Slicing device for manufacturing silicon rod of solar photovoltaic panel

A solar photovoltaic panel and slicing device technology, which is applied in the field of solar photovoltaic panel accessories, can solve the problems of uneven slice thickness of silicon rods, dependence on labor, single fixation, etc., and achieve the effect of saving manpower and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

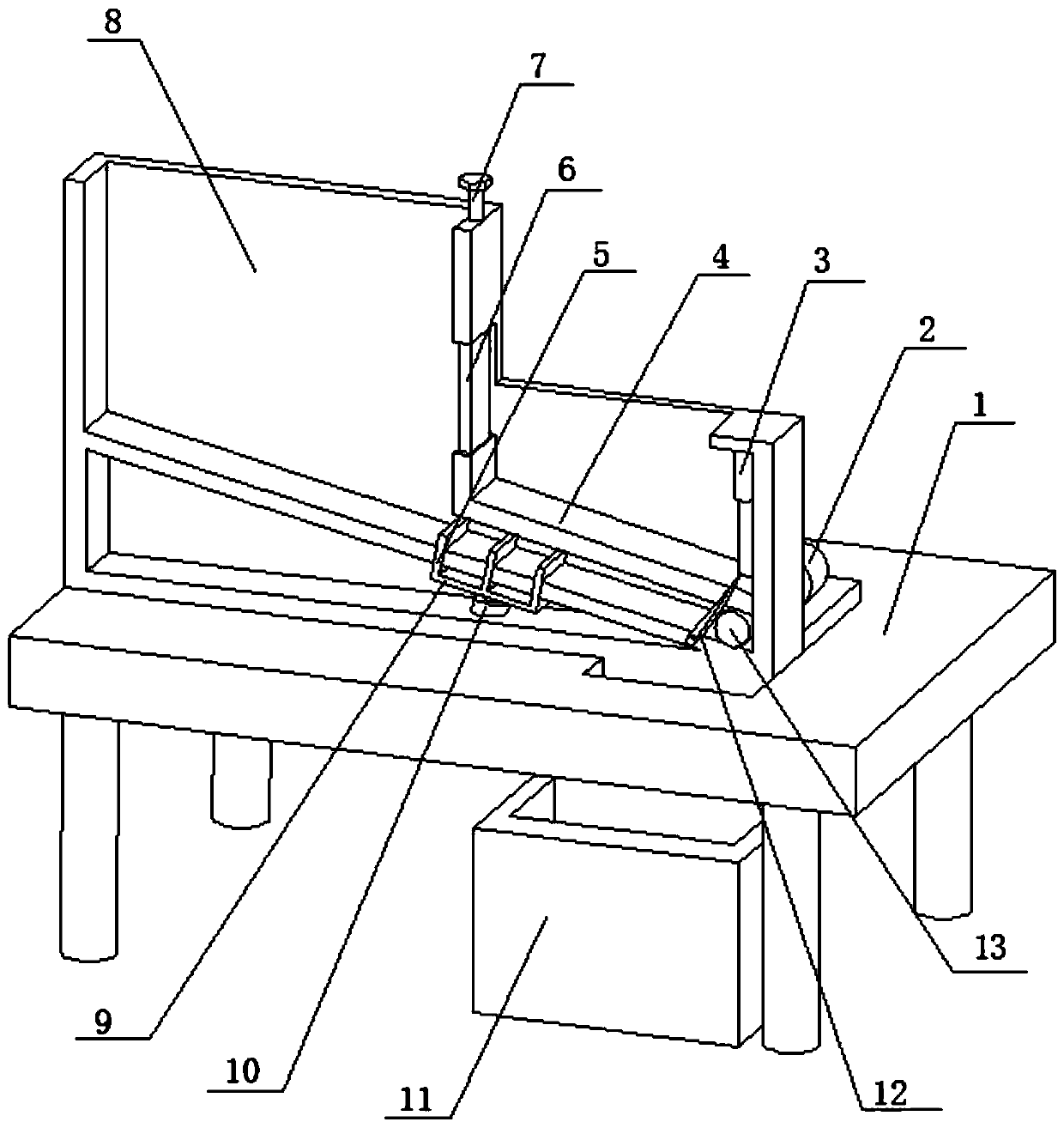

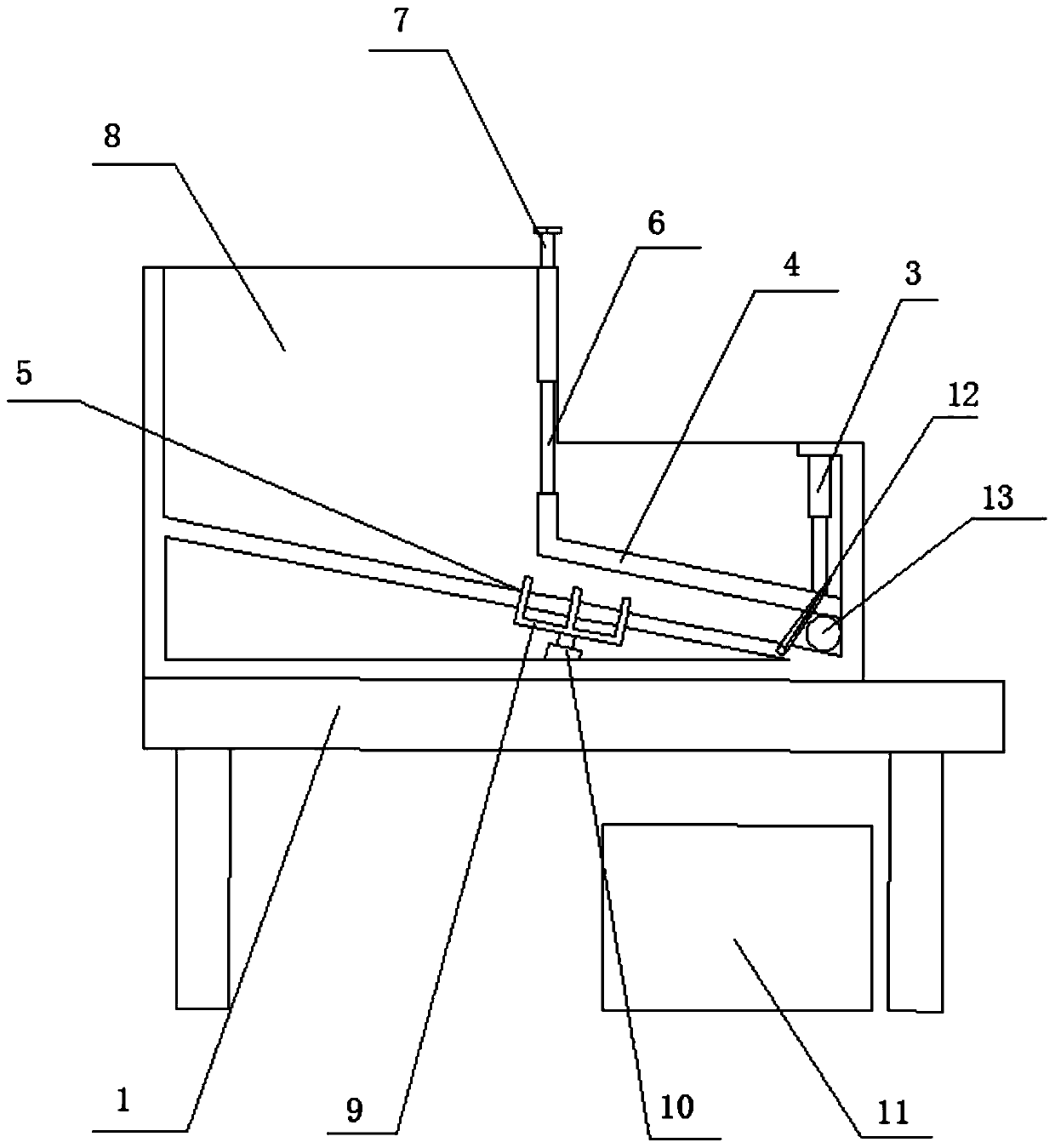

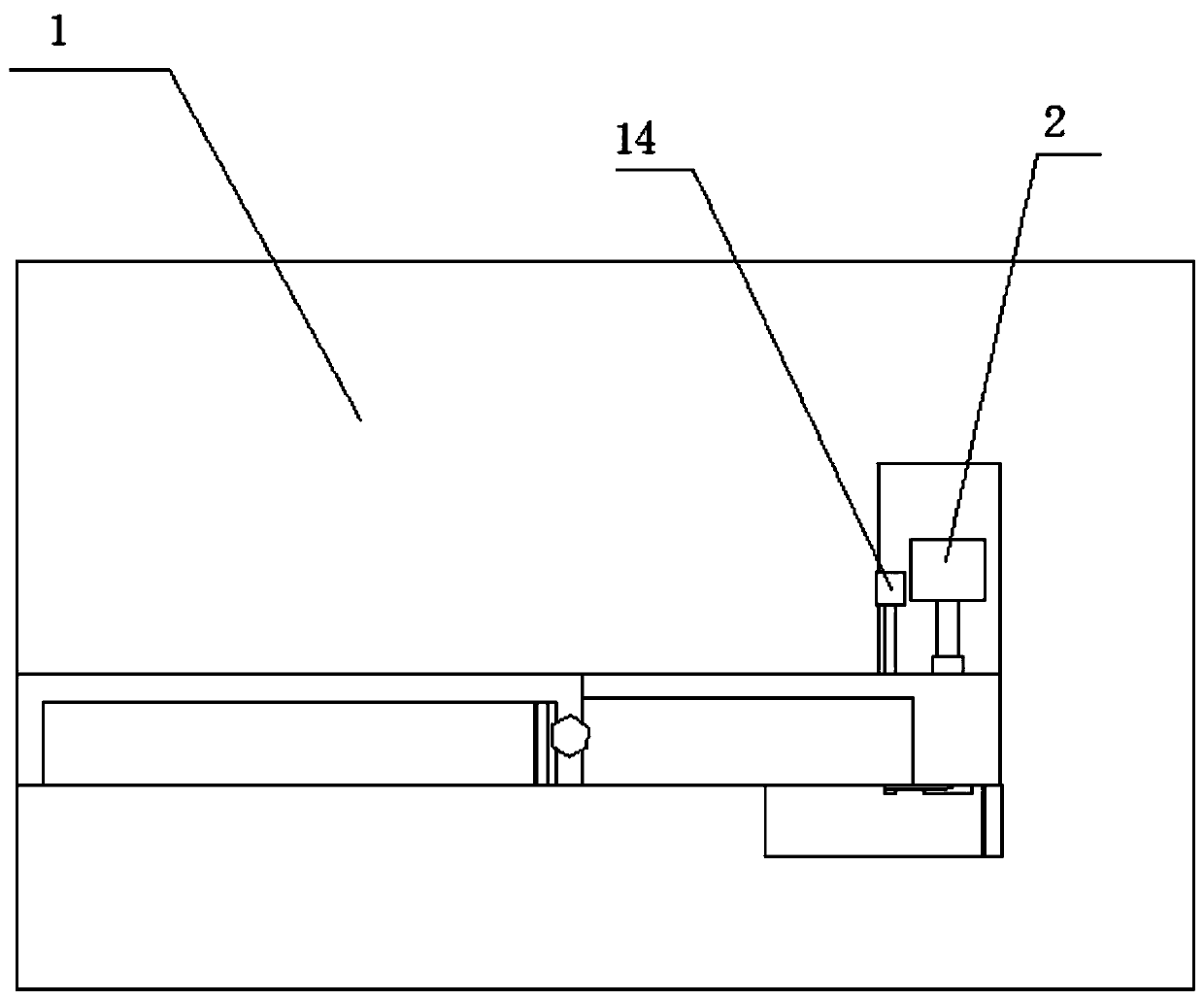

[0014] refer to Figure 1 to Figure 3 The embodiment of the invention of a slicing device for silicon rods used for making solar photovoltaic panels will be further described.

[0015] A silicon rod slicing device for making solar photovoltaic panels, comprising a workbench 1, a hopper 8 is provided on the workbench 1, the bottom surface of the hopper 8 is inclined, and the side wall of the hopper 8 is provided with Opening, the top wall of the opening is provided with a receiving groove, and a sliding plate 6 is slid in the receiving groove, and the top of the sliding plate 6 is rotatably connected with a bolt 7, and the bolt 7 is threadedly connected with the side wall of the hopper 8 and extends The top of the discharge hopper 8, the bottom of the slide plate 6 is connected with a guide plate 4, the inclination direction of the guide plate 4 is consistent with the inclination direction of the bottom surface of the hopper 8, the guide plate 4 and the bottom surface of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com