Control system for a rotary milking parlour and method of controlling a rotary milking parlour

A control system and milking parlor technology, applied in applications, animal houses, animal husbandry, etc., can solve problems such as safety layout errors, and achieve the effect of robust design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

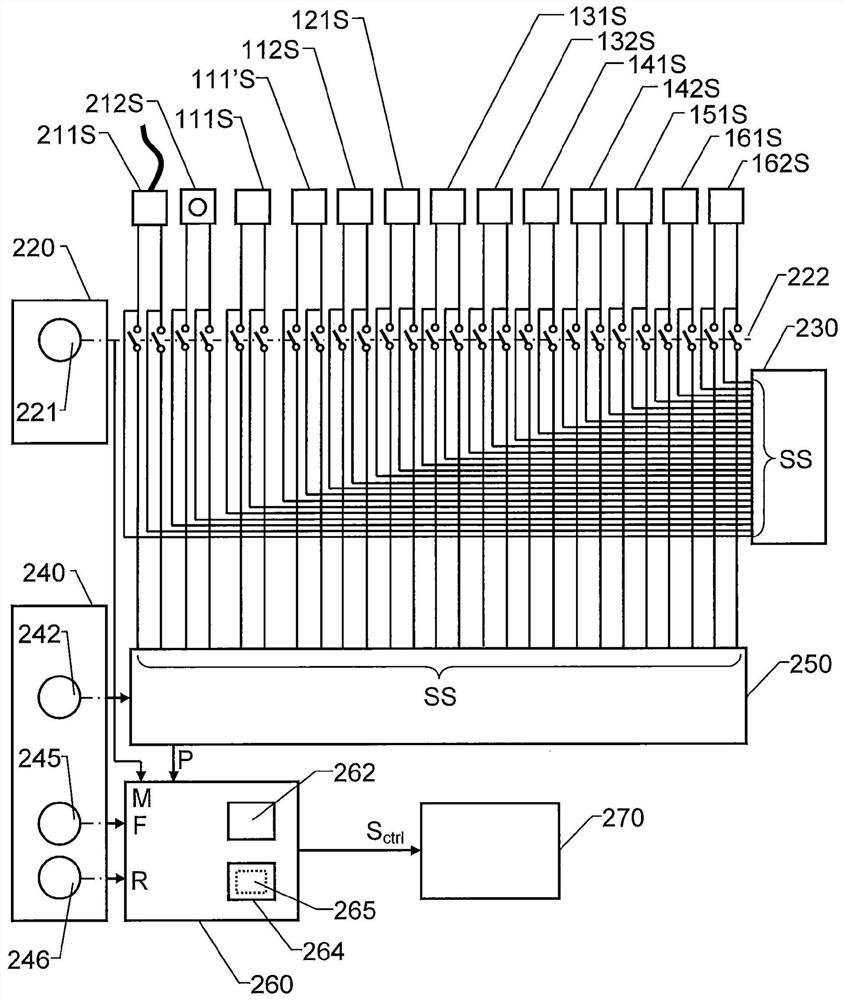

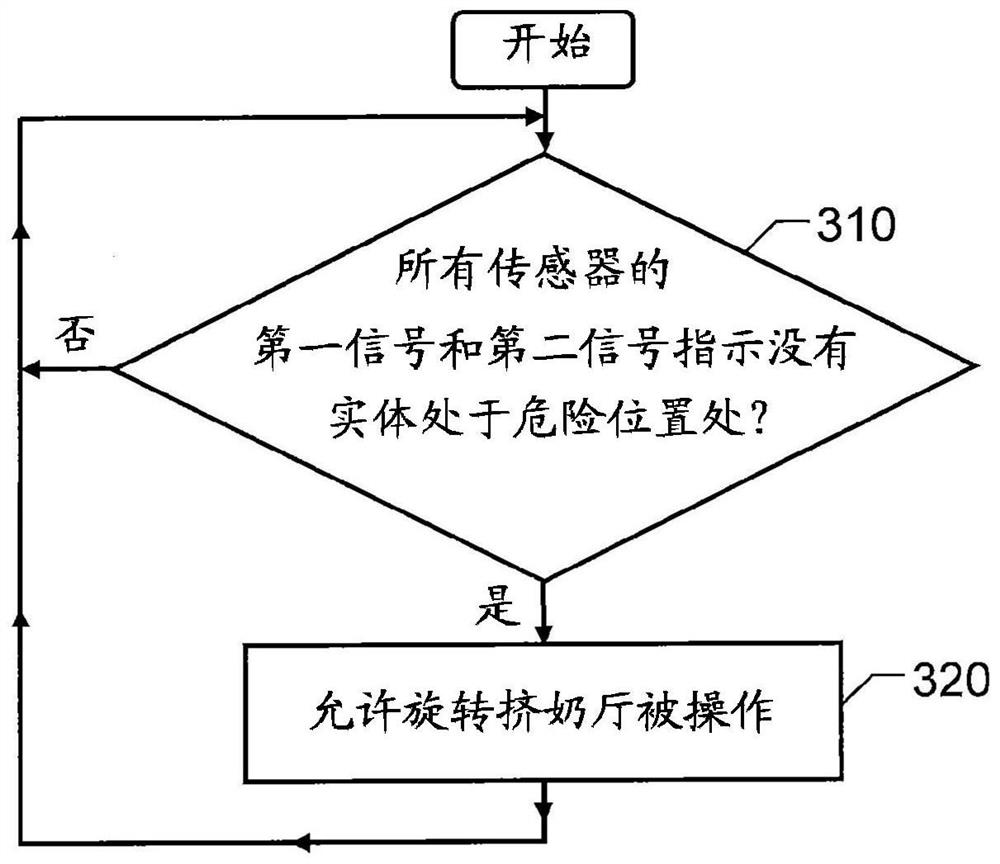

[0029] figure 1 show an example of a rotary milking parlour 100 that can be controlled by the present invention, and figure 2 A block diagram of a system according to one embodiment of the invention is shown.

[0030]The rotating milking parlour 100 is associated with an entry area 110 through which the animals A to be milked can enter the platform 105 of parlor E 100 . The rotary milking parlour 100 is also associated with an exit area 120, where animal A leaves the X-platform 105 after finishing milking. Downstream of the entry zone 110 (with respect to the forward rotation direction RF), a first operator zone 130 is arranged. The first operator zone 130 enables the operator H to prepare the animal A for milking and to manually attach the teat cups of the milking machine. The second operator area 140 is arranged upstream of the exit area 120 . Here, operator H releases teat cups from animal A and performs various post-milking treatments. Platform 105 is generally of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com