Motorcompressor unit with variable aerodynamic profile

A technology of electric compressors and compressors, applied in engine manufacturing, machines/engines, liquid fuel engines, etc., can solve problems such as limiting the application range of compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

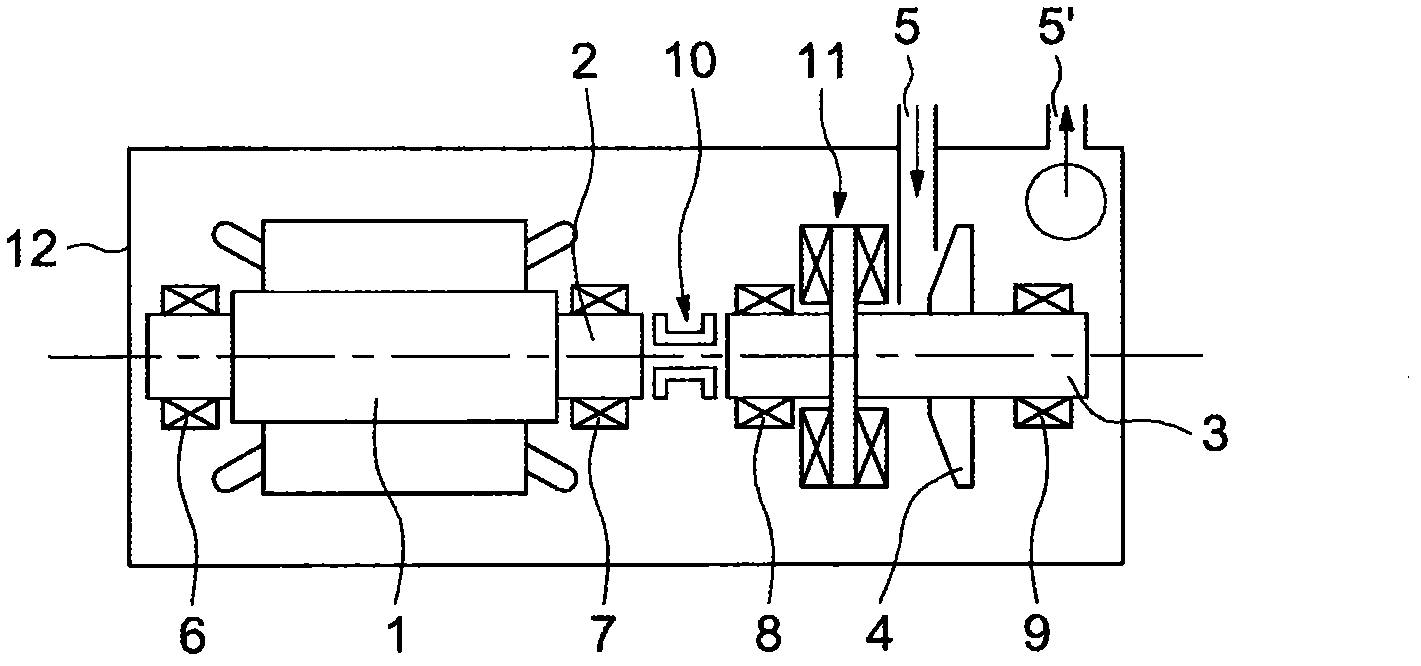

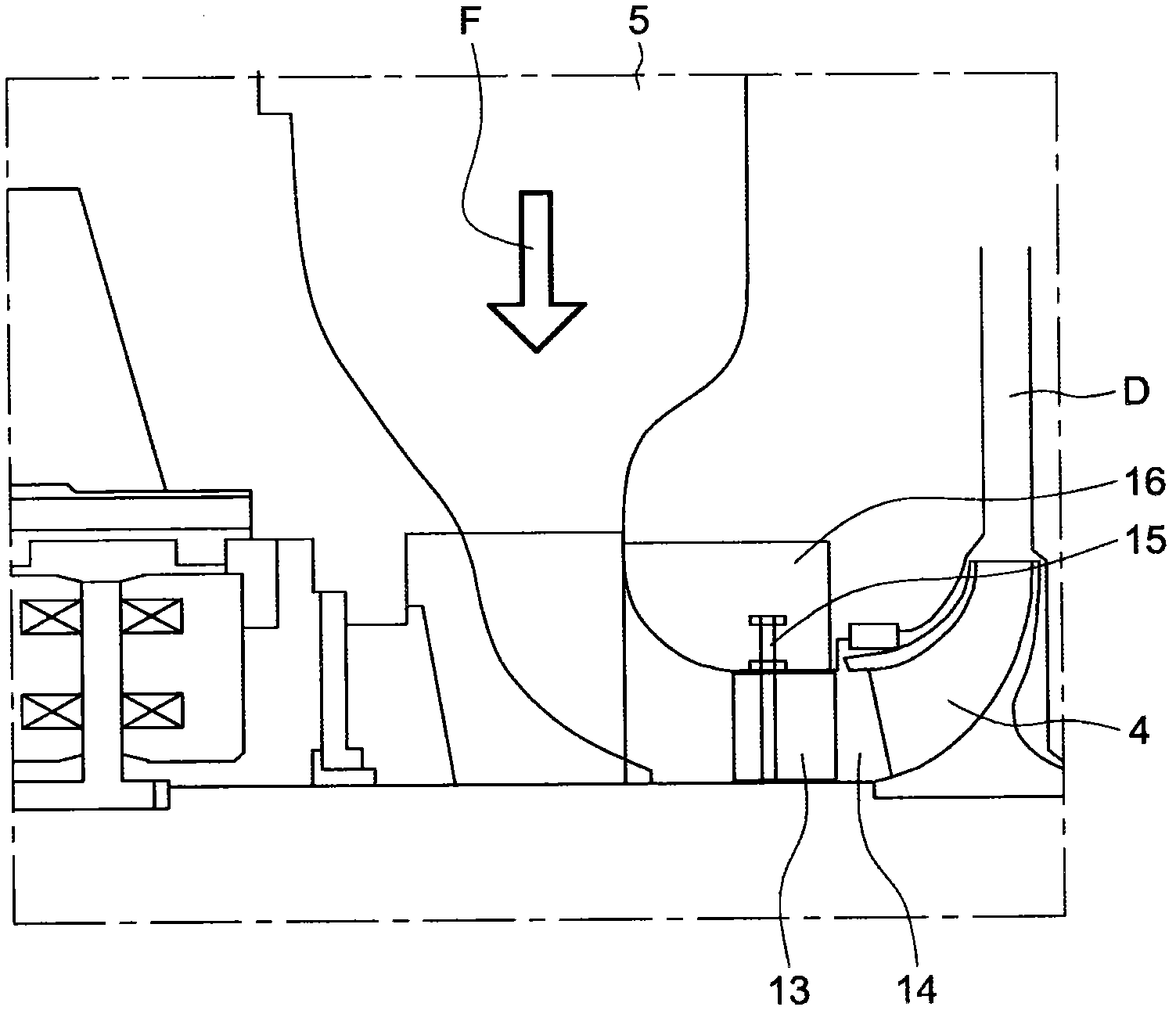

