Flash removing punch die and flash removing method for plastic package belt of chip tantalum capacitor

A chip-type tantalum capacitor technology, which is used in the field of flash removal dies and flash removal for chip tantalum capacitors. Unclean and other problems, to achieve the effect of not easy to deform the strip, reduce labor intensity, and have good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

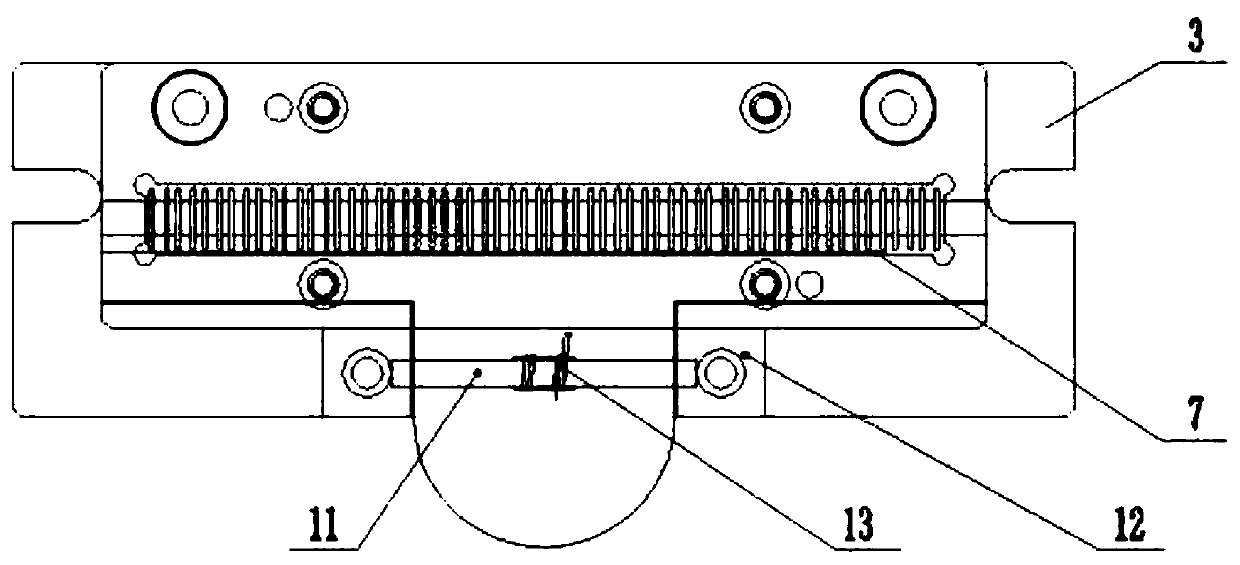

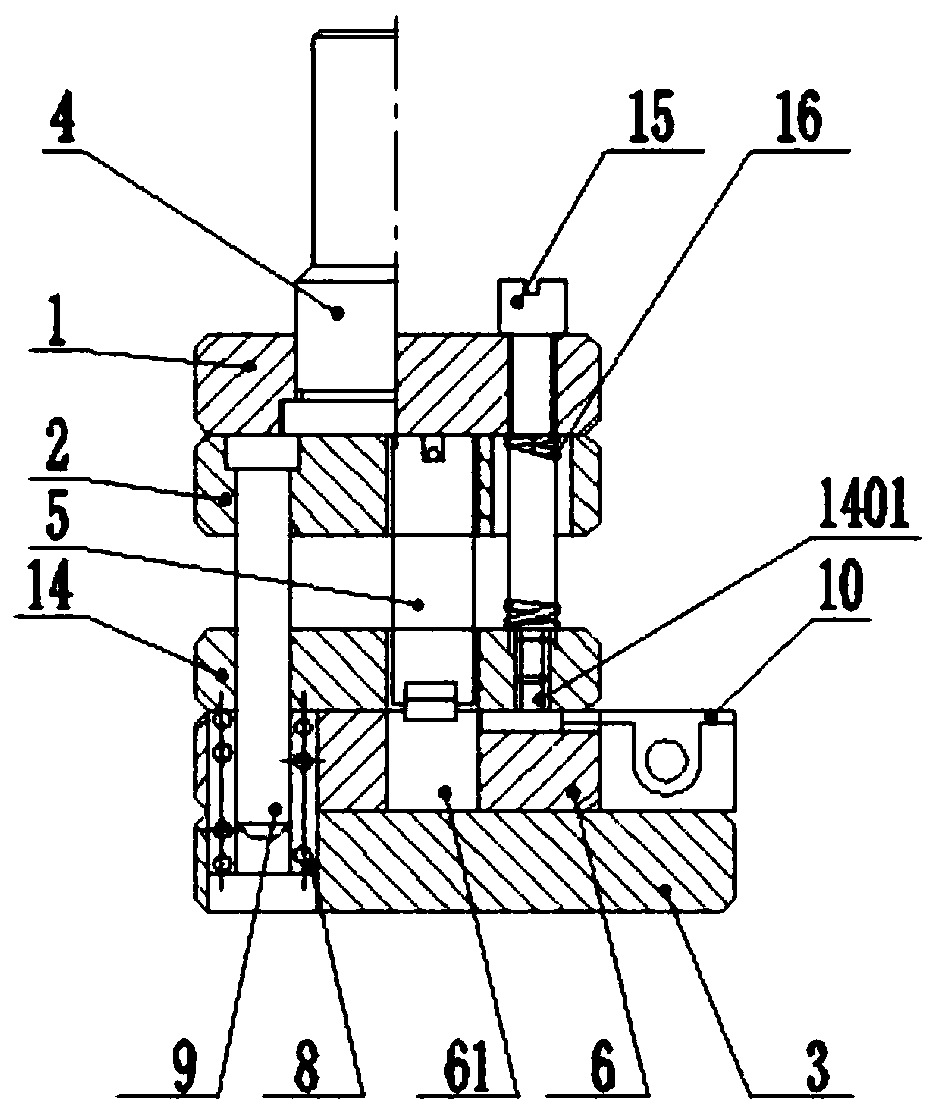

[0022] The present invention provides a chip type tantalum capacitor plastic seal tape overflow removal punching die, such as figure 1 , figure 2 As shown, it includes an upper template 1, a lower template 2 and a base 3. The upper template 1 and the lower template 2 are overlapped and fixedly connected together. The upper template 1 is fixedly connected with a punch handle 4, and the upper template 2 is fixedly connected. There is a convex mold 5, and a concave mold 6 is fixedly connected on the base 3, and a mold hole 61 is arranged on the concave mold 6, and the convex mold 5 can fit in the mold hole 61. The punch handle 4 is conveniently connected with corresponding power devices such as stamping equipment, and by using automatic equipment instead of manually scraping off the overflow, labor costs and labor intensity are redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com