Toner cartridge

A toner cartridge and toner technology, used in electrographics, optics, instruments, etc., can solve problems such as poor printing, uneven powder application, and complexity, and achieve stable printing quality, fewer parts, and fewer assembly processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

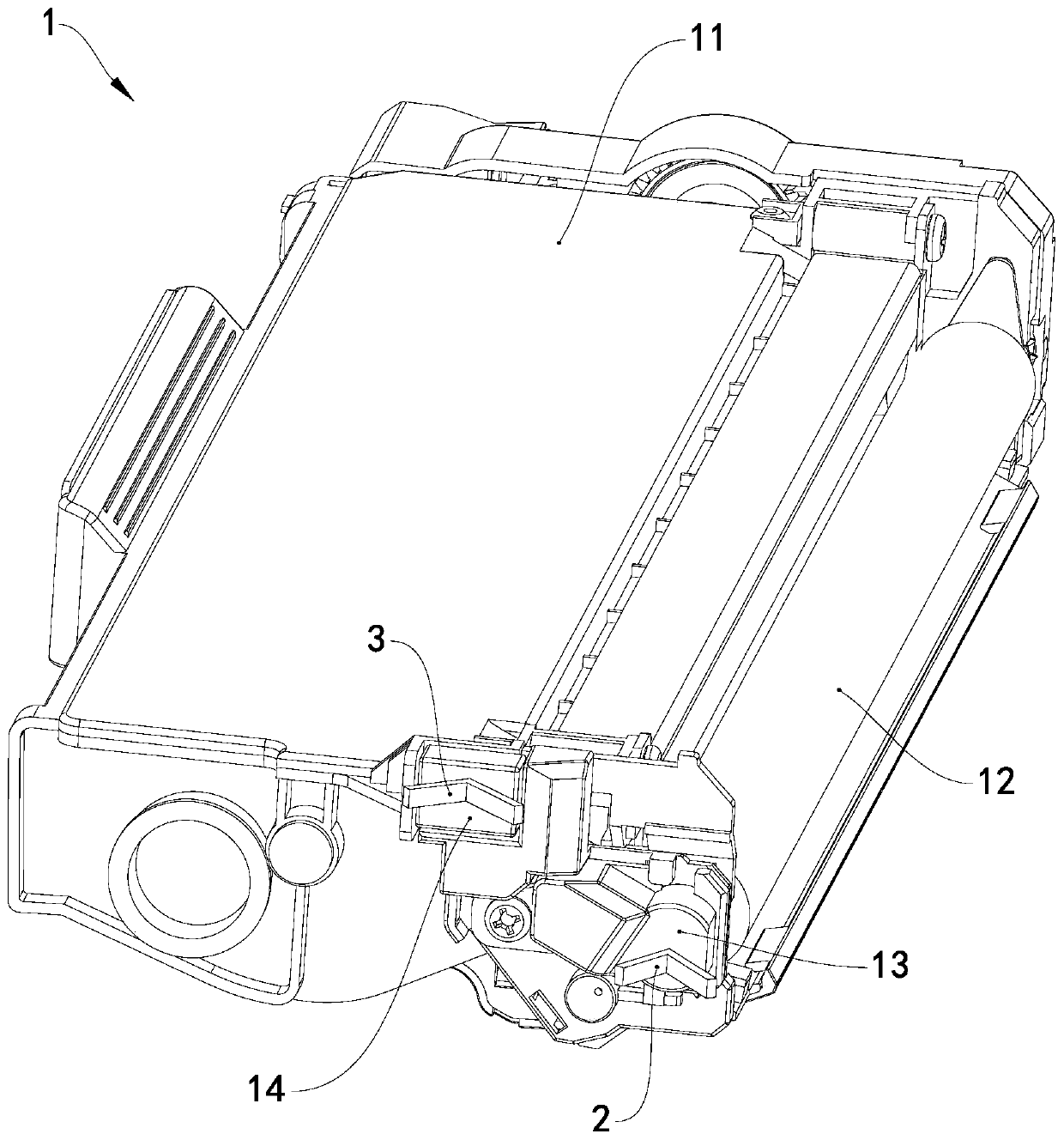

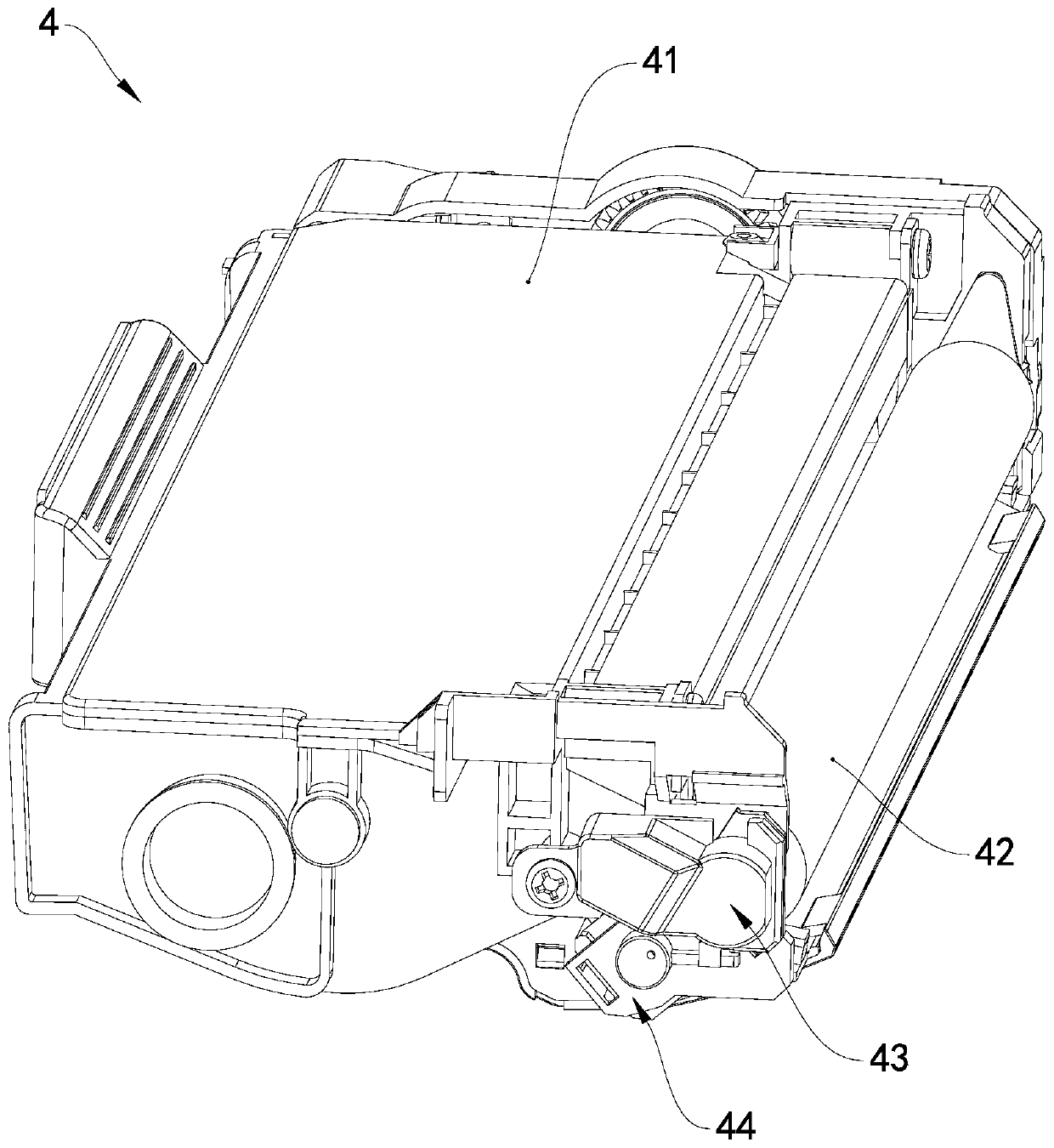

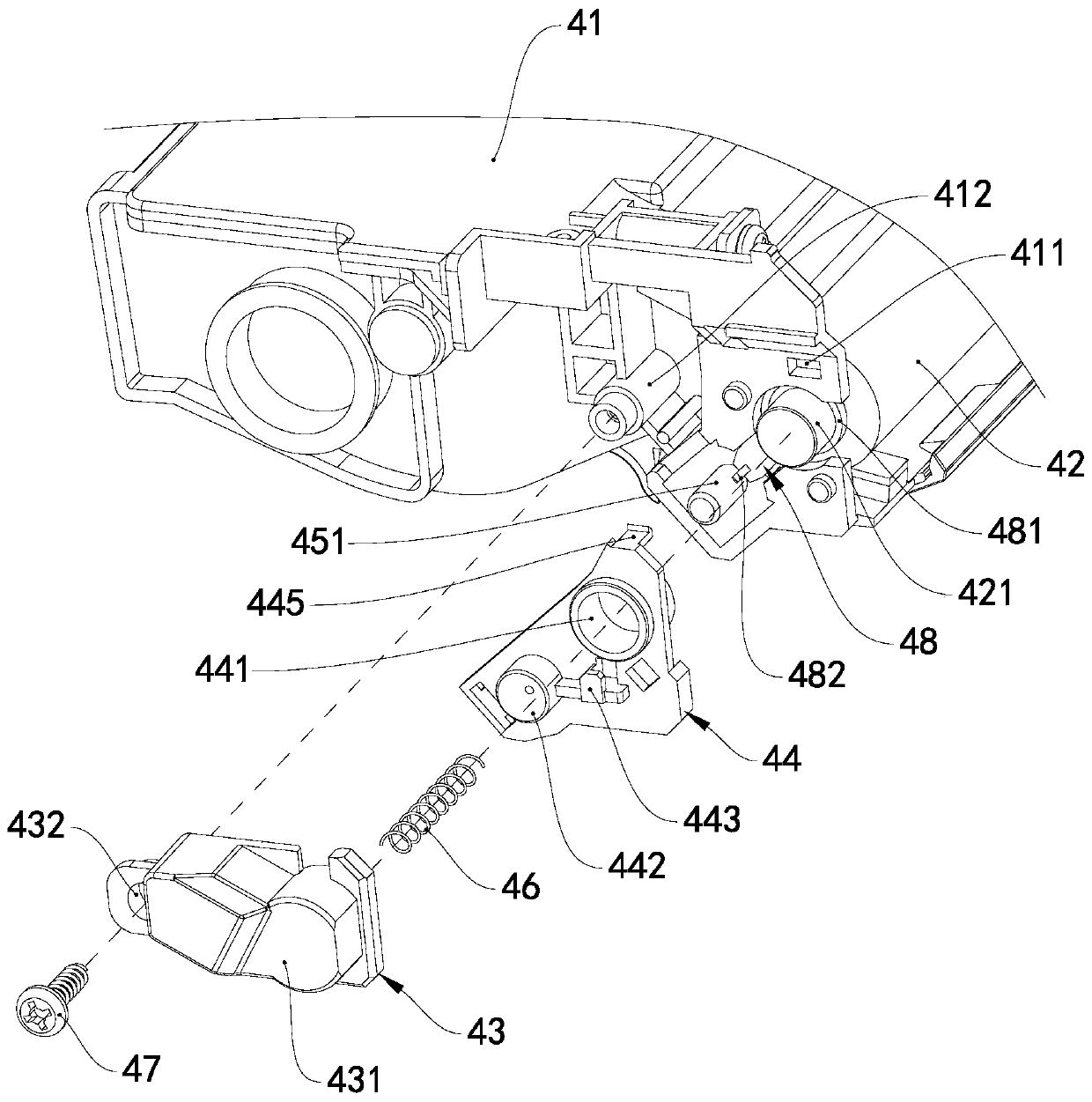

[0032] see figure 2 and image 3 , the toner cartridge 4 includes a box body 41, a developing roller 42, a powder feeding roller, a conductive plastic part 43, a metal part 48 and a bearing 44, the box body 41 has a toner cavity for accommodating carbon powder, the conductive plastic part 43 and the metal part 48 Located outside the same end wall of the box body 41 . The developing