Production process system and process flow method of PCB

A printed circuit board and production process technology, applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems that are easy to interfere and affect the cutting effect, and achieve the effect of smooth cutting process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

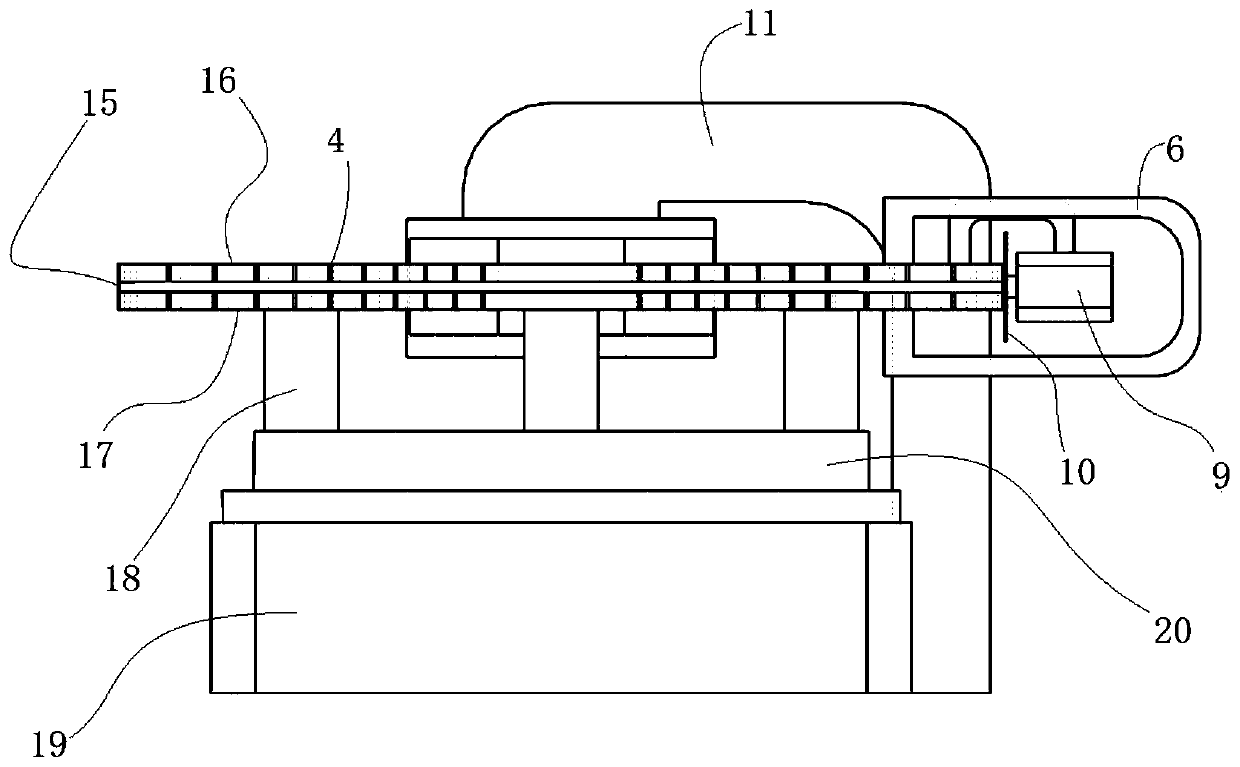

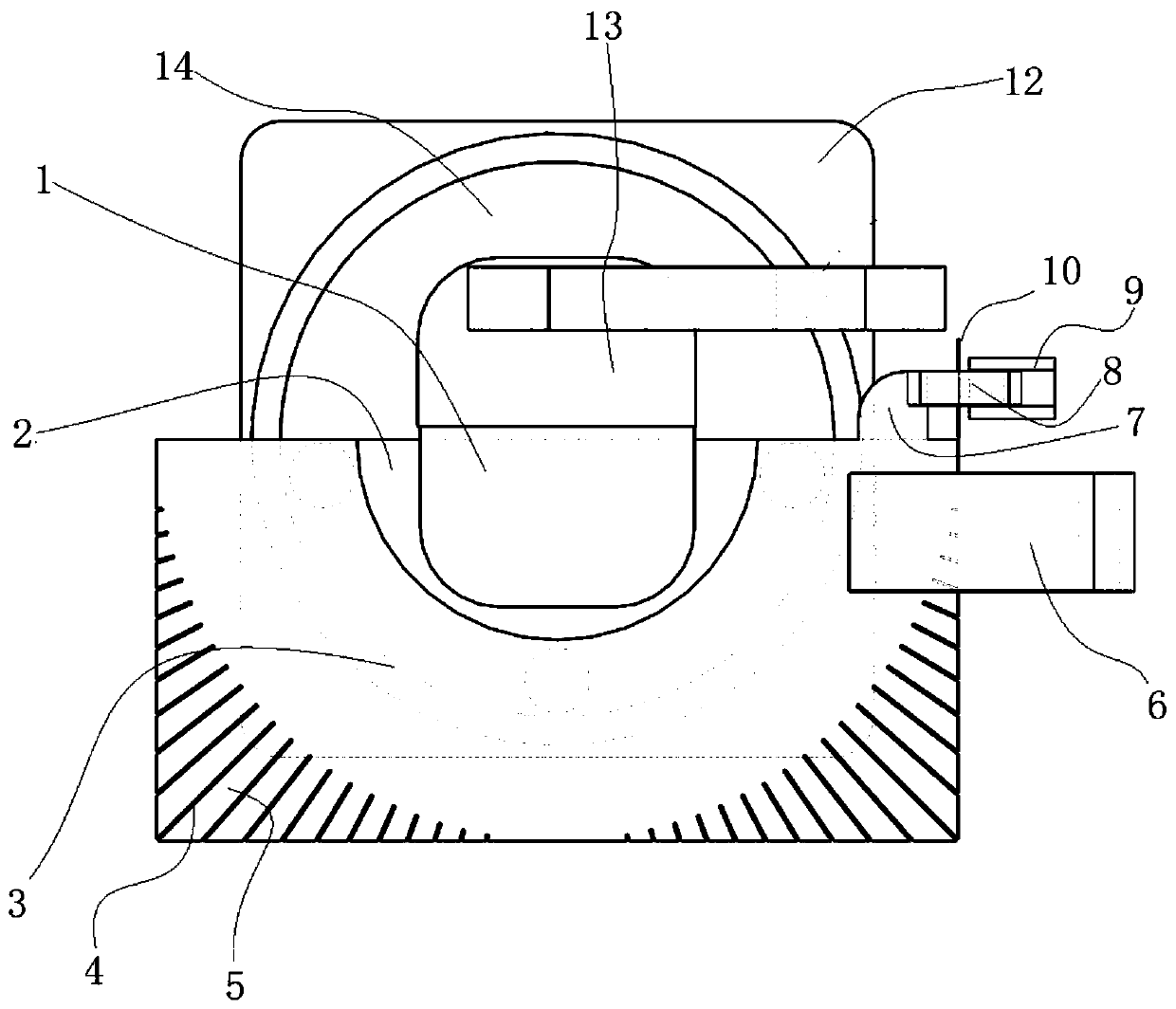

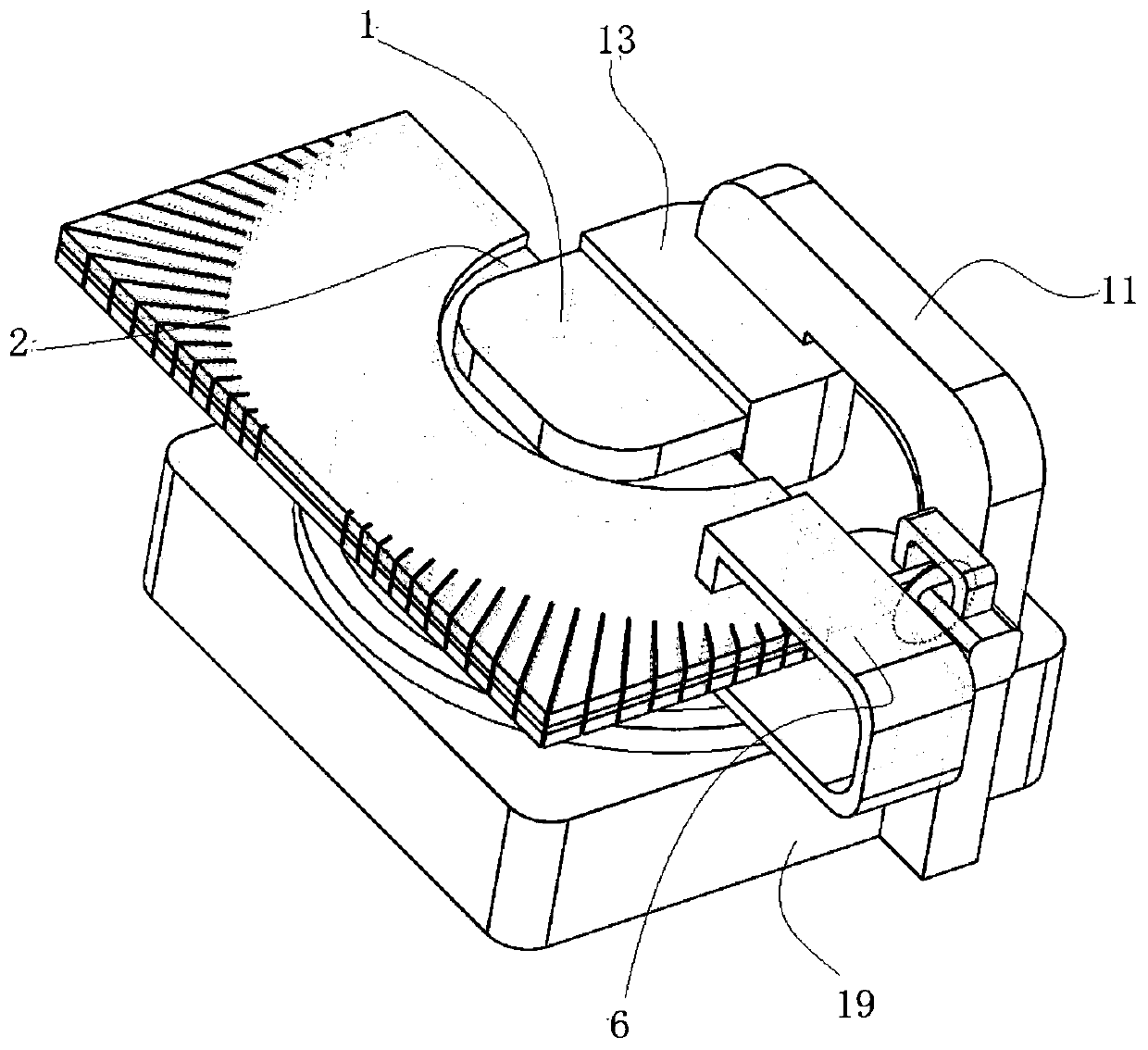

[0030] as attached Figures 1 to 12 The production process system of the shown PCB printed circuit board comprises a turntable base 19, a horizontal turntable 20 is arranged on the turntable base 19, and a driving device can drive the turntable 20 to rotate horizontally; the turntable 20 is provided with a horizontal lower rotating disk 17, and the lower rotating disk 17 is supported on the rotating table 20 by a plurality of support columns 18, and the rotation of the rotating table 20 can drive the lower rotating disk 17 to rotate synchronously. ;

[0031] The top of the lower rotating disk 17 is horizontally provided with an upper rotating disk 16; the upper rotating disk 16 is fixedly supported and connected with the lower rotating disk 17 through the U-shaped support arm 6; the upper rotating disk 16 is connected with the lower rotating disk A gap layer 26 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com