Double-row corn seeder pulled by mini-tiller by adopting auto-rotation and pit expanding principle

A technology of corn seeder and micro tillage machine, which is applied in the agricultural field, can solve the problems of not being able to guarantee the service life, the change of the depth of the pit, and the control of the depth of the pit, so as to improve the efficiency of breaking the soil, improve the efficiency of entry, and avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

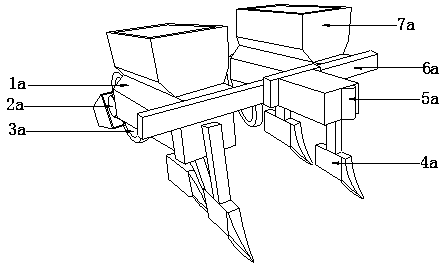

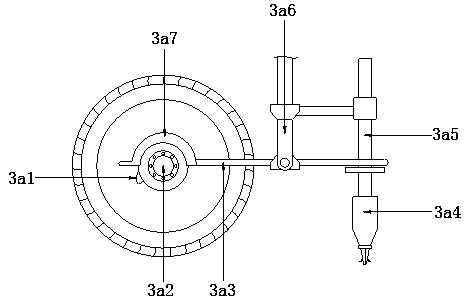

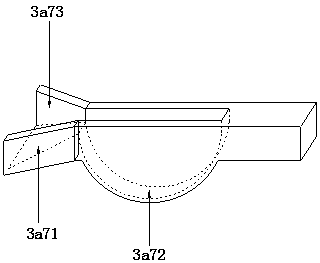

[0029] see Figure 1-Figure 6 , the present invention provides a kind of double-row corn planter towed by a tiller adopting the principle of self-rotation and hole expansion, its structure includes a quantitative distribution bin 1a, a chain shaft 2a, a moving wheel set 3a, a soil loosening shovel 4a, a traction arm 5a, Fix the crossbeam 6a and the material storage box 7a, the rear end of the traction arm 5a is installed on the middle part of the fixed crossbeam 6a by welding, and the two ends of the rear side of the fixed crossbeam 6a are respectively buckled and connected with the front end of the quantitative distribution bin 1a. The bottom of the feed box 7a is installed on the top of the quantitative distribution bin 1a by embedding, and the moving wheel set 3a is provided with two, and is respectively installed on the bottom of the rear end of the quantitative distribution bin 1a through a snap-fit mode, and the moving wheel set 3a The middle part is fitted and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com