Ceramic chip boxing machine

A ceramic sheet and cartoning machine technology, applied in packaging and other fields, can solve problems affecting production efficiency, achieve high labor costs, high error rates, and liberate labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

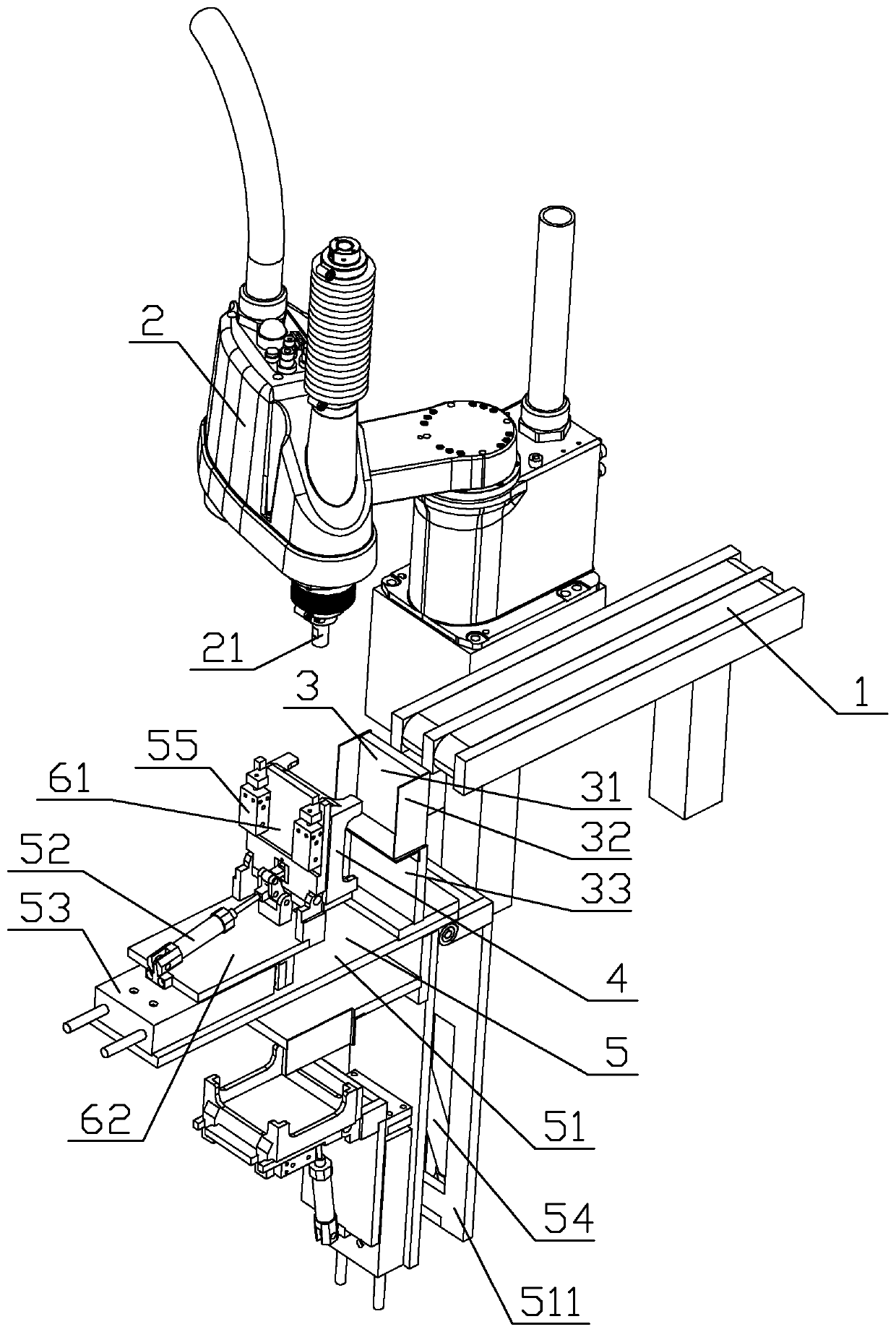

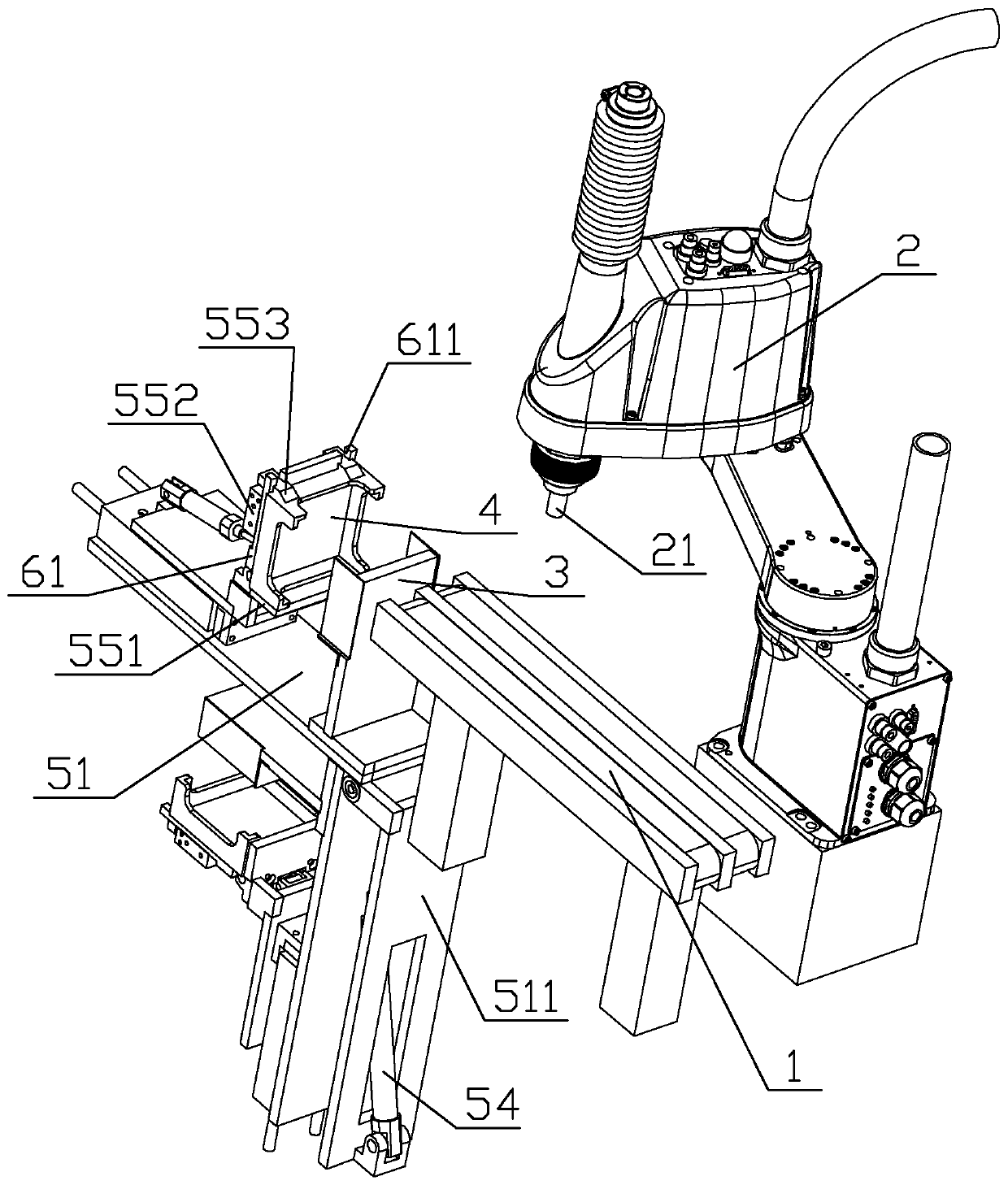

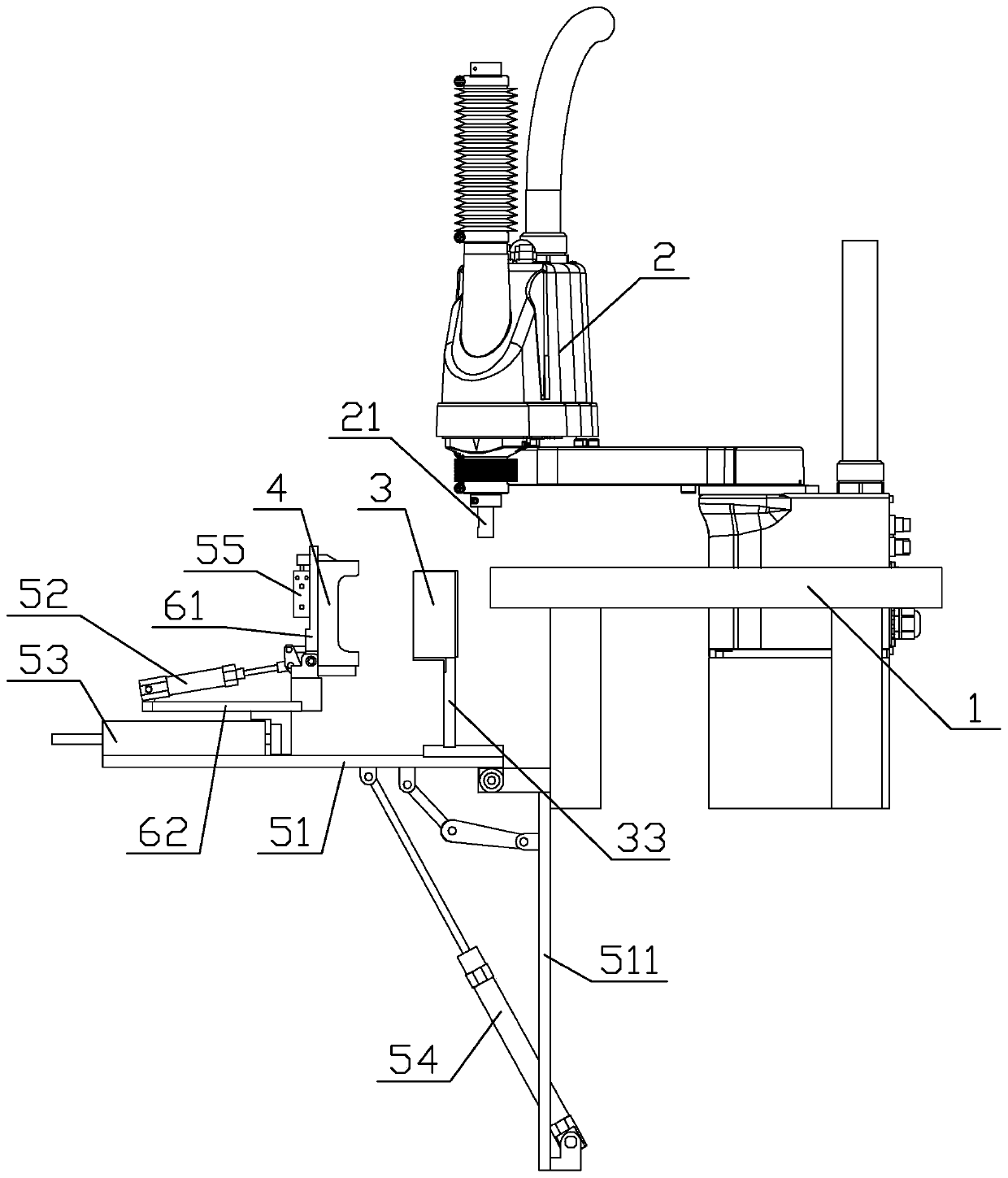

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] Such as figure 1 , 2 , 3, 4, 5, 6, and 7 show a specific embodiment of the ceramic sheet cartoning machine of the present invention. This embodiment comprises input belt 1, manipulator 2, placement groove 3, crucible 4 and packing assembly 5, and manipulator 2 is arranged on the output end of input belt 1 and is used for conveying the ceramic sheet on the input belt 1 to placement groove 3; The assembly 5 includes a rotating frame 51, a first driving cylinder 52, a second driving cylinder 53, a third driving cylinder 54, and a clamping mechanism 55; the placement slot 3 and the crucible 4 are arranged in sequence at the rear of the input belt 1 and arranged on the rotating frame 51, the placement groove 3 is rectangular and has two openings, top and side, the crucible 4 is in a vertical state with the placement groove 3 at the initial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com