Method for improving burning grey of low-quantification cigarette paper and cigarette ash wrapping effect

A cigarette paper, low quantitative technology, applied in the direction of paper, tobacco, papermaking, etc., to achieve the effect of not easy to fall, easy to purchase, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

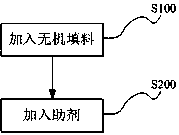

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1: prepare 25 g / m 2 machine rolling paper

[0060] Inorganic filler: The amount of inorganic filler added is 38% of the absolute dry weight of the paper, and the weight ratio of light calcium carbonate and magnesium hydroxide is 20:1.2;

[0061] Auxiliaries: The amount of additives added is 2.7% of the absolute dry weight of the paper. The combustion aids are potassium citrate and sodium citrate, and the auxiliaries are sodium pyrophosphate and disodium hydrogen phosphate. Potassium citrate: sodium citrate: pyrophosphate The weight ratio of sodium: sodium dihydrogen phosphate is 1:3:2:0.5, and potassium oxalate accounts for 0.5% of the total weight of the combustion aid.

Embodiment 2

[0062] Embodiment 2: prepare 20 g / m 2 rolling paper

[0063] Inorganic filler: The amount of inorganic filler added is 25% of the absolute dry weight of the paper, and the weight ratio of light calcium carbonate and magnesium hydroxide is 20:1;

[0064] Auxiliaries: The amount of additives added is 2% of the absolute dry weight of the paper. The combustion aids are potassium malate and sodium malate, and the auxiliaries are sodium pyrophosphate and sodium polyphosphate. Potassium malate: sodium malate: sodium pyrophosphate : The weight ratio of sodium polyphosphate is 1:3:2:1, and potassium oxalate accounts for 0.3% of the total weight of the combustion aid.

Embodiment 3

[0065] Example 3: Preparation of 13 g / m 2 rolling paper

[0066] Inorganic filler: The amount of inorganic filler added is 20% of the absolute dry weight of the paper, and the weight ratio of light calcium carbonate and magnesium hydroxide is 20:1;

[0067] Auxiliaries: The amount of additives added is 1% of the absolute dry weight of the paper, the combustion aid is sodium citrate, the auxiliaries are sodium pyrophosphate and ammonium dihydrogen phosphate, the weight of sodium citrate, sodium pyrophosphate and ammonium dihydrogen phosphate The ratio is 0.5:1:1, and potassium oxalate accounts for 0.2% of the total weight of the combustion accelerant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap