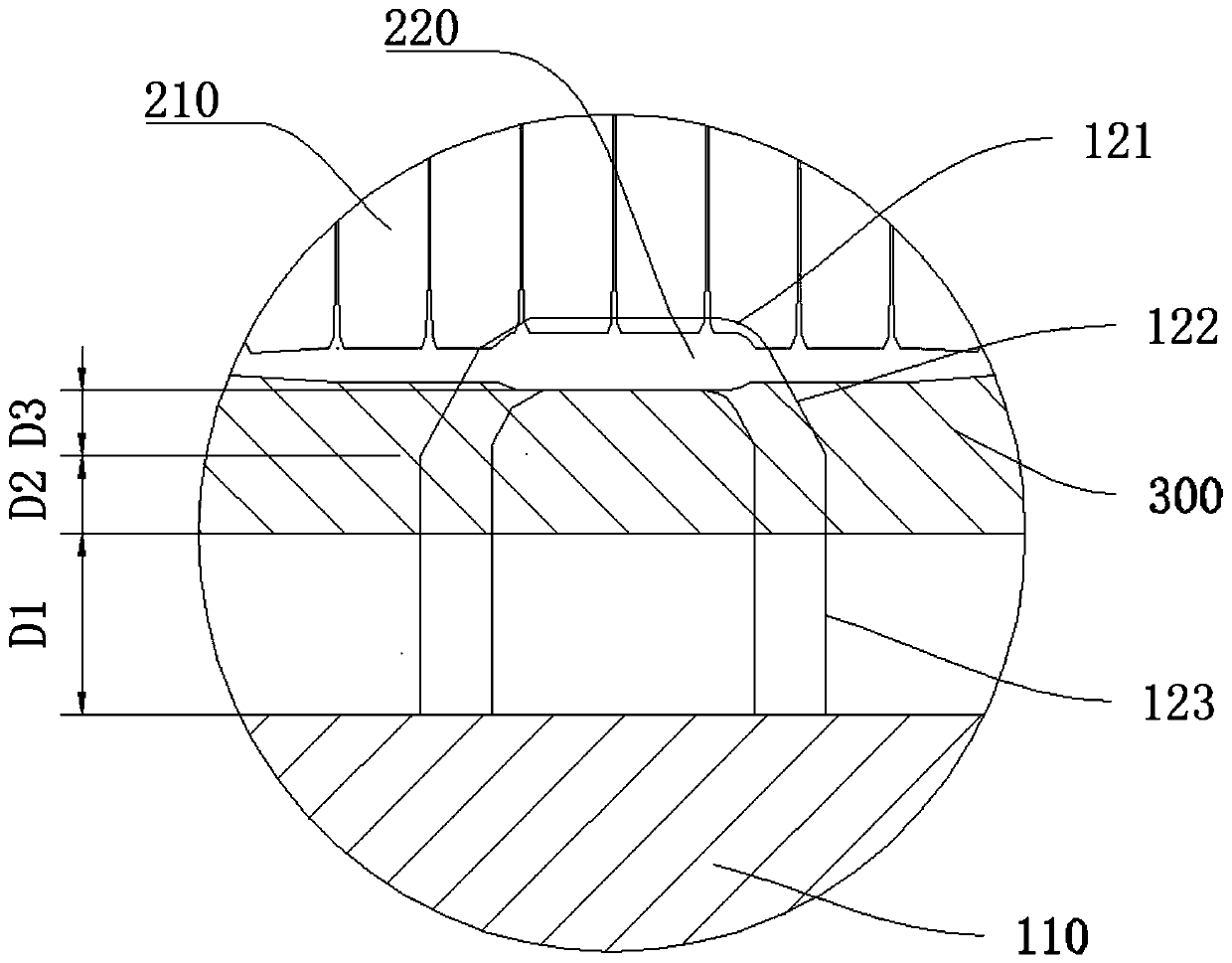

[0031] This embodiment proposes a foldable bus bar 100 for shingled components, such as figure 1 As shown, the main body 110 includes a rectangular structure, and there are several connection blocks 120 arranged side by side on one side of the main body 110. During the manufacturing process of the shingled assembly, the welding and matching structure diagram of the bus bar 100 and the battery sheet 200 is shown in figure 2 As shown, the connection block 120 is welded to the pad point 220 on the side of the front side 210 of the battery sheet 200 near the output end, and is folded together with the body 110 toward the back 230 of the battery sheet 200 along the edge of the side of the battery sheet 200 near the output end. . The foldable bus bar 100 in this embodiment can not only reduce the creepage distance occupied by the bus bar 100 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com