Steel wire rope strapping machine facilitating rope disengaging

A wire rope and strapping machine technology, applied in the field of wire rope, can solve the problems of wire rope disorder, low production efficiency, inconvenient bundling, etc., and achieve the effect of preventing disorder and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

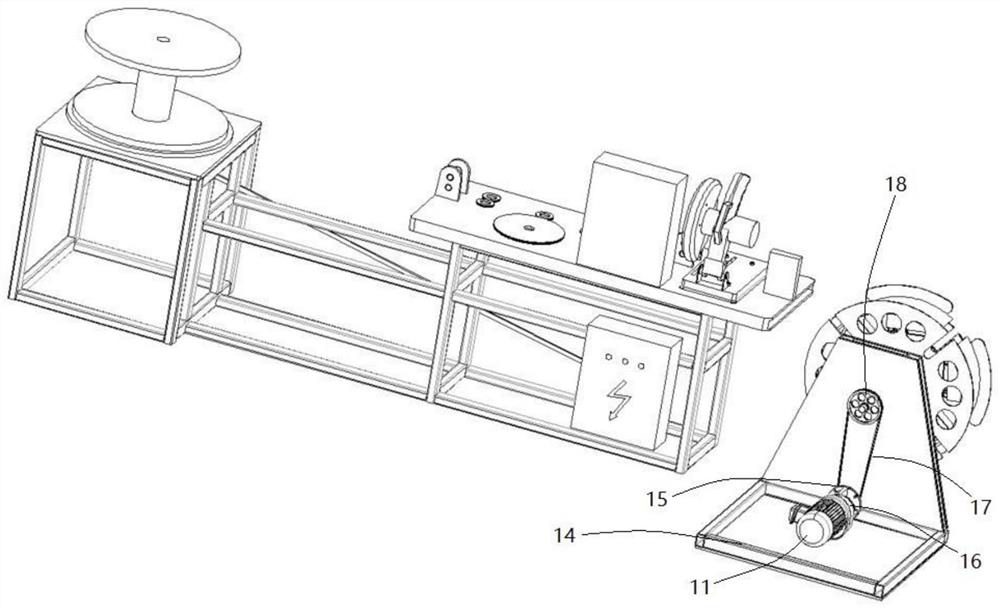

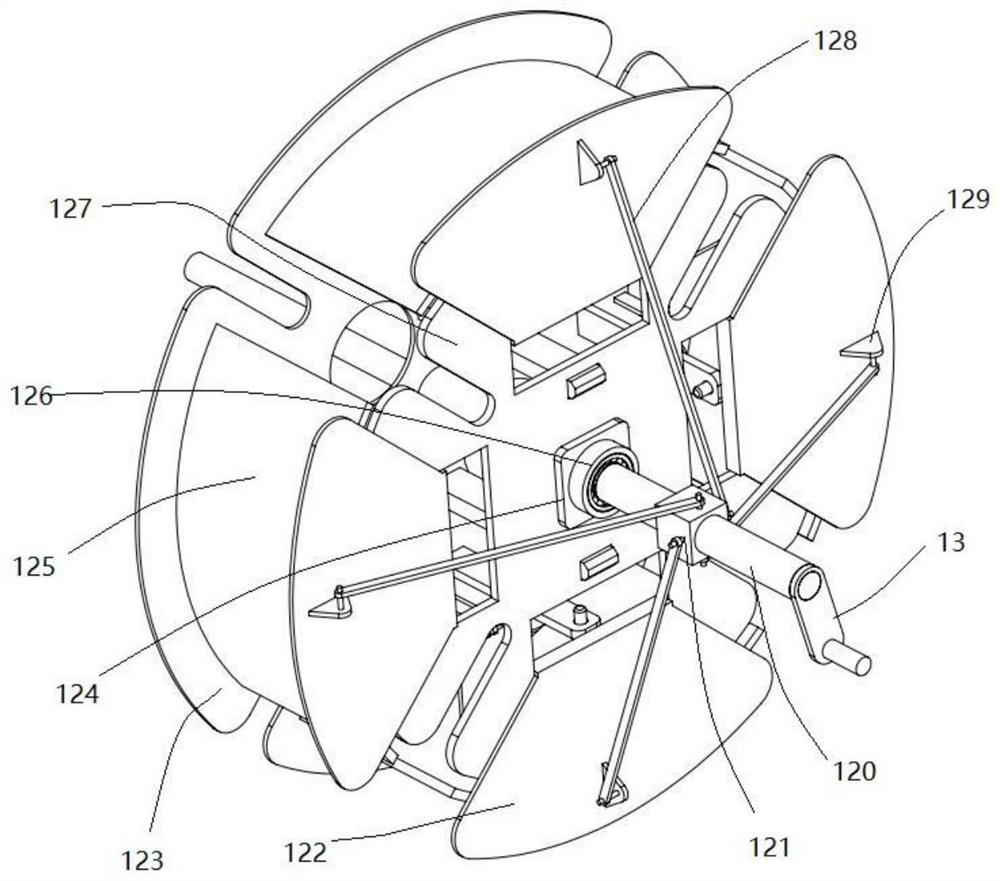

[0025] 1. If Figure 1-9 As shown, this embodiment discloses a wire rope binding machine that is easy to take off the rope, including a workbench 1, a turntable 3 arranged on the workbench 1, a rope guide tube 5, a guide wheel 6, a counting disc 7, and a cutting device 9 and the high-frequency heating device 10 arranged on the workbench 1, the side end of the workbench 1 is provided with a brake device 4, and bundled steel wire ropes are placed on the turntable 3; the motor support 14 is arranged on the workbench On the binding mechanism at the front end of the platform 1, the motor 11 is installed on the motor support 14, and a reducer 16, a small pulley 15, a belt 17, and a large pulley 18 are respectively connected to the motor 11 in sequence; The whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com