roller 42 is rotatably supported between the two end walls of the box body 41 , and the developing roller 42 includes a developing roller shaft 421 supported on the two end walls of the box body 41 . The powder feeding roller is rotatably supported between the two end walls of the box body 41 , and the powder feeding roller includes a powder feeding roller shaft 451 supported on the two end walls of the box body 41 .

[0033] see Figure 4 , the conductive plastic part 43 has an electrical contact portion 431 and an output portion 433 , the electrical contact portion 431 is used to contact an ou...

no. 2 example

[0039] As an explanation of the second embodiment of the toner cartridge of the present invention, only the differences from the first embodiment of the toner cartridge will be described below.

[0040] see Figure 10 and Figure 11 , the toner cartridge 5 includes a box body 51, a developing roller 52, a powder feeding roller, a conductive plastic part 53, a metal part 55 and an end cover 54, and the conductive plastic part 53 has an electrical contact contact part 532 and an output part 533, and the electrical contact The contact part 532 is used to contact with an output electrical contact of the imaging device, and the output part 533 is in contact with one end of the powder feeding roller shaft 561 . The end cover 54 is installed on one end wall of the box body 51 , and the output part 533 is located between the end cover 54 and the box body 51 .

[0041] see Figure 12 , the conductive plastic part 53 also has a main body 531 , and the electrical contact portion 532 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com