Heat pump system and heat pump system grading defrosting starting and ending point judgment method

A heat pump system and criterion technology, applied in defrosting, lighting and heating equipment, household appliances, etc., can solve the problems of large measurement errors in defrosting conditions, poor user comfort, waste of defrosting heat energy, etc., and achieve improved stability performance, improve energy efficiency, and improve user comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

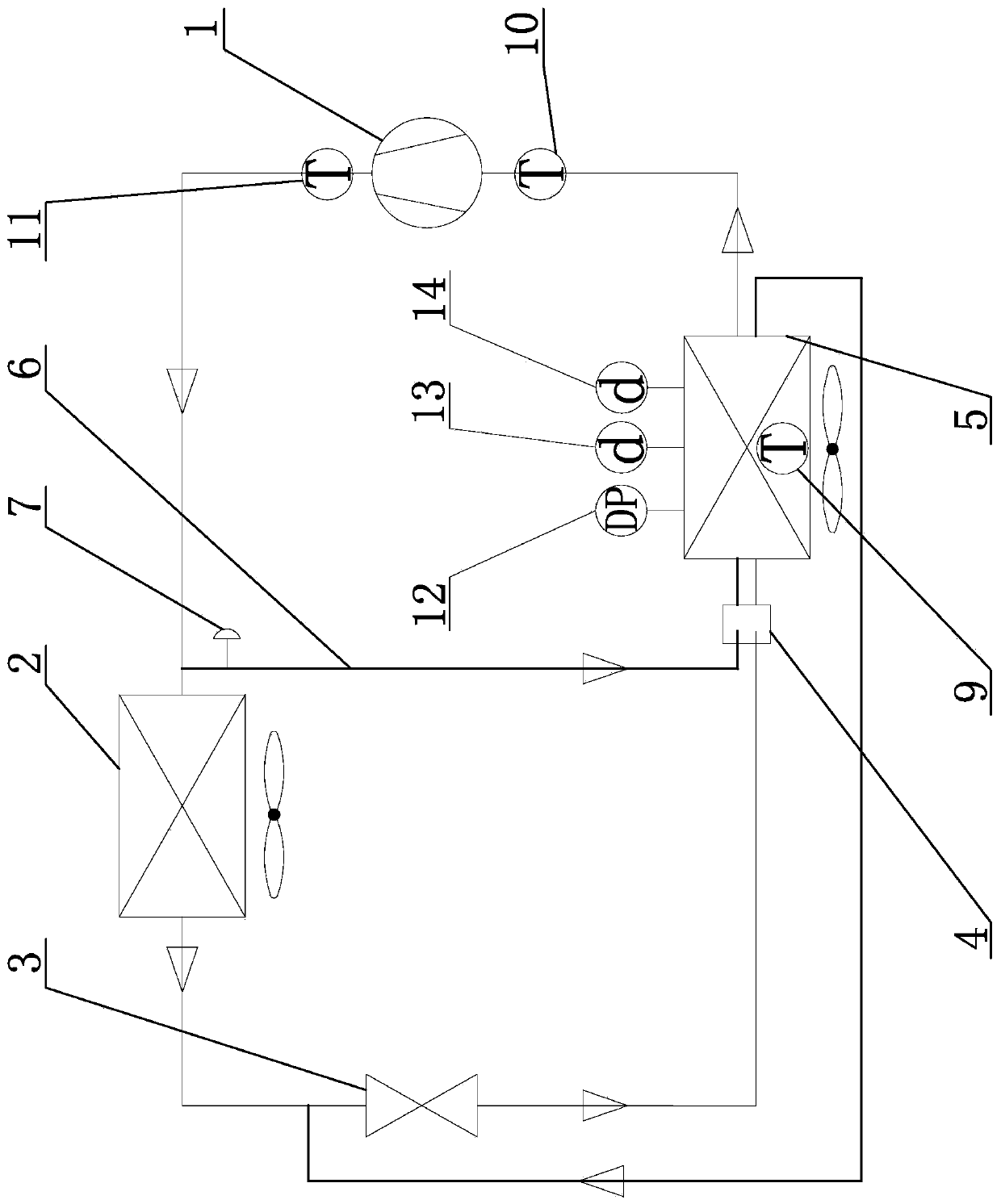

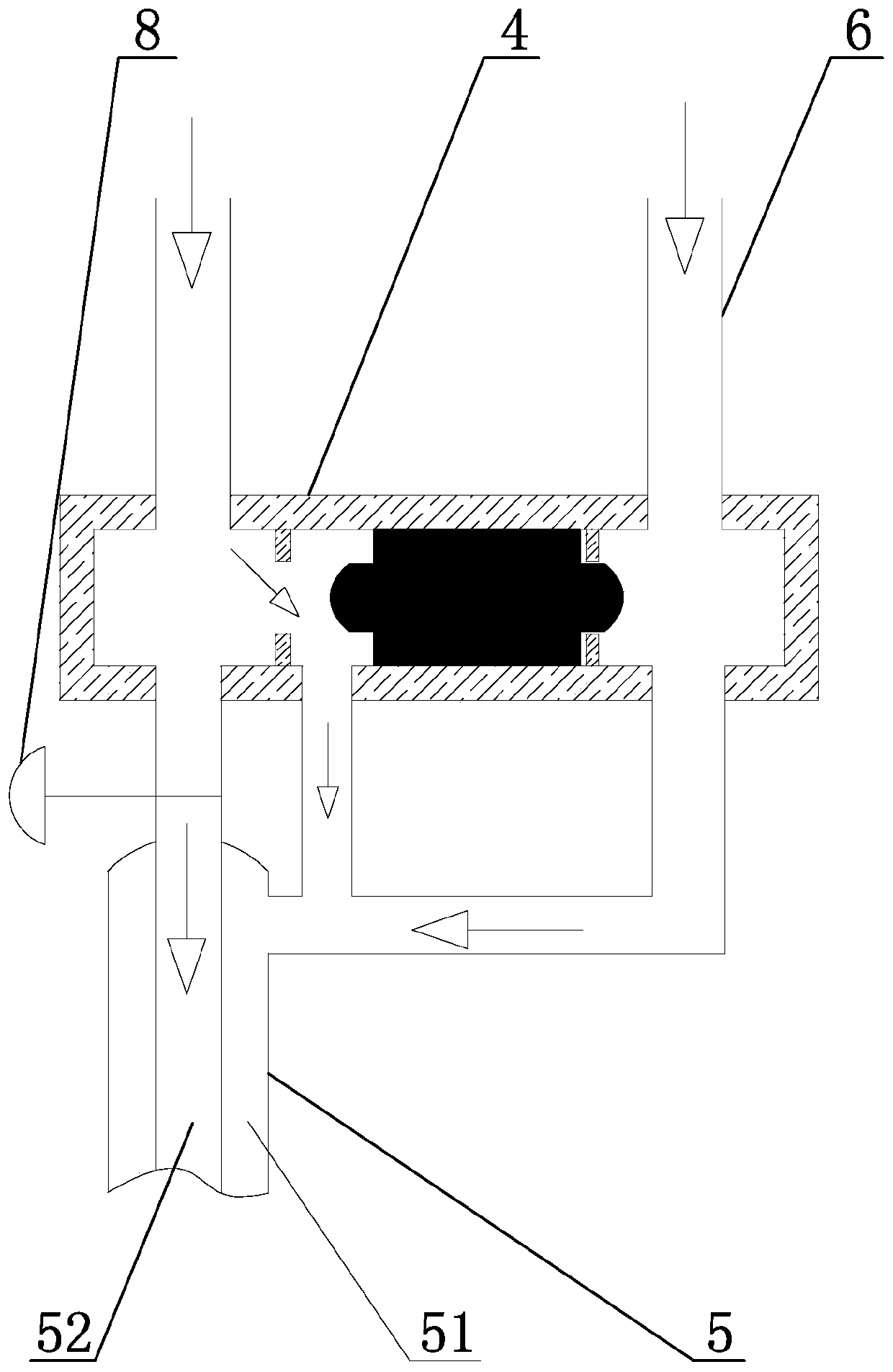

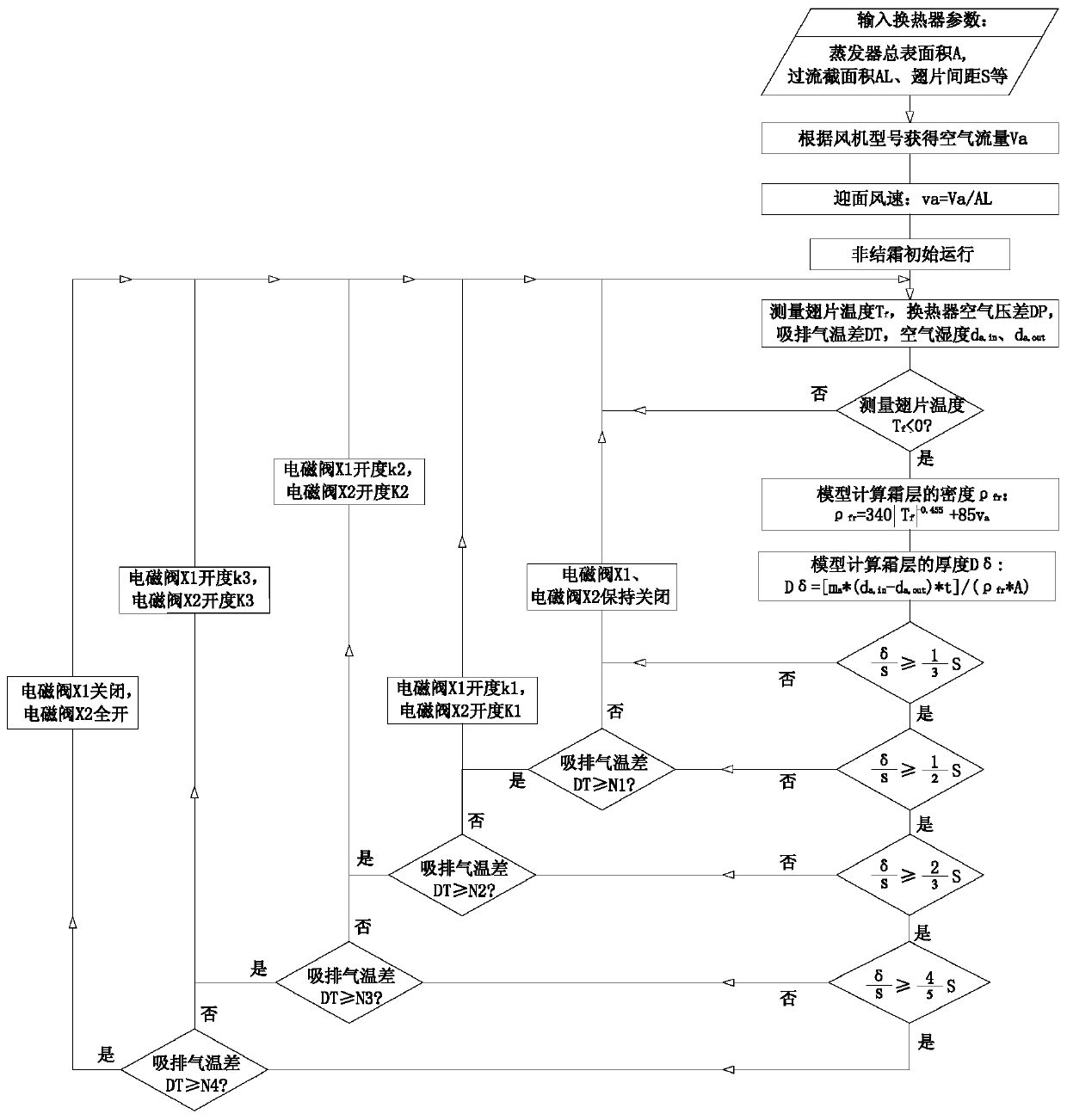

[0051] see Figure 1-Figure 3, the heat pump system has a main cycle and a defrosting branch, and the main cycle along the refrigerant flow direction mainly includes: compressor 1, condenser 2, throttling device 3, converter 4 and casing evaporator 5, condenser 2 are respectively connected with the compressor 1, the throttling device 3 and the inverter 4, the inverter 4 is respectively connected with the throttling device 3, and the sleeve-type evaporator 5, and the sleeve-type evaporator 5 is respectively connected with the compressor 1 and the The throttling device 3 is connected; it also includes a defrosting branch 6. The defrosting branch 6 starts from the entrance of the condenser 2, passes through the converter 4 and the casing evaporator 5 in sequence, and finally converges to the front of the throttling device 3 A first temperature sensor 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com