A high-precision positioning tool compensation device for workpiece machining

A tool compensation and high-precision technology, applied in the field of tool compensation devices, can solve problems such as poor universality of compensation devices, contamination of machining debris, damage to sensors, etc., and achieve the effects of ensuring accuracy, ensuring cleanliness, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

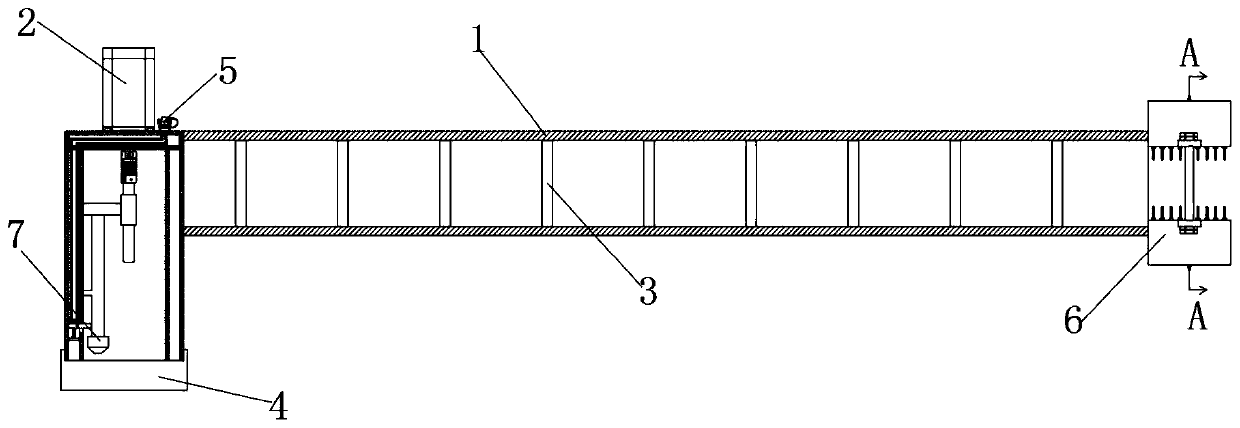

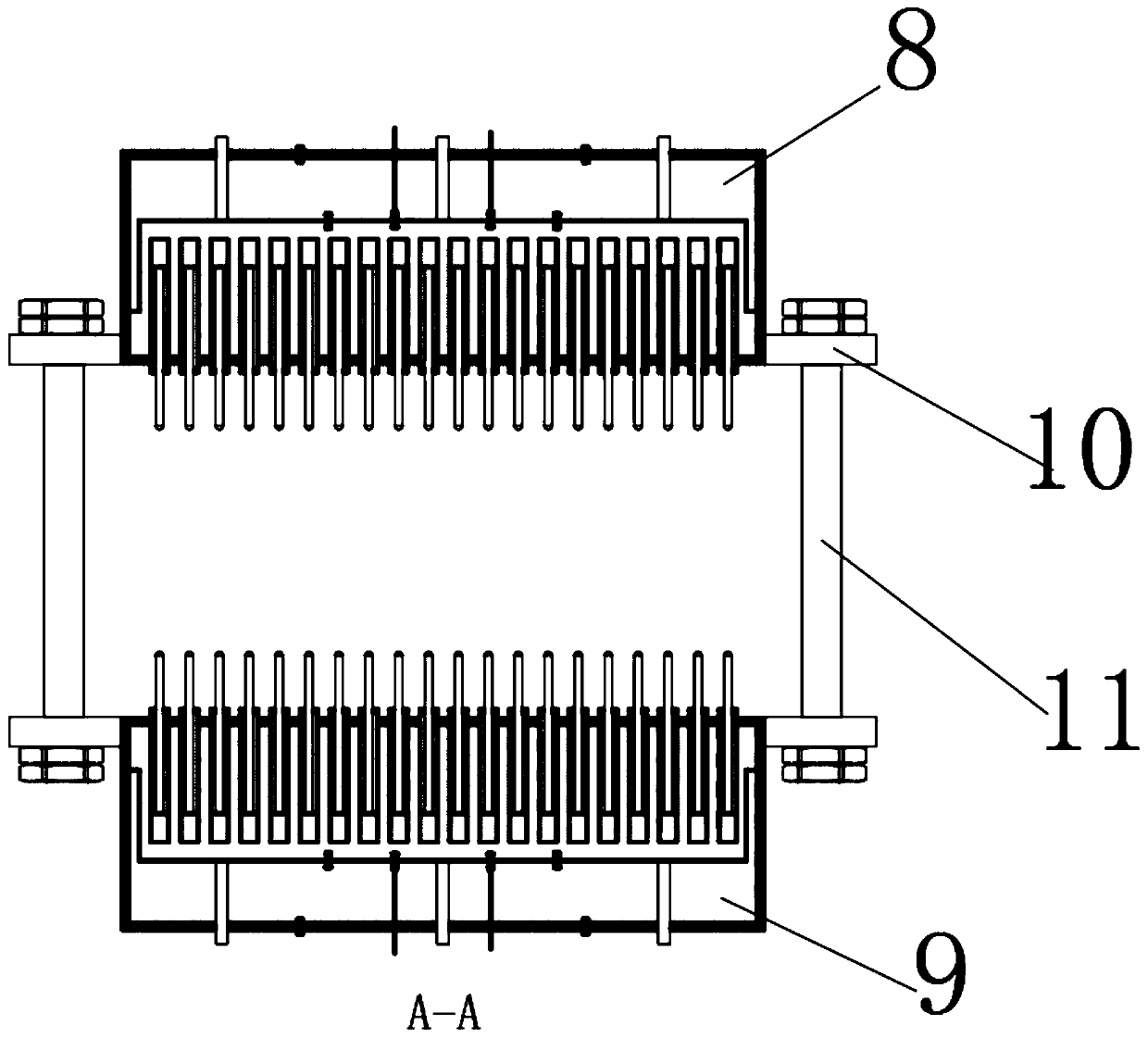

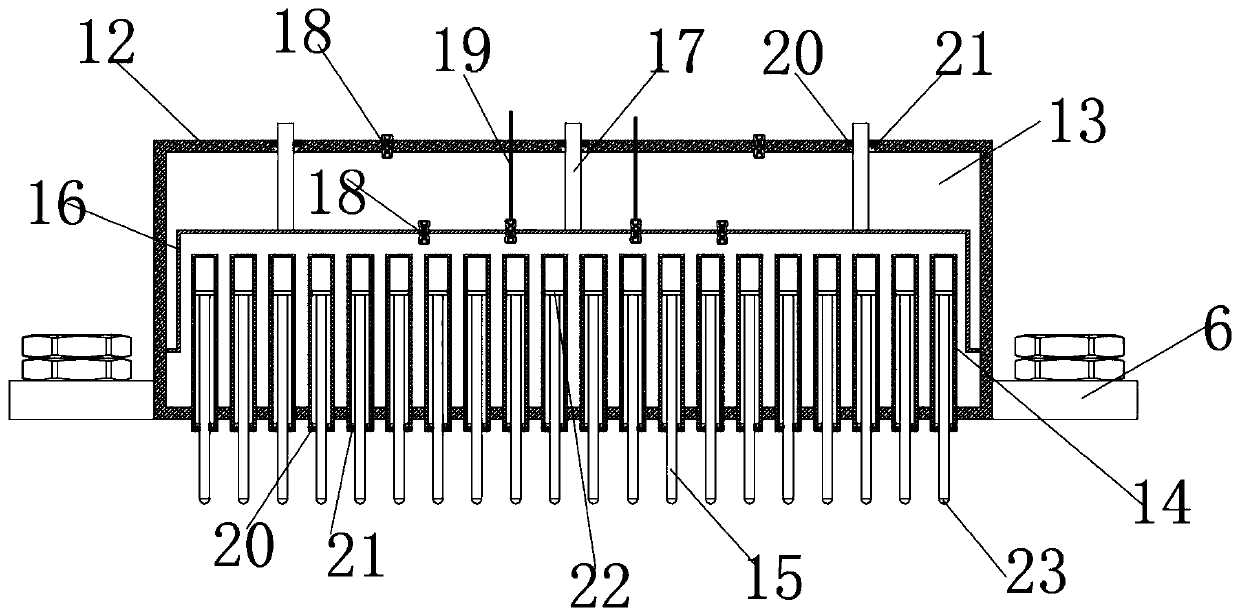

[0025] Example: see Figure 1-6 , the present invention provides a technical solution: a high-precision positioning tool compensation device for workpiece processing, which includes a base 1, one end of the base 1 is connected to a detection component, and the other end is connected to a fixed component 6, the detection The assembly is used to detect the position of the tool and feed it back to the control center to adjust the tool. The fixed assembly 6 is used to fix the base 1 and the detection assembly on the processing device. The fixed assembly 6 is fixed on the processing machine tool. Initially, the detection The component detects the position of the tool and feeds it back to the control center. After a period of processing, it detects the position of the tool again and feeds it back to the control center. The control center compares the two sets of data and adjusts the position of the tool. It should be noted that the machine tool It has the ability to adjust in X, Y a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com