Pulverizer

A pulverizer and rack technology, used in wood processing appliances, grain processing, manufacturing tools, etc., can solve the problems of accidental interruption of pulverization, large differences in the shape of waste, and many crude fibers of waste, etc. Convenience of materials and the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

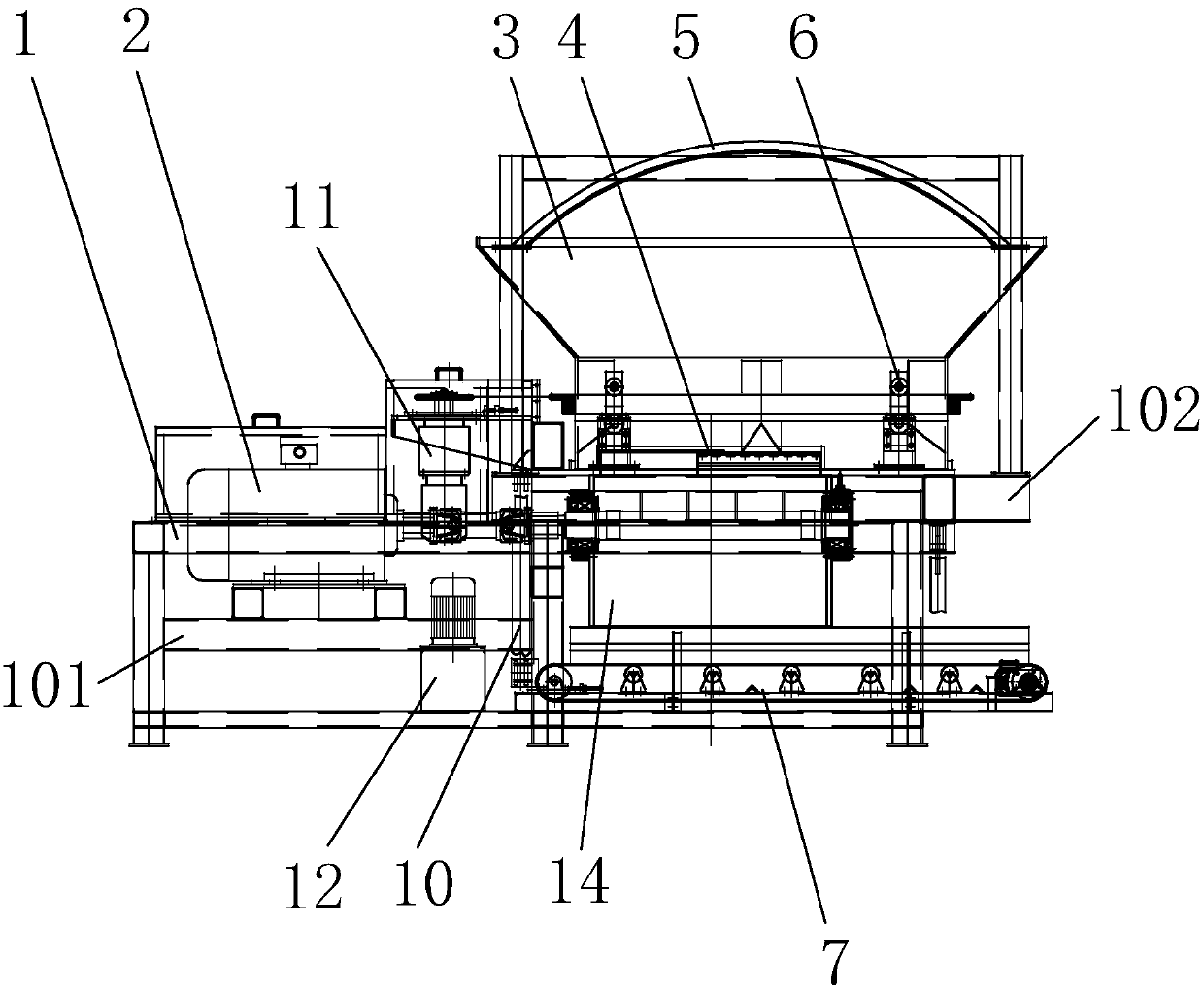

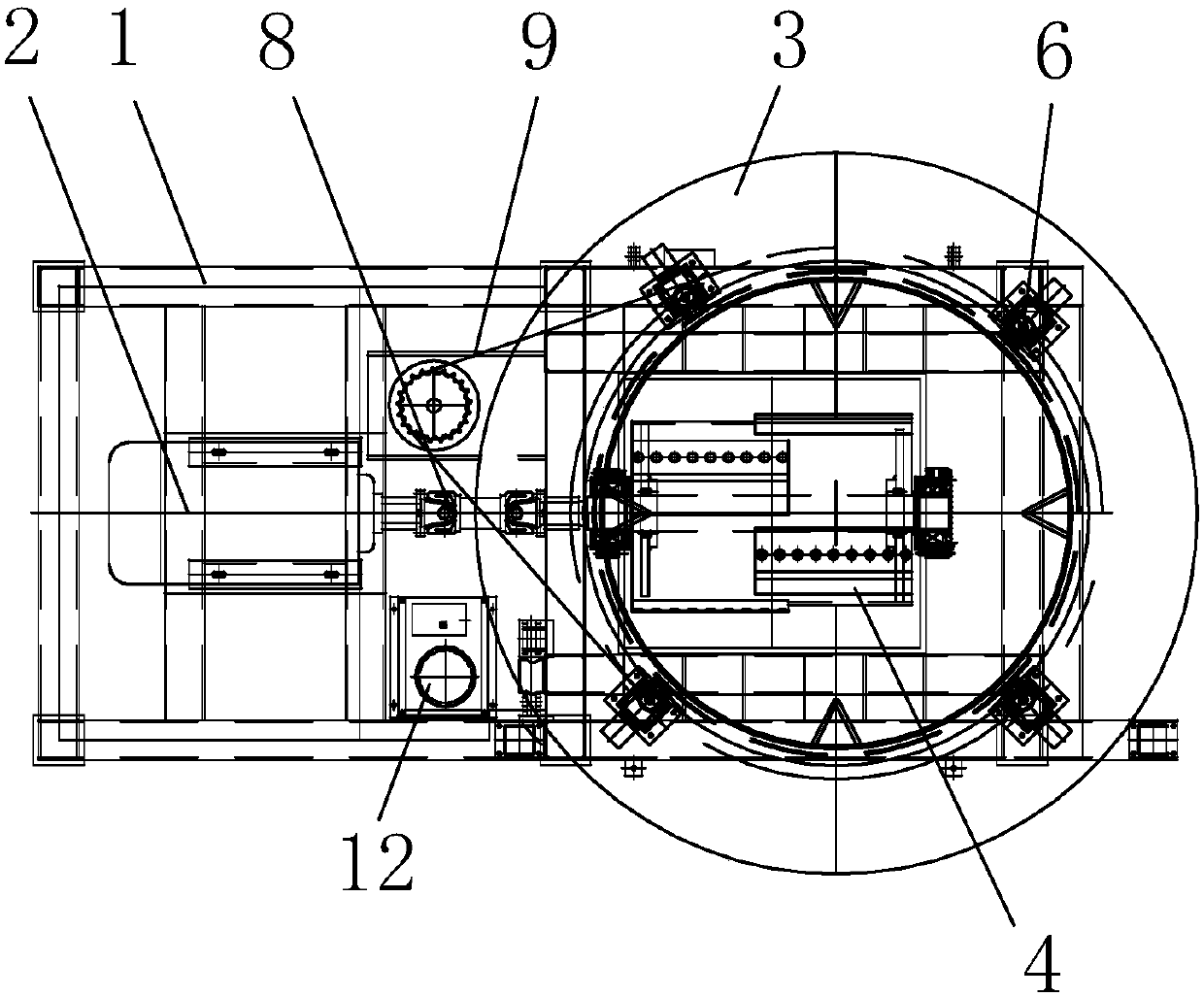

[0037] like Figures 1 to 3 As shown, a pulverizer includes a frame 1, a main deceleration motor 2, a feeding assembly 3, a knife roller assembly 4 and a deceleration auxiliary motor 11, wherein:

[0038] The aforementioned deceleration main motor 2 and deceleration auxiliary motor 11 are both installed on the frame 1;

[0039] The aforementioned deceleration main motor 2 drives the cutter roller assembly 4 to rotate through the coupling 8;

[0040] The aforementioned feeding assembly 3 is located above the knife roller assembly 4;

[0041] The aforementioned feeding assembly 3 includes a conical cylinder 301, a cylinder 302 and a feeding plate 303; the aforementioned conical cylinder 301 is fixed above the cylinder 302, and the inner side of the aforementioned cylinder 302 is fixedly connected to the feeding guide plate 303; the aforementioned conical cylinder 301 The cover 5 can be installed as required;

[0042] The aforementioned deceleration auxiliary motor 11 drives t...

