Purifying method for hydrogen bromide

A purification method and hydrogen bromide technology, which is applied in the field of hydrogen bromide purification, can solve the problems of pure nickel corrosion, large equipment investment, and potential safety hazards, and achieve the effects of ensuring product quality, reducing equipment investment, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in conjunction with accompanying drawing and embodiment:

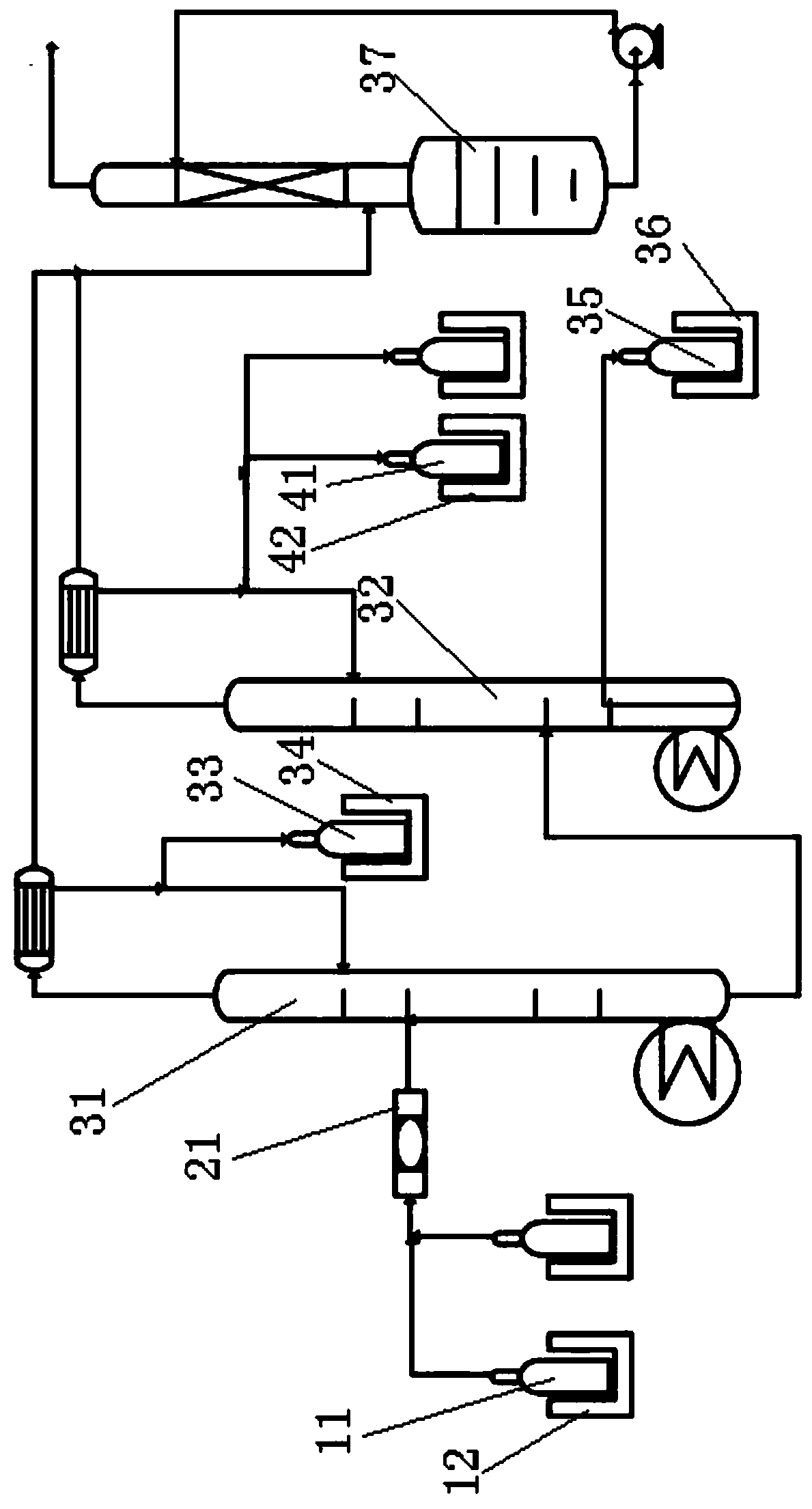

[0031] see figure 1 , as shown in the legend therein, a hydrogen bromide purification plant comprising:

[0032] The raw material supply unit comprises two hydrogen bromide raw material steel cylinders 11, and the outside of each hydrogen bromide raw material steel cylinder 11 is provided with a heating blanket 12;

[0033] Drying unit, it comprises Nafion drier 21, the inlet of Nafion drier 21 is connected with the outlet of hydrogen bromide raw material steel cylinder 11, desiccant uses polytetrafluoroethylene (Teflon) and perfluorinated-3,6-diepoxy - a copolymer of 4-methyl-7-decene-sulfuric acid;

[0034] Rectification unit, it comprises delightening rectification tower 31 and weight-removing rectification tower 32, the middle and upper part inlet of light-removing rectification tower 31 is connected with the outlet of Nafion drier 21, the weight-removing rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com