Thermal power plant boiler capable of controlling waste residue discharge

A technology for thermal power plants and boilers, applied in the field of boilers in thermal power plants, can solve problems such as blockage of the discharge port, affecting the normal use of the boiler, affecting the combustion of fuel, etc., to achieve the effect of boiler stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

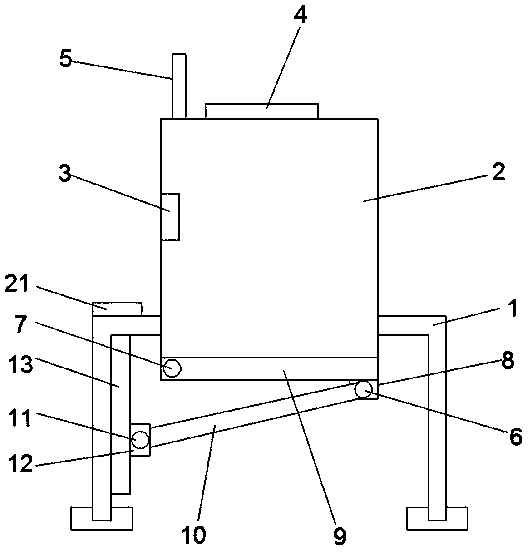

[0022] see Figure 1-2 According to an embodiment of the present invention, a thermal power plant boiler capable of controlling waste slag discharge includes a support frame 1 on which a boiler 2 is fixed, and the support frame 1 supports the boiler 2 as a whole function, the boiler 2 is fixed with an infrared sensor 3, through which the infrared sensor 3 is installed to sense and detect the position of the waste slag in the boiler 2, and the top of the boiler 2 is provided with a feed port 4, through the feed port 4, to the Fuel is put into the boiler 2, and an exhaust pipe 5 is fixedly connected to one side of the feed port 4, and gas is discharged through the exhaust pipe 5. The bottom of the boiler 2 is provided with a baffle 9, and through the baffle 9, the The waste slag plays a supporting role, and the baffle plate 9 is connected with the boiler 2 through the movable shaft-7, and is movably connected by being provided with the movable shaft-7, so as to facilitate the op...

Embodiment 2

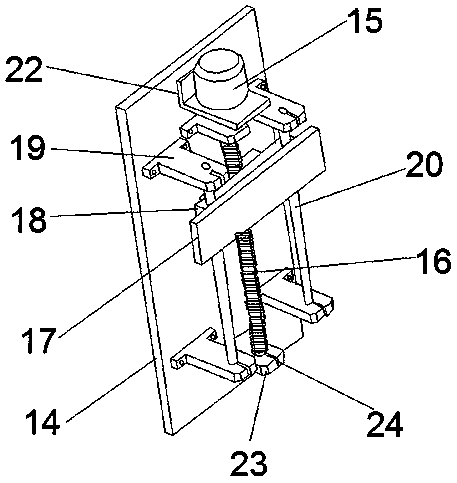

[0024] see Figure 1-2 , for the support frame 1, the support frame 1 is fixed with a controller 21, the controller 21 is electrically connected with the infrared sensor 3 and the motor 15, and the controller 21 is connected to the The infrared sensor 3 is electrically connected with the motor 15. When the infrared sensor 3 senses that the amount of waste residue increases, a signal will be sent to the controller 21, and the controller 21 will control the motor 15 to work, so that the waste residue can be discharged in time. As for the fixing plate 14 , a motor base 22 is fixed on the fixing plate 14 , the motor 15 is fixed on the motor base 22 , and the motor 15 is fixed by the motor base 22 . As for the fixing plate 14 , the second supporting plate 23 is symmetrically arranged on the fixing plate 14 , and the screw 16 penetrates through the second supporting plate 23 . For the support plate one 19, the tops of the support plate one 19 and the support plate two 23 are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com