Assembly wall, splicing structure and assembly type power distribution station

A substation and prefabricated technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of long construction period and performance requirements that cannot meet the targets, and achieve short construction period, reduce labor dependence, and reduce construction costs. garbage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

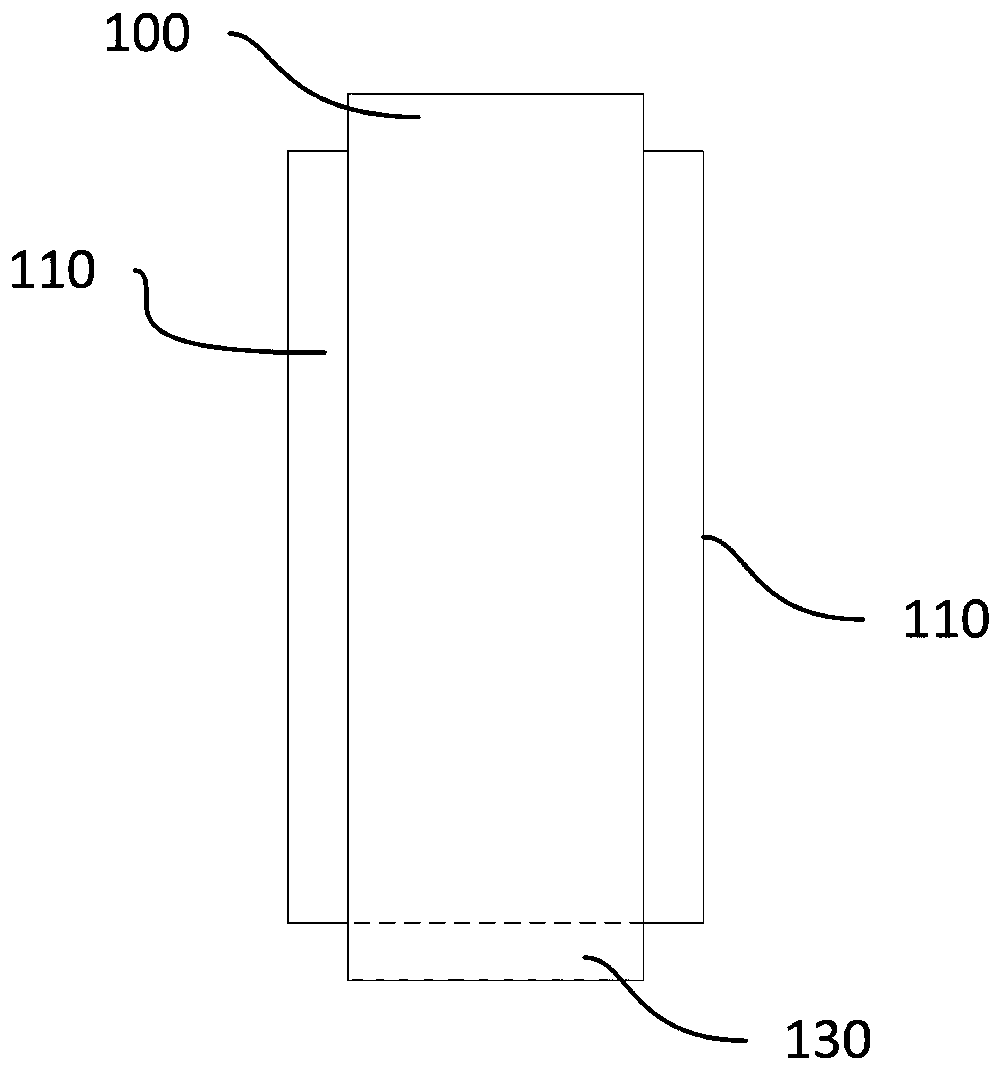

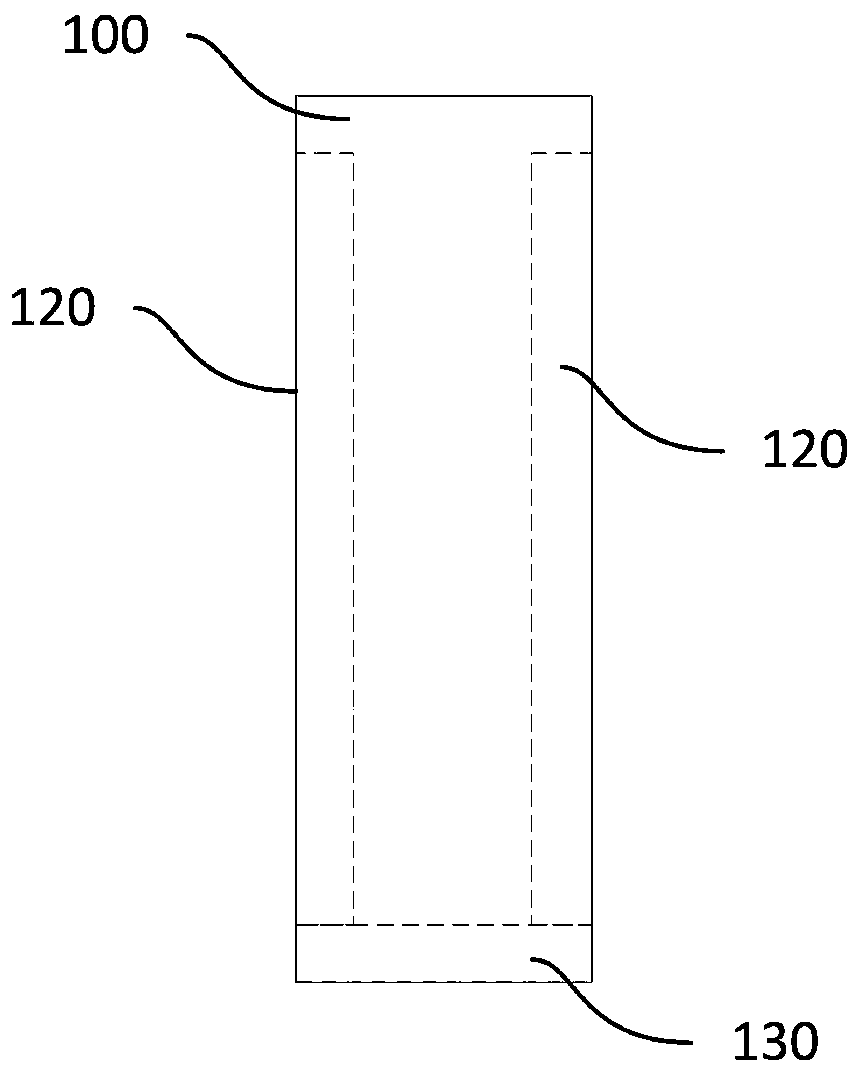

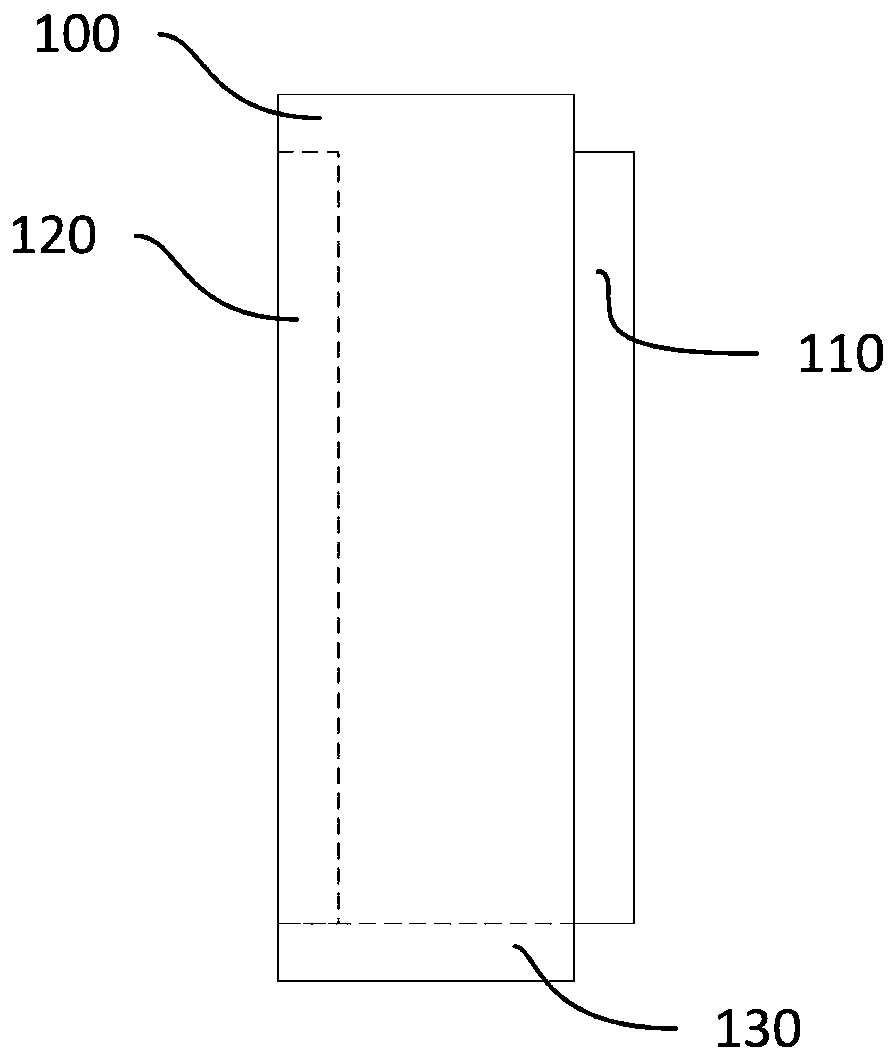

[0029] Such as Figure 1 to Figure 3 As shown, the present invention provides a preferred embodiment of the assembled wall.

[0030] An assembled wall 100, comprising a main body block, splicing pieces arranged on both sides of the main body block for splicing, a notch 130 arranged on the bottom side or / and top layer of the main body block, and the splicing pieces are bosses 110 and grooves 120 One of them, the shape of the boss 110 matches the shape of the groove 120 .

[0031] Specifically, the main body block and the splicing piece are integrally provided, and a plurality of main body blocks are connected laterally on both sides through the mutual cooperation of the boss 110 and the groove 120 to form a wall. Wherein, the main body block is a cube, preferably a cuboid structure with a certain thickness. The two ends of the thickness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com