Grouting embedded pipe underground laying method in landslide dam diaphragm wall construction

A technology of pre-embedded pipes and damming bodies is applied in excavation, river weirs, marine engineering and other directions, which can solve the problems of difficult hole shape control, increase engineering cost, and high demolition cost, so as to improve the efficiency of substructures and reduce the cost of demolition. The effect of touching the probability and ensuring the verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

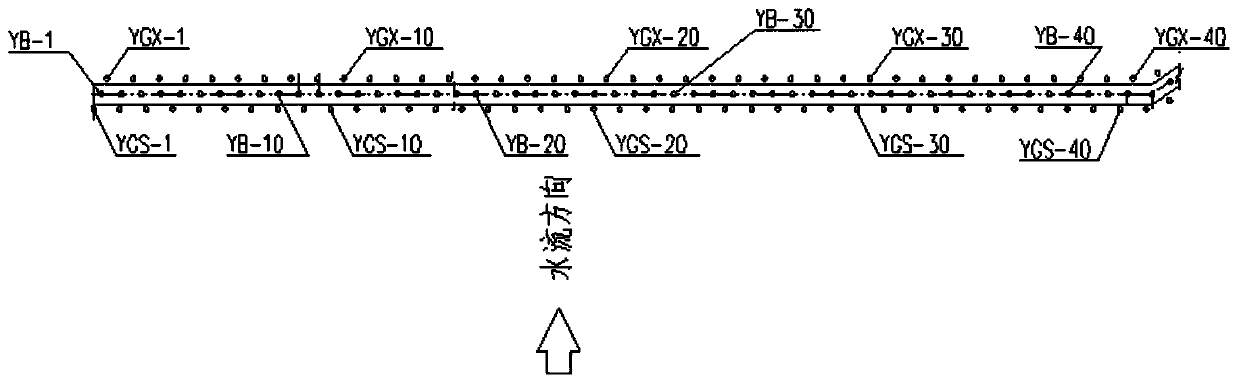

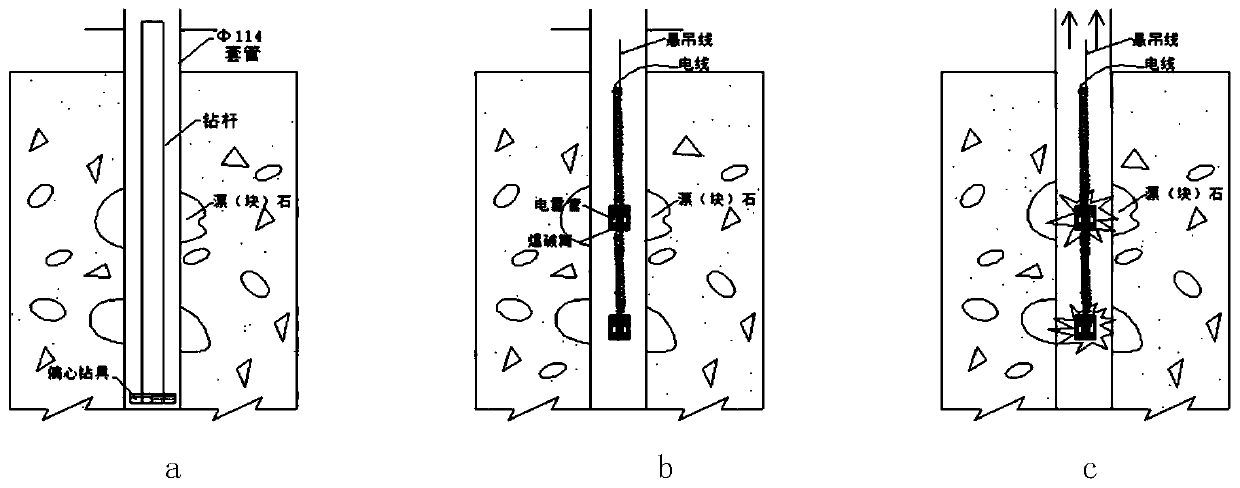

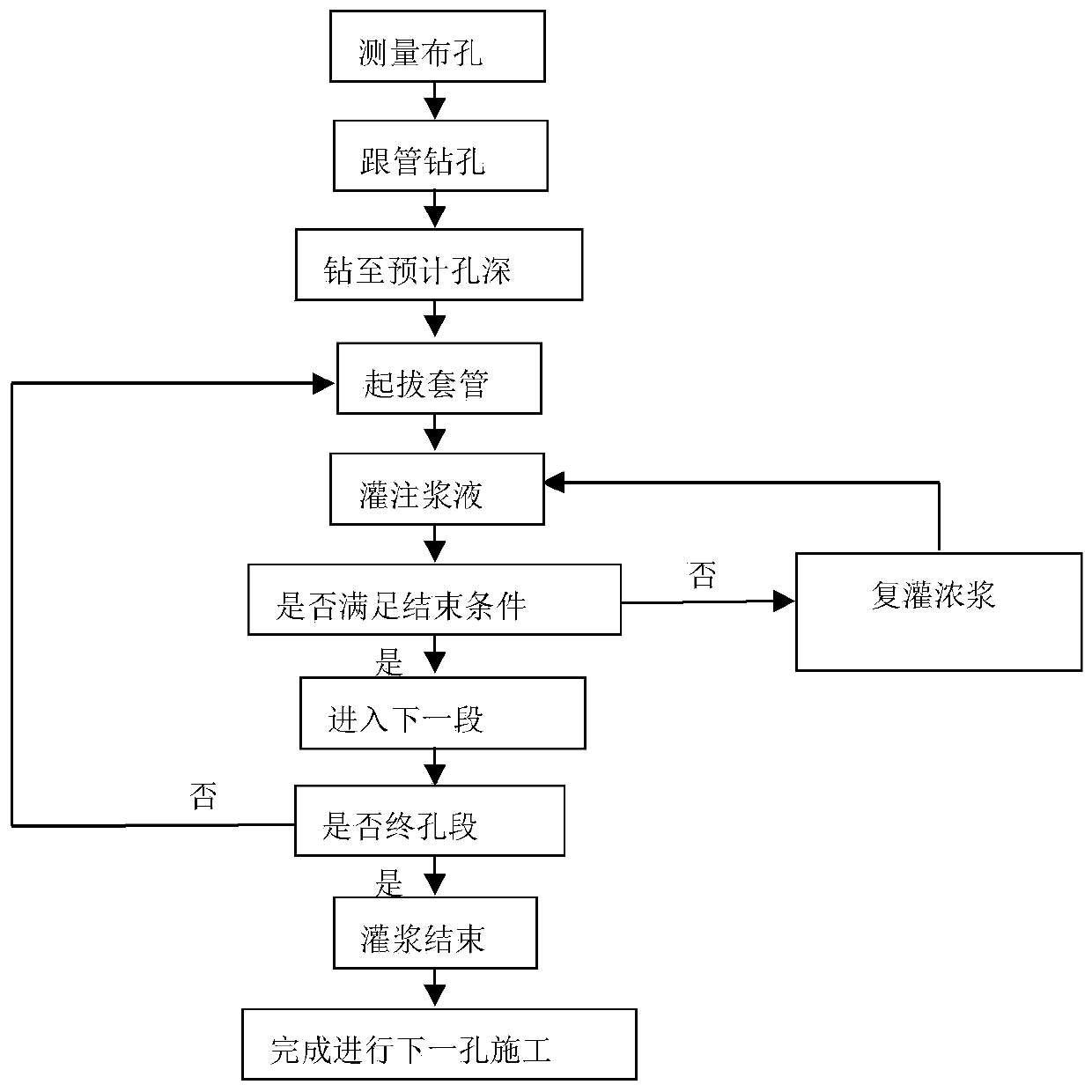

[0058] The anti-seepage system of the damming body improvement project is the core of the reservoir of the dammed lake improvement project. The anti-seepage system is composed of the damming body anti-seepage wall, the curtain grouting of the ancient landslide body on the left bank and the bedrock curtain grouting on the right bank. For the geological conditions where the depth of the anti-seepage wall exceeds 100m and the maximum depth even exceeds 130m, the thickness of the wall exceeds 1.0m, the content of boulders exceeds 50%, the maximum particle size of the boulders exceeds 15 meters, the phenomenon of overhead is serious, and the stratum has not been deposited and cemented For the extremely complicated dam body, in order to ensure the successful construction of the cutoff wall, the present invention pre-treats the above-mentioned strata before the construction of the cutoff wall, so as to improve the geological conditions of the dam body in advance and prevent the cutoff ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com