A kind of efficient hand-held spray gun and spraying method

A handheld, spray gun technology, applied in the direction of spray device, liquid spray device, etc., can solve the problems of heavy spray gun and loud noise, and achieve the effect of eliminating dripping phenomenon, reducing pollution and good spraying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

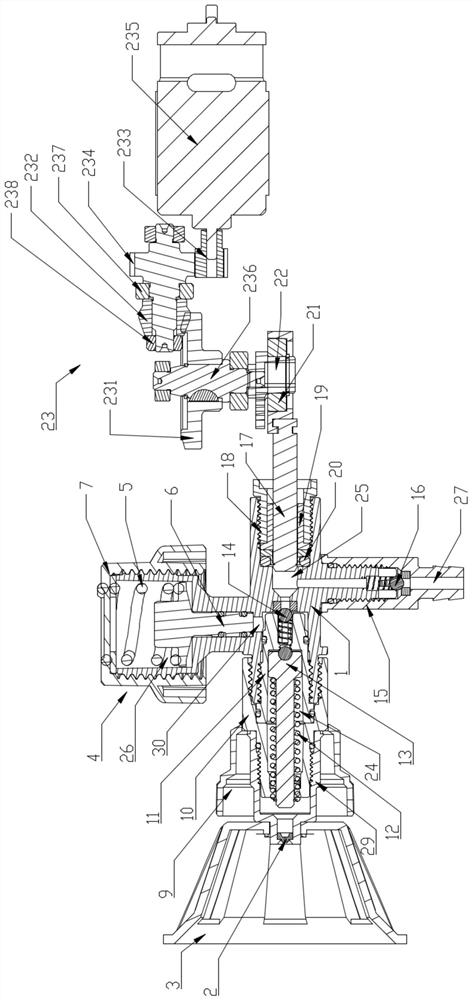

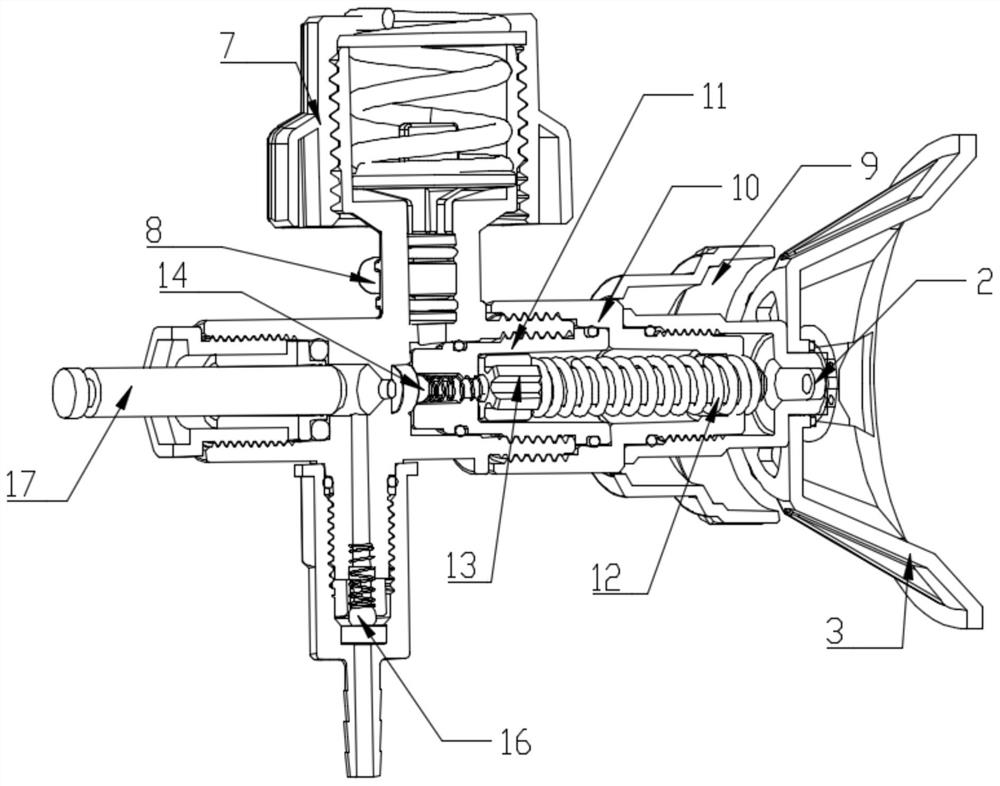

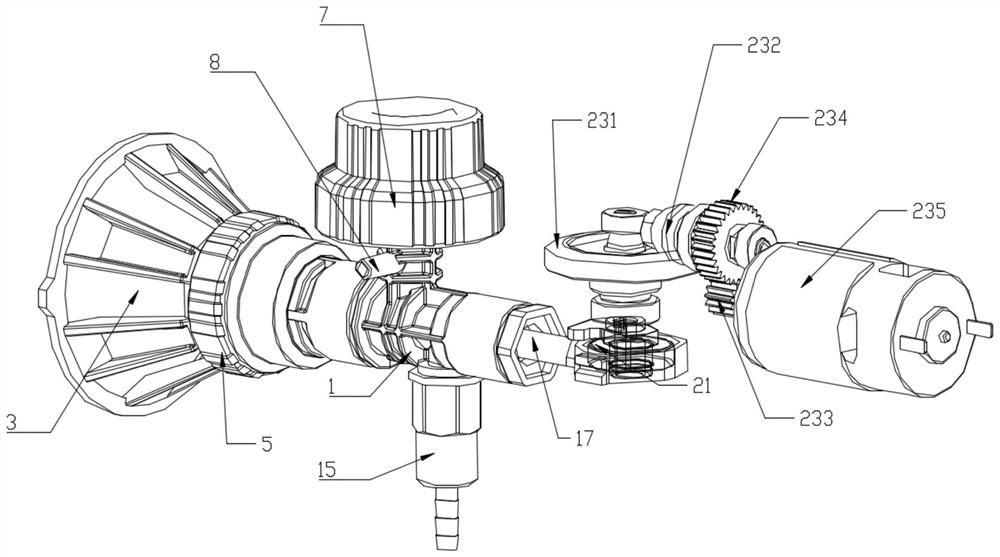

[0048] This embodiment discloses a high-efficiency spray gun, such as Figure 1-2 As shown, including the pump body 1 and the nozzle 2, the pump body is provided with a liquid outlet chamber 24. There is a voltage stabilizer 4 on the top, and the position of the voltage stabilizer 4 is connected with the liquid outlet chamber 24; the voltage stabilizer 4 is used to maintain a stable spraying pressure for the spray liquid in the liquid outlet chamber to ensure that the nozzle The spray liquid is continuously sprayed.

[0049] Concretely, the voltage stabilizer 4 is arranged in the pressure stabilizing chamber 26 on the pump body 1, and the stabilizing chamber 26 is communicated with the liquid outlet chamber 24, and the position change of the pressurized pressure stabilizer controls the connection with the liquid outlet chamber. The size of the liquid storage space can be adjusted according to the size of the hydraulic pressure when the spraying liquid is filled into the liqui...

Embodiment 2