Embodiment 2

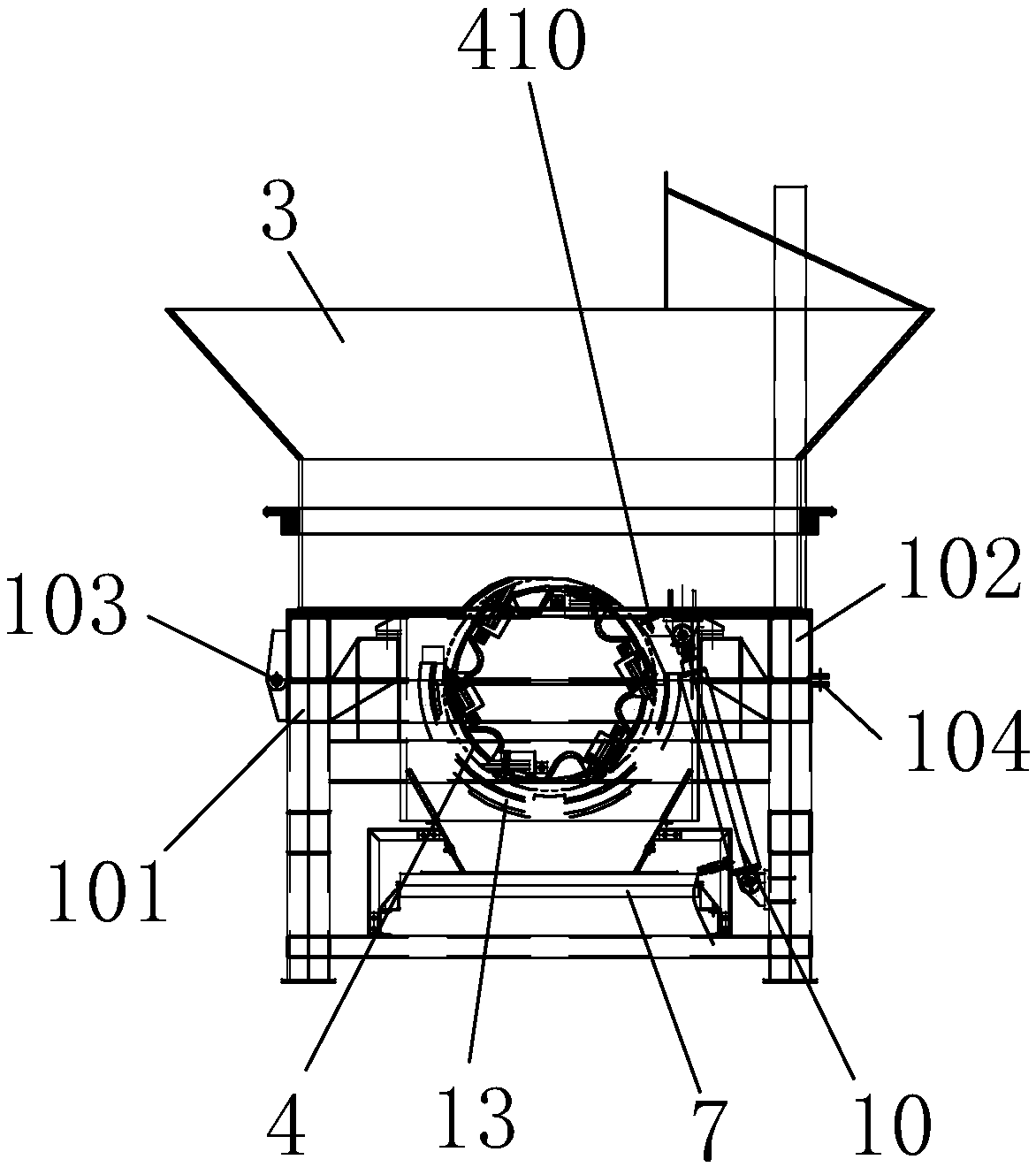

[0049] As an improvement of the first embodiment of the present invention, as Figures 1 to 3 and 12, the aforementioned rack 1 is composed of a lower rack 101 and an upper rack 102, wherein:

[0050] The aforementioned knife roller assembly 4 is installed on the lower frame 101, and the aforementioned blocking wheel assembly 6 is installed on the upper frame 102;

[0051] One end of the upper frame 101 and the lower frame 102 is positioned by the pin 103, the other end of the upper frame 101 and the lower frame 102 is connected by the hydraulic component 10, and the other end of the upper frame 101 and the lower frame 102 is also connected by the tightening. Firmware 104 is fixed;

[0052] The aforementioned lower frame 102 or the upper frame 101 is provided with a hydraulic oil pump 12 , and the aforementioned hydraulic oil pump 12 drives the hydraulic components 10 .

[0053] When adjustment is required, the fasteners 104 are loosened, the hydraulic oil pump drives the hy...

Embodiment 3

[0055] As an improvement of the first embodiment of the present invention, as Figures 4 to 7 As shown, the aforementioned blocking wheel assembly 6 includes a movable support 601, a middle seat 602 and a bottom plate 607, wherein:

[0056]The aforementioned movable support 601 and the middle seat 602 are fixedly connected, and the aforementioned middle seat 602 is fixed on the upper frame 101 through the bottom plate 607;

[0057] The movable support 601 is fixed with a 1# roller 605 , the middle seat 602 is fixed with a 2# roller 606 , and the blocking wheel 604 is fixed on the intermediate seat 602 through the blocking wheel mounting seat 603 .

[0058] The space formed by the blocking wheel 604 , the 1# roller 605 and the 2# roller 606 cooperates with and supports the sprocket 304 . Specifically, as Figure 4 , 7 As shown, the 2# roller 606 supports the lower surface of the sprocket, the 1# roller 605 confines the upper surface of the sprocket, and the stopper 604 confi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com