A guiding and clamping mechanism for a syringe pump

A clamping mechanism and a technology for a syringe pump, applied in the field of syringe pumps, can solve the problems such as the inability to apply syringes of different specifications and the limitation of the use range of the syringe pump.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

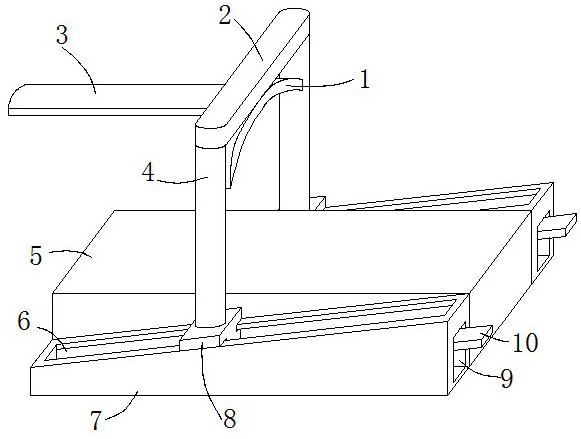

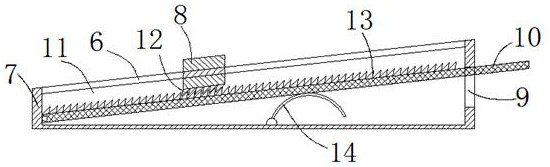

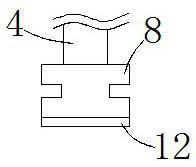

[0019] see Figure 1-3 , the present embodiment provides a guiding and clamping mechanism for an injection pump, comprising a mounting base 5 and two guiding bases 7, the guiding bases 7 are respectively fixed on the front and rear ends of the mounting base 5, and the top end surfaces of the two guiding bases 7 A 30-degree sliding slope is provided, and the left end is lower than the right end. The inner cavities of the two guide seats 7 are provided with a sliding cavity 11, and the top sliding slopes of the two guide seats 7 are provided with a sliding gap 6 communicating with the sliding cavity 11. The right end faces of the two guide seats 7 are all provided with a rectangular notch 9 communicating with the sliding cavity 11, and the inner cavities of the two sliding notches 6 are all slidably provided with an I-shaped slider 8, and the two I-shaped sliders 8 The bottom end faces are extended with locking teeth 12, and the left end faces of the inner chambers of the two sl...

Embodiment 2

[0023] see Figure 1-3 , further improvements have been made on the basis of Example 1:

[0024] The two I-shaped sliders 8 are respectively attached to the upper and lower side walls of the opening of the two sliding notches 6, and a freely rotatable steel ball is embedded in the joint position of the I-shaped slider 8 and the side walls of the opening of the sliding notch 6 , by arranging freely slidable steel balls, the friction force when the I-shaped slider 8 slides left and right can be reduced.

[0025] The bottom end surface of the arc-shaped positioning clamping plate 1 is extended with a plurality of evenly spaced convex points. By setting the convex points, it is convenient to clamp the side wall of the syringe and realize the positioning of the syringe.

[0026] The left end surface of the arc-shaped positioning clamp 1 is horizontally provided with an upwardly curved guide arc-shaped plate 3. By setting the guide arc-shaped plate 3, it is convenient to assist in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com