[0084] The difference from Embodiment 1 is that the voltage stabilizer 4 of this embodiment is a pressure-deformable member, such as an elastic block or an air bag, which limits one end of the elastic block or air bag to the limit portion 31 at the bottom of the pressure stabilizing chamber 26 The liquid inlet 30 between the liquid outlet chamber 24 and the pressure stabilizing chamber 26 is blocked, and the other end is connected with the regulating member 7 .

[0085] The liquid storage space 28 is enlarged by the deformation of the elastic block or the air bag under pressure, so that too much liquid in the liquid outlet cavity enters the liquid storage space. When the preset pressure value is exceeded, the deformation reaches the maximum, and the return hole is exposed, and the spraying liquid flows back. into the storage bag.

Embodiment 3

[0087] Corresponding to the aforementioned high-efficiency hand-held spray gun, the present invention also provides a method for constant pressure spraying, comprising the following steps:

[0088] The S1 spray gun starts to absorb liquid, sucks the spraying liquid into the liquid outlet chamber, the nozzle does not discharge liquid, and the voltage stabilizer in the pressure stabilization chamber blocks the connection port in the pressure stabilization chamber and the liquid outlet chamber;

[0089] S2 After the outlet chamber is full of spraying liquid, continue to feed the liquid so that the spraying liquid squeezes the regulator to form a pressure that drives the regulator to move and open the connection port, and the spraying liquid enters the liquid storage space in the regulator chamber and the outlet chamber. , the spraying liquid is sprayed from the nozzle on one side of the liquid outlet chamber, and the voltage stabilizer generates a stable pressure on the spraying l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com