External circulation ball screw

A ball screw, external circulation technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of inaccurate connection of the return path, unsmooth ball circulation, prolonged assembly time, etc., to improve assembly efficiency, The effect of saving mold cost and shortening the required length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

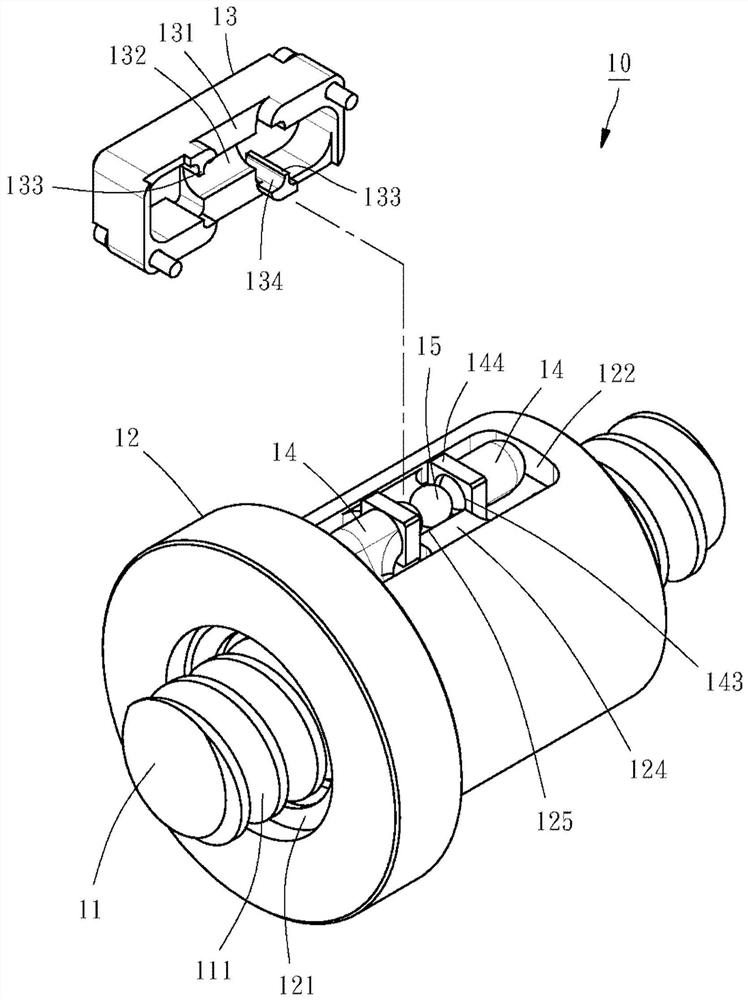

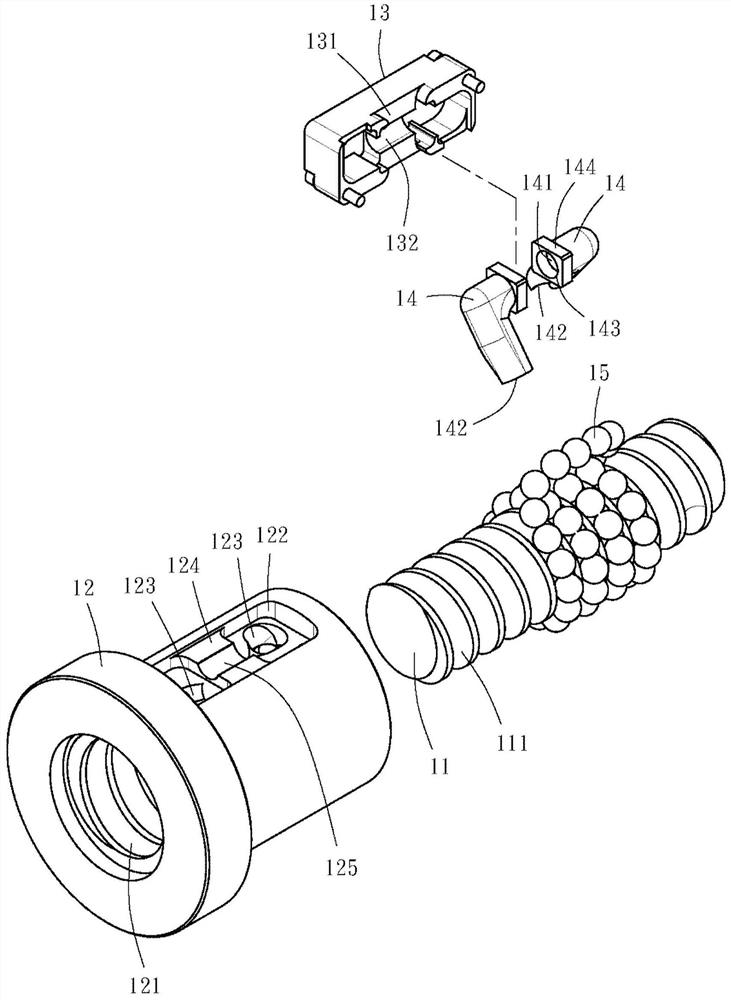

[0037] In order to illustrate the structure and features of the present invention in detail, the following preferred embodiments are exemplified and described as follows with accompanying drawings.

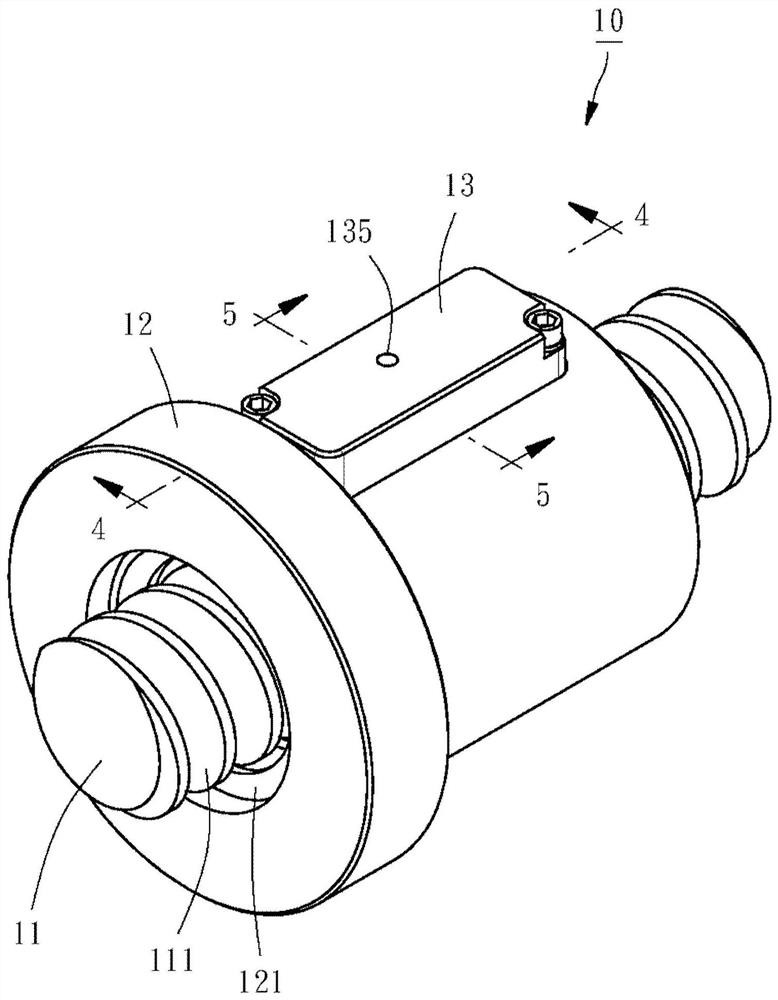

[0038] Such as Figure 1 to Figure 5 As shown, the first preferred embodiment of the present invention provides an external circulation ball screw 10 , which includes a screw shaft 11 , a nut 12 , a cover 13 , two return elements 14 and a plurality of rolling elements 15 .

[0039] The screw shaft 11 has an external thread groove 111 .

[0040] The nut 12 is sheathed on the screw shaft 11 so as to move along the axial direction of the screw shaft 11. The nut 12 has an internal thread groove 121. The internal thread groove 121 of the nut 12 is connected to the screw shaft 11 The external thread grooves 111 together form a load path P1. A groove 122 is formed on the outer surface of the nut 12 , and two return holes 123 are formed in the groove 122 , and each of the return holes 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com