Faucet valve core with water mixing and distributing functions

A faucet and water mixing valve technology, applied in the field of faucet valve core, can solve the problems of small inner ring knob area, unfavorable operation, unfavorable processing faucet installation, affecting water inlet and outlet efficiency, etc., to optimize the water outlet setting method and reduce the water connection requirements. , The effect of easy mixing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

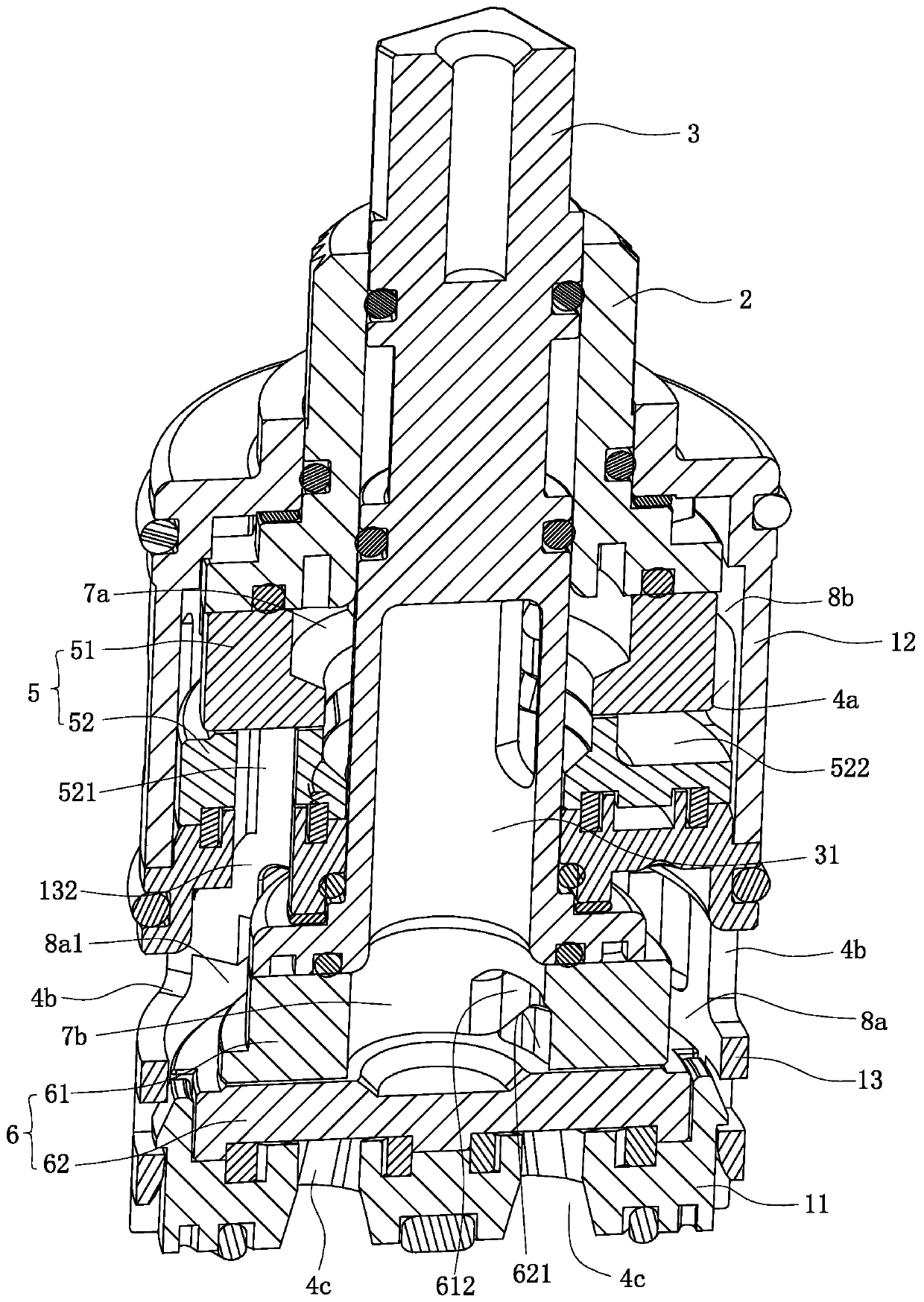

