Auxiliary maintenance device and method for tandem cold rolling mill

A technology for a cold tandem rolling mill and an overhaul device, which is applied to chemical instruments and methods, cleaning methods and utensils, and cleaning methods using liquids, etc. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The present invention will be further described in detail below with reference to the accompanying drawings:

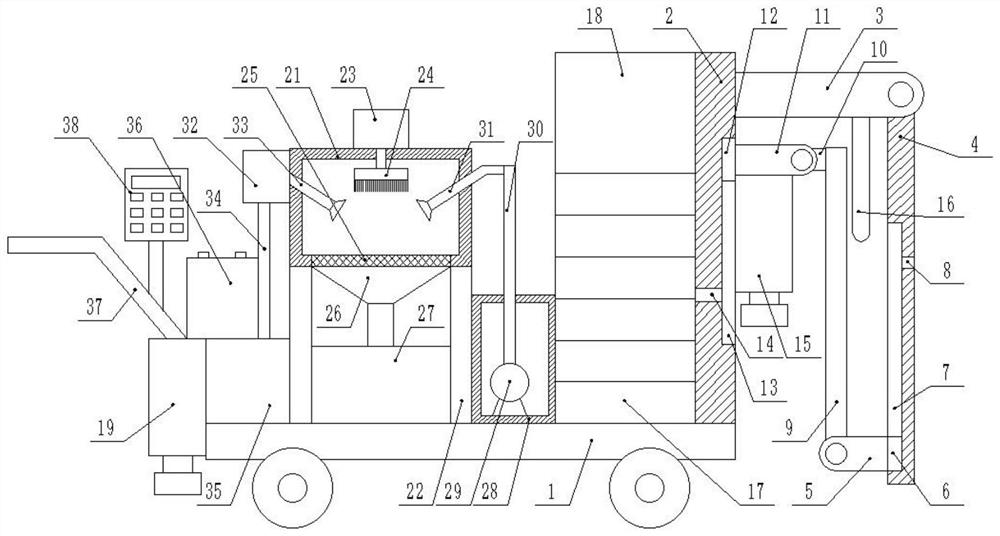

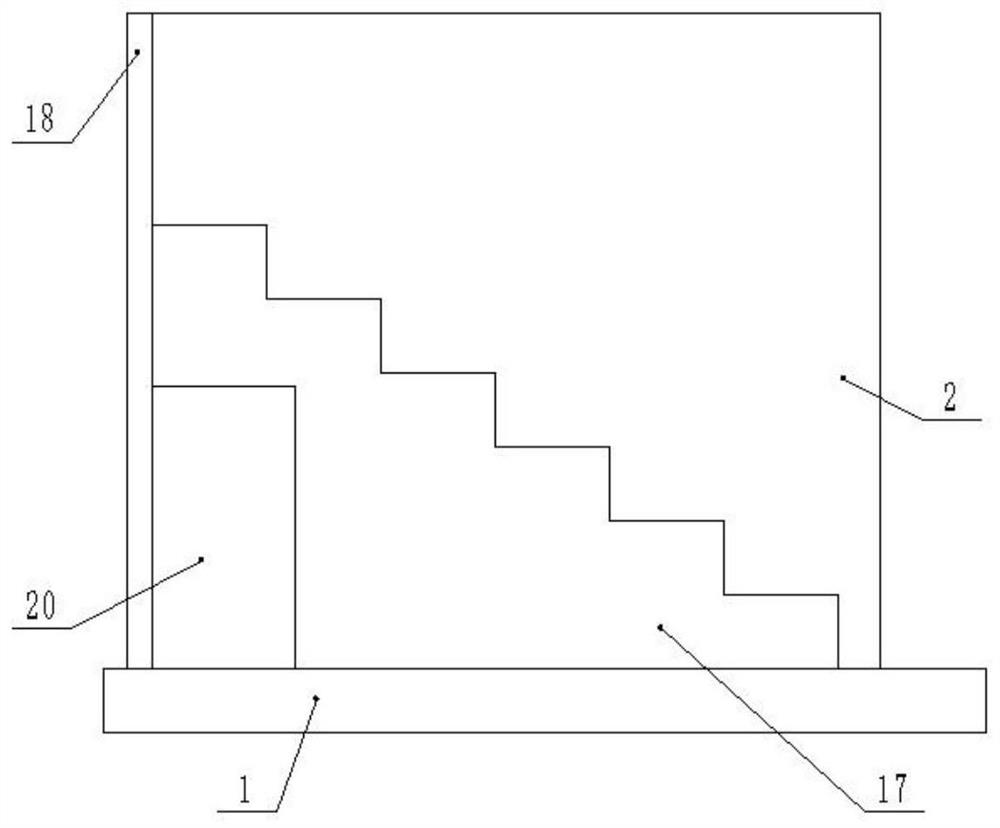

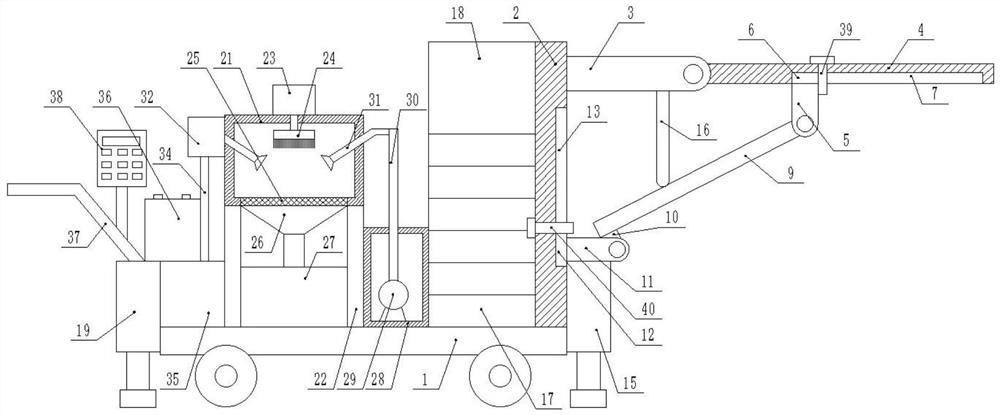

[0029]Such asfigure 1 ,figure 2 ,image 3 withFigure 4As shown, the cold and rolling mill is auxiliary maintenance device, including the upper end side of the truck 1 fixed to support vertical plate 2, and the first connection plate 3 is fixed above the side end, and the first connection plate 3 side ends are rotated to have a platform. The vertical panel 4, the platform vertical panel 4 is provided with a first Swallow 7 toward one end of the support vertical plate 2, and the first Yanchang tail slot 7 is provided with a first swallow tail piece 6 and sliding thereof, and the first Swallow block 6 side end is fixed. The second connecting plate 5, the second connecting plate 5 side ends are rotated to be connected to the support rod 9, and the platform vertical bolt 4 is provided with a first restricted bolt hole 8, and the support rod 9 is fixed to the side end, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com