Intelligent control printing die-cutting integrated machine

An intelligent control, all-in-one technology, used in printing presses, rotary presses, printing and other directions, can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

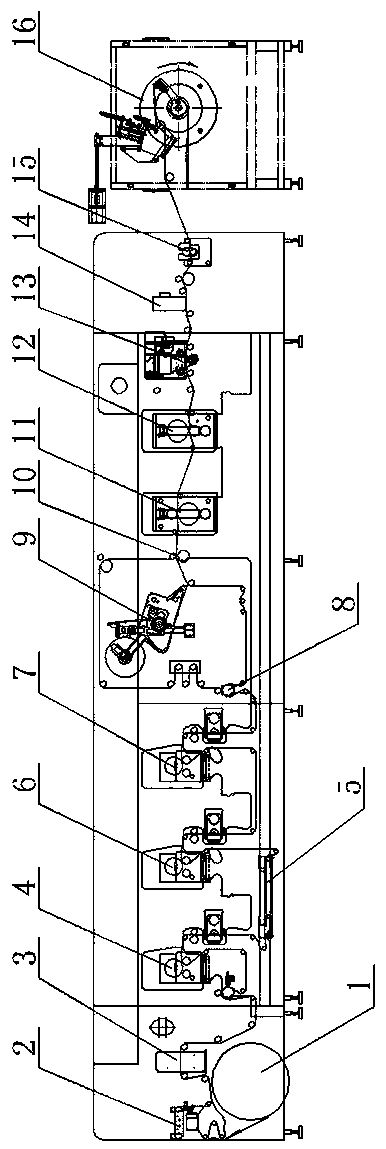

[0015] As shown in the figure, the intelligent control printing and die-cutting integrated machine of the present invention includes an unwinding part 1, a deviation correcting part 2, a first flexo printing part 4, a reversing frame 5, and a second flexo printing part 6 arranged in sequence according to the working order , the third flexo printing part 7, peeling part 8, composite part 10, back circular die cutting part 11, front circular die cutting part 12, detection part 13, marking part 14, slitting part 15 and non-stop winding part 16 In the middle of the peeling part 8 and the composite part 10, a label inserting part 9 is arranged, and a dedusting station 3 is reserved behind the deviation correcting part 2.

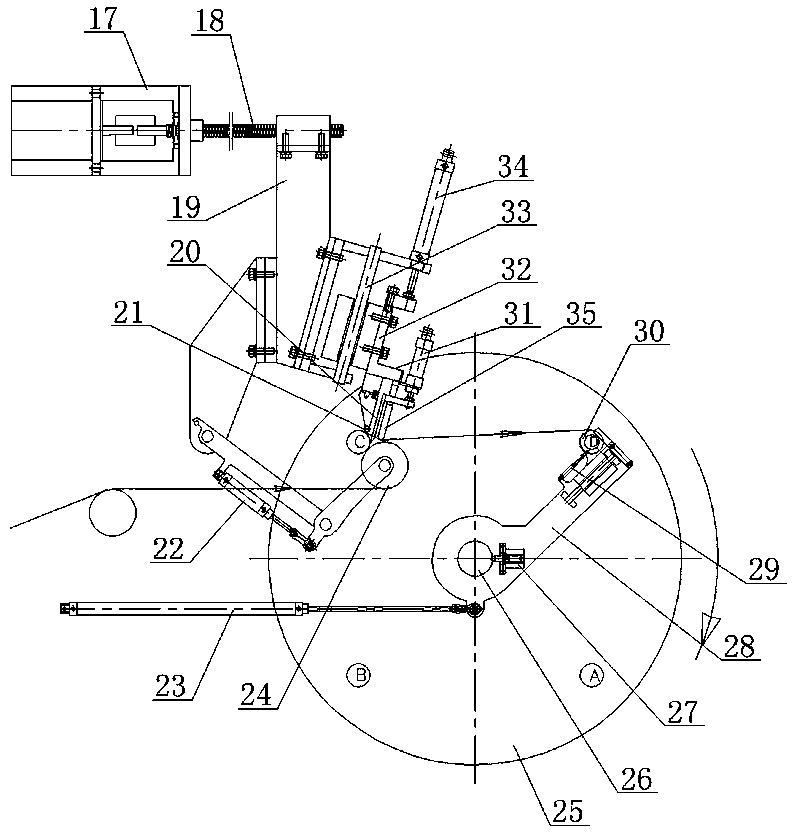

[0016] The non-stop rewinding part 16 includes a rewinding turntable 25, which is set for indexing and rotating. The rewinding turntable 25 is fixedly mounted on the turntable shaft 26. D four winding shafts, the position of the upper left winding shaft C is the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap