Leakage plugging pipe clip device and locking device for leak plugging pipe clip

A technology of locking device and leaking pipe clamp, applied in the direction of pipe/pipe joint/pipe fitting, pipe element, mechanical equipment, etc., can solve the problems of difficult operation, unsatisfactory locking requirements, high cost, high automation The effect of high probability of success and high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

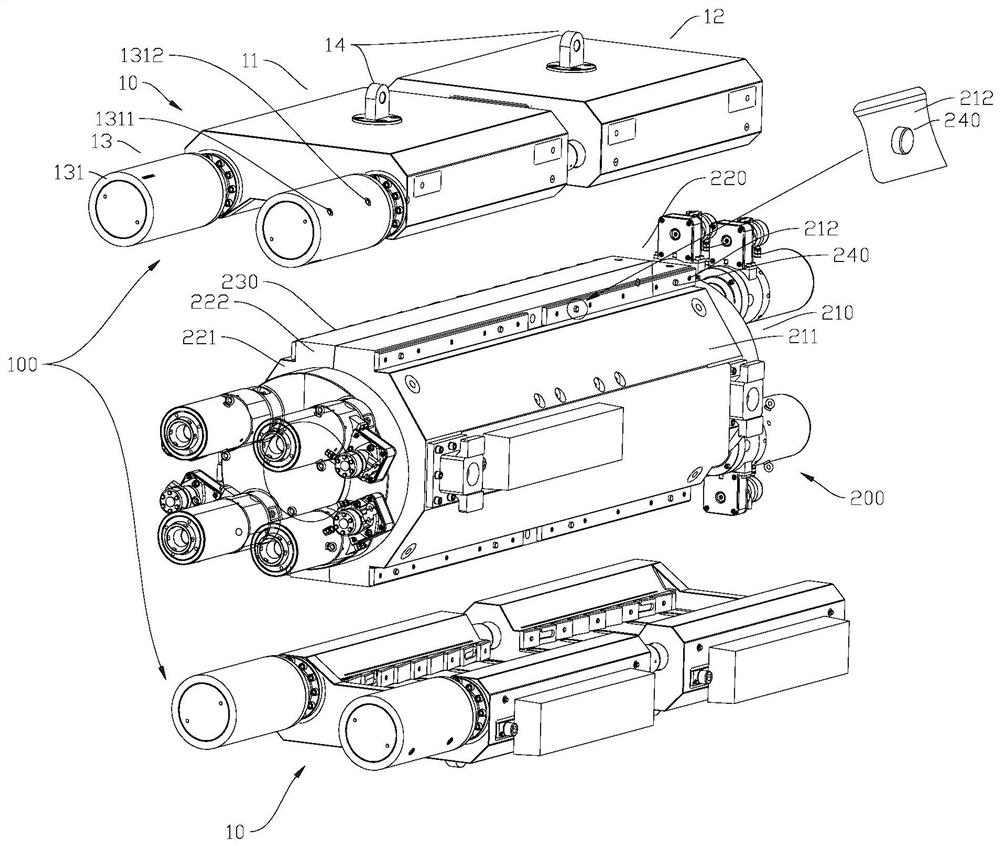

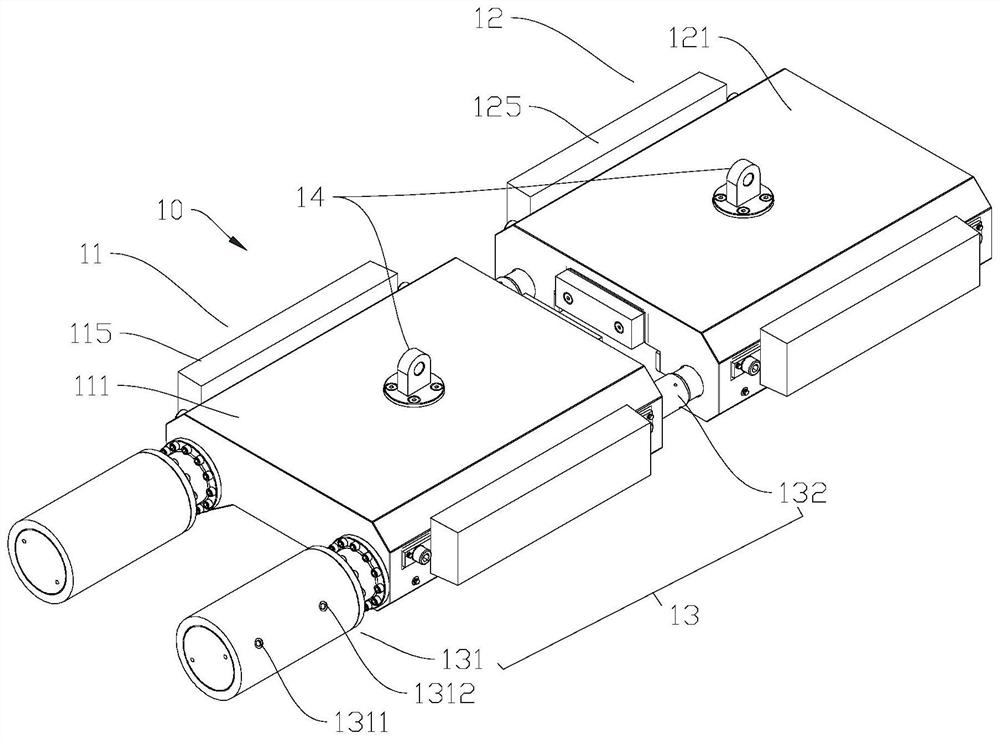

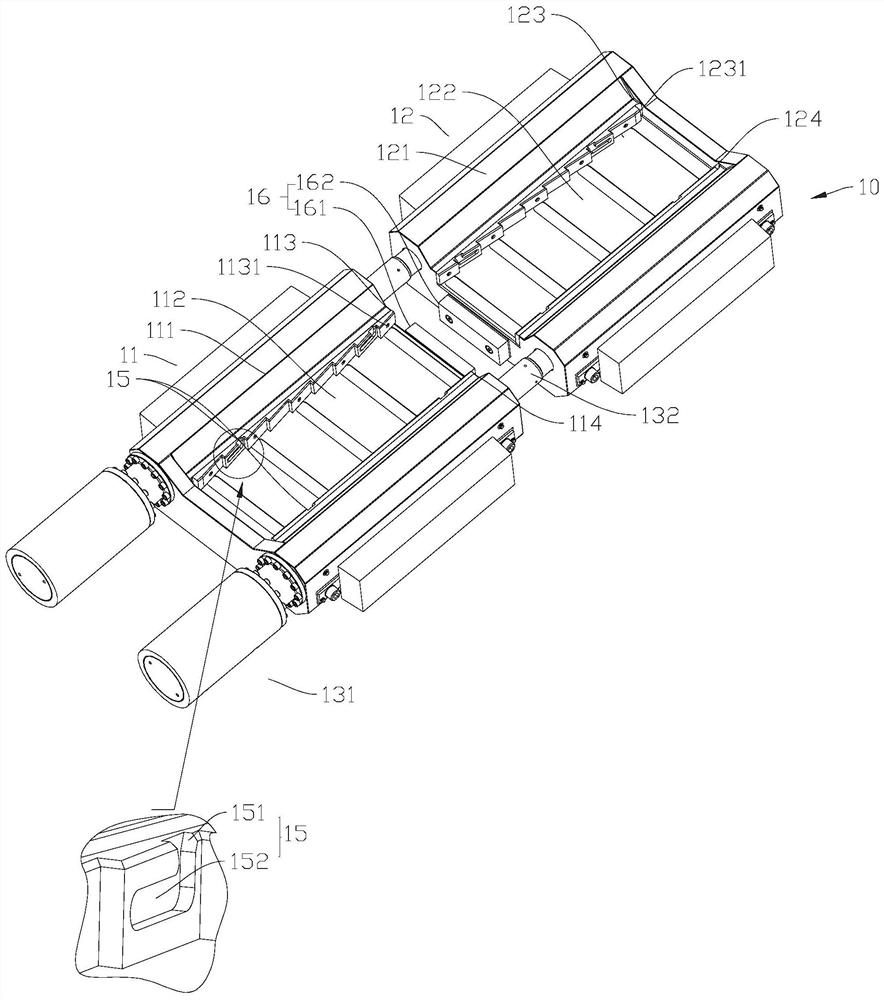

[0038] figure 1 Some preferred embodiments of the leakage plugging pipe clamping device of the present invention are shown. The plugging device can be used for plugging and maintenance of sea pipes in shallow waters within 300 meters, and can also be used for plugging and maintenance of deep-water sea pipes with a water depth of more than 300 meters. This invention gets rid of the traditional bolt locking method only The restriction that divers can enter the water for maintenance has created a new locking method, which is controlled by the ROV operation and control system to achieve unmanned underwater operation and maintenance to achieve locking, which can greatly improve the efficiency and efficiency of ROV underwater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com