Tension and torsion composite in-situ tester applicable to neutron diffraction Euler ring

A tester, in-situ technology, applied in the direction of material analysis using wave/particle radiation, testing material strength using stable tension/pressure, instruments, etc., which can solve the problem of single load action, unable to study atomic structure or magnetic structure. Changes and other problems to achieve the effect of improving the measurement accuracy and simplifying the data analysis and processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

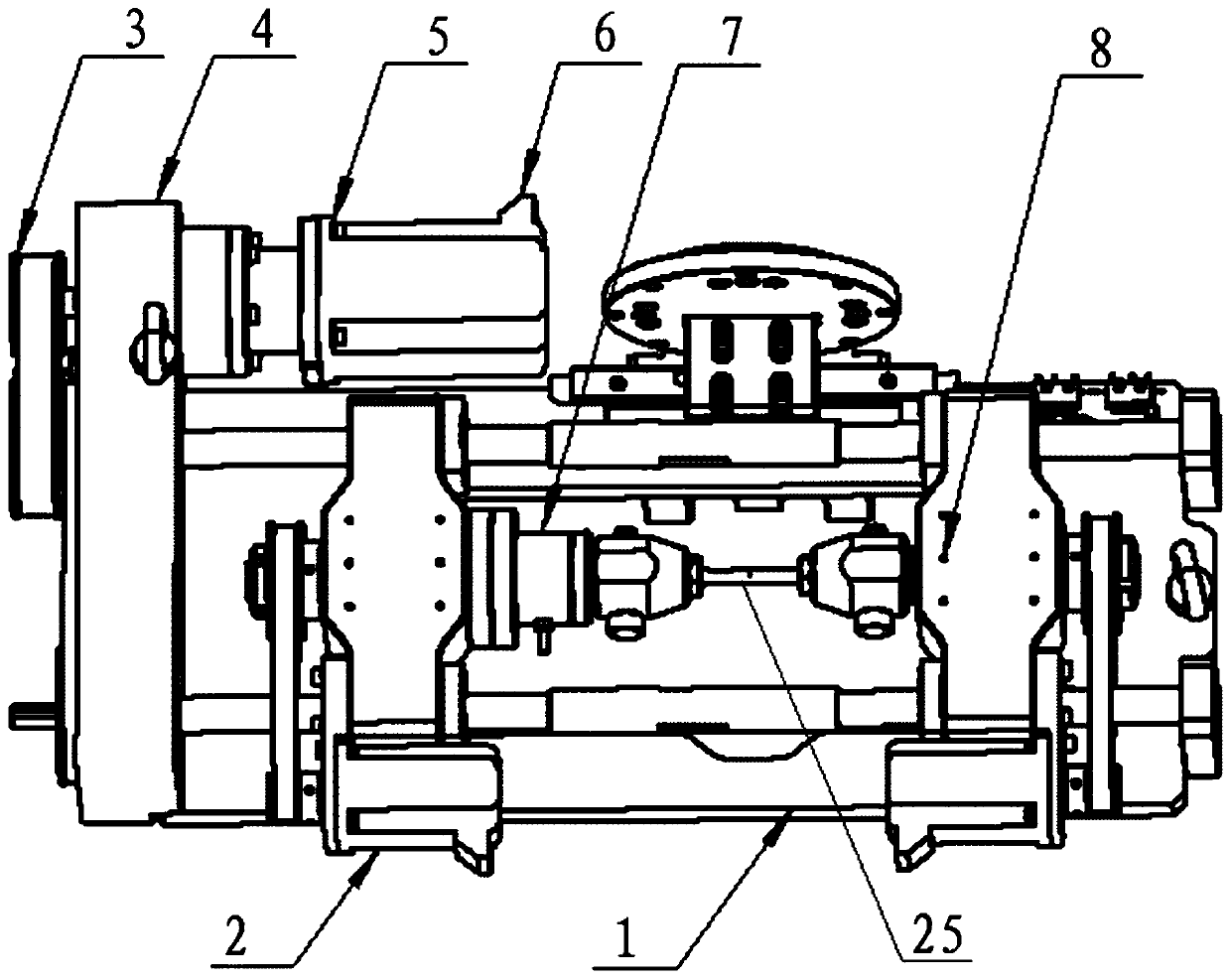

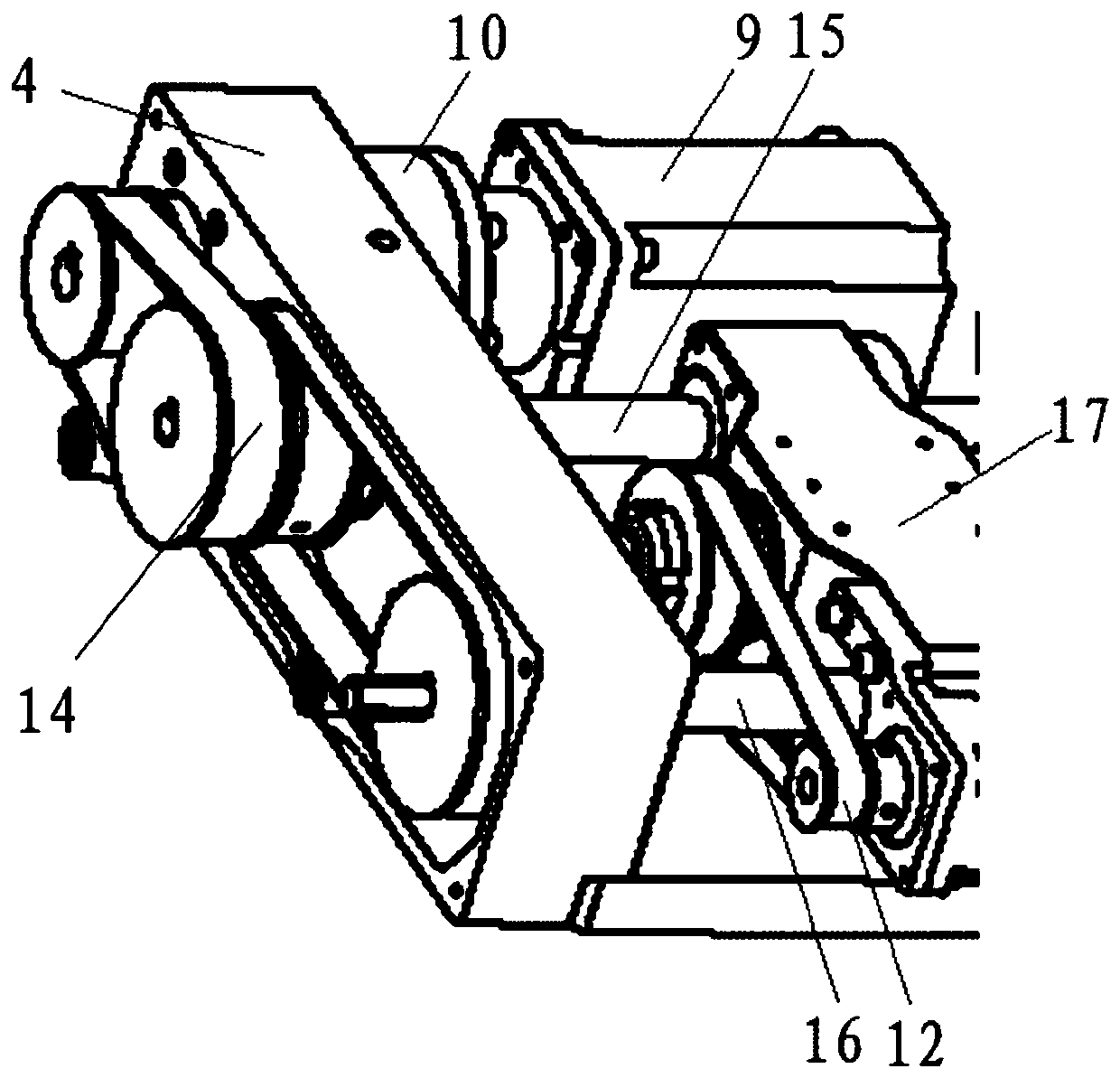

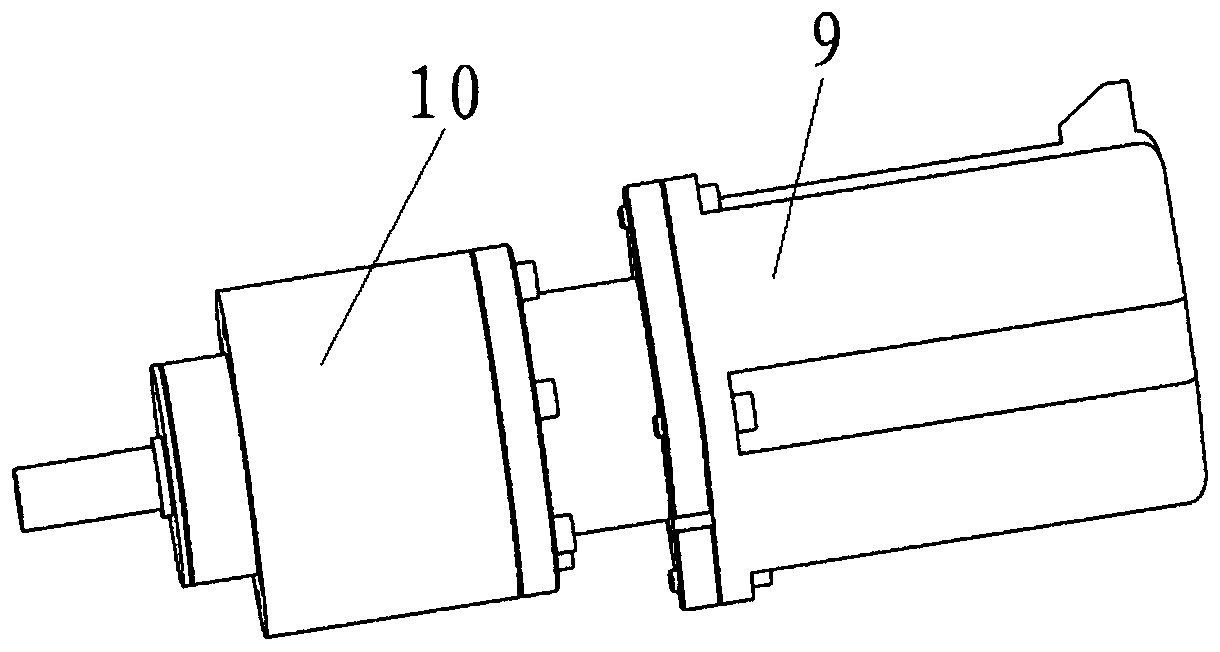

[0031] Such as figure 1 As shown, the present invention provides a pull-twist compound in-situ tester suitable for neutron diffraction Euler rings, including a base plate 1, a synchronous rotation unit 2, a transmission unit 3, a support seat 4, a drive unit 5, and a displacement detection unit 6. Load testing device 7, sample stretching unit 8, and central controller and other components (the central controller is not marked).

[0032] The driving unit 5 and the sample stretching unit 8 are arranged on the bottom plate 1 through the support base 4, the driving unit 5 drives the sample stretching unit 8 to perform a tensile test on the sample 25 through the transmission unit 3, and the driving unit 5 is used to provide The power of the sample stretching;

[0033] The transmission unit 3 is used to transmit the power to the sample stretching unit 8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com