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

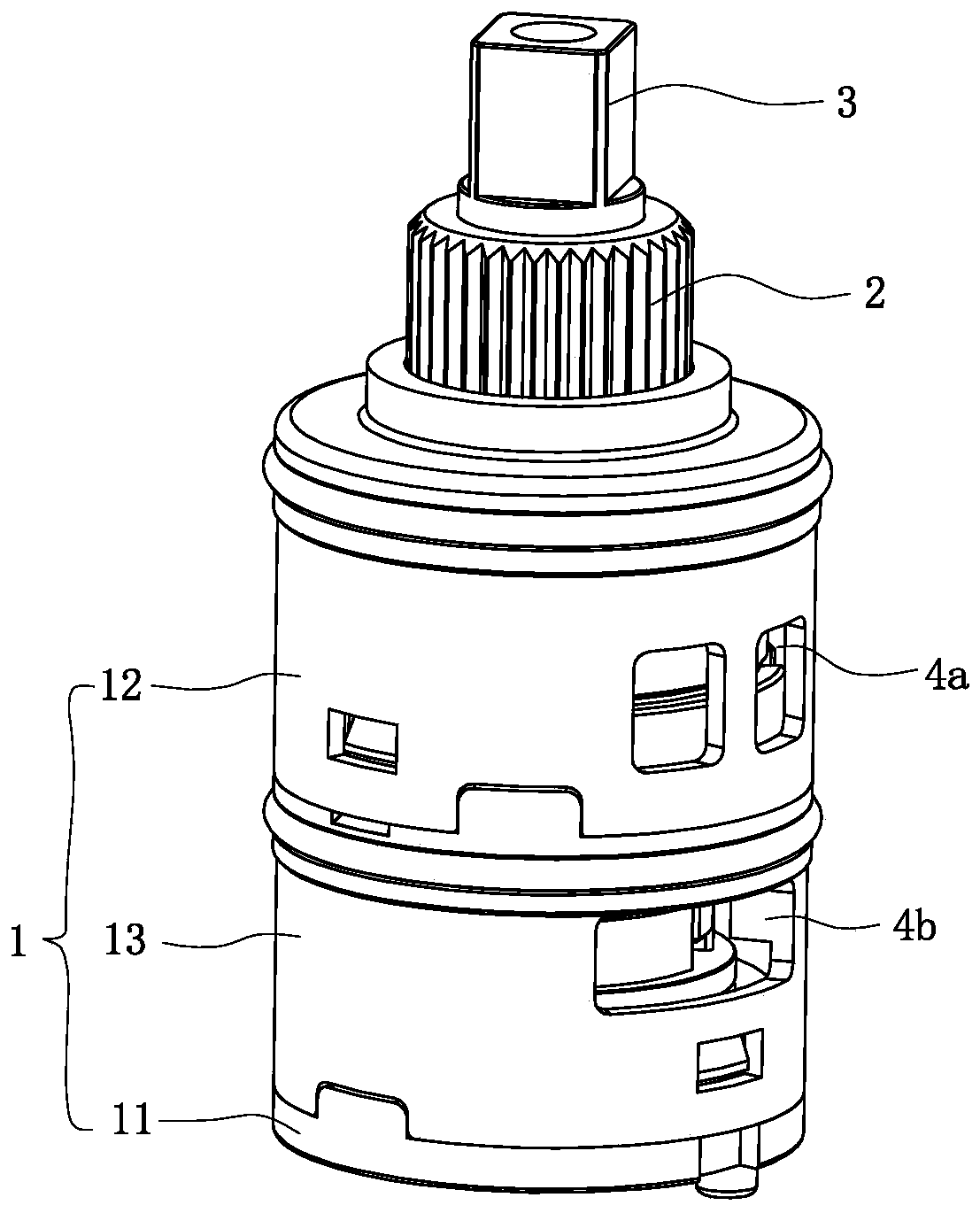

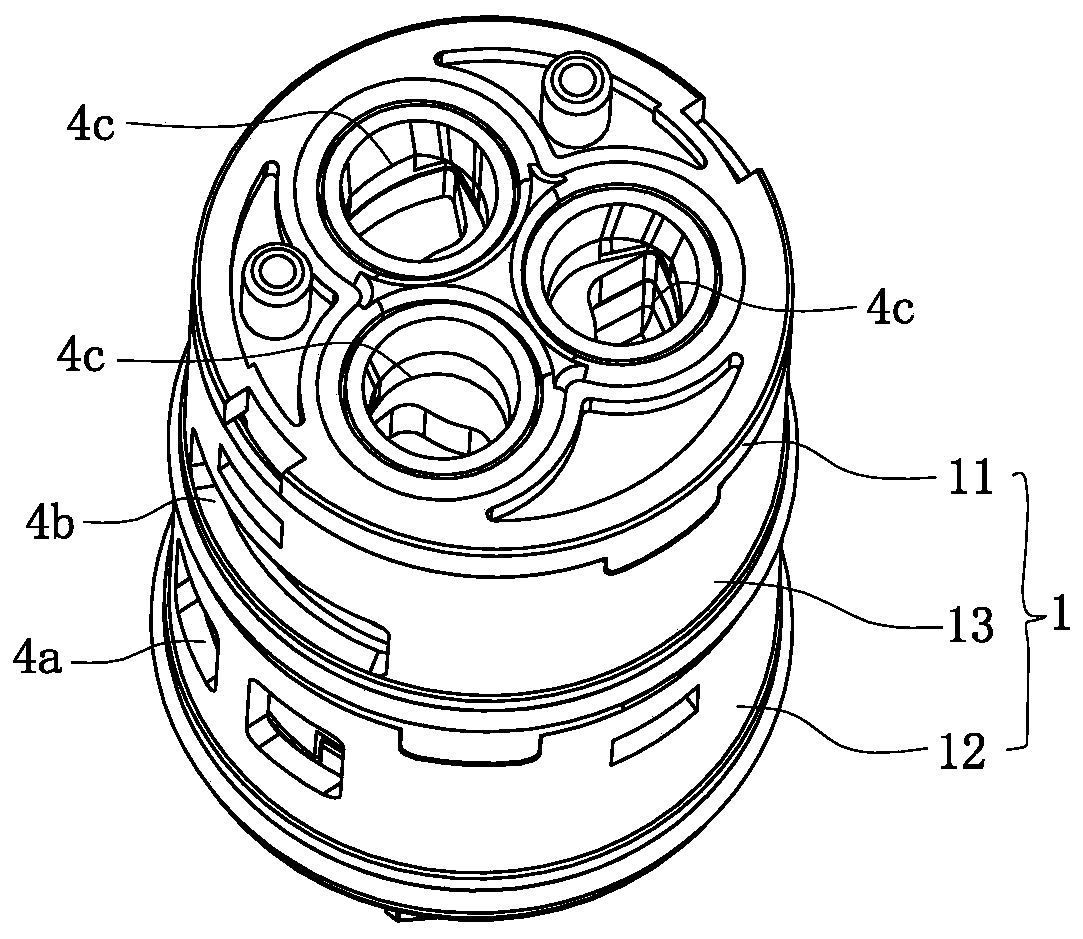

[0041] Such as Figure 1-14 Shown is a preferred embodiment of the present invention.

[0042] A faucet valve core with the function of mixing water and water, including a valve housing 1, a water mixing operation valve stem 2, a water diversion operation valve stem 3, and a water mixing valve plate assembly 5 and a water diversion valve plate located in the valve housing 1 Component 6; the valve housing 1 is provided with a first water inlet 4a, a second water inlet 4b and a plurality of water outlets 4c, and there are three water outlets 4c in order to adapt to the spraying device equipped with a shower, a top spray and a faucet.

[0043] The water mixing operation valve rod 2 is connected with the mixing water valve plate assembly 5, and the mixing water valve plate assembly 5 can be controlled by the water mixing operation valve rod 2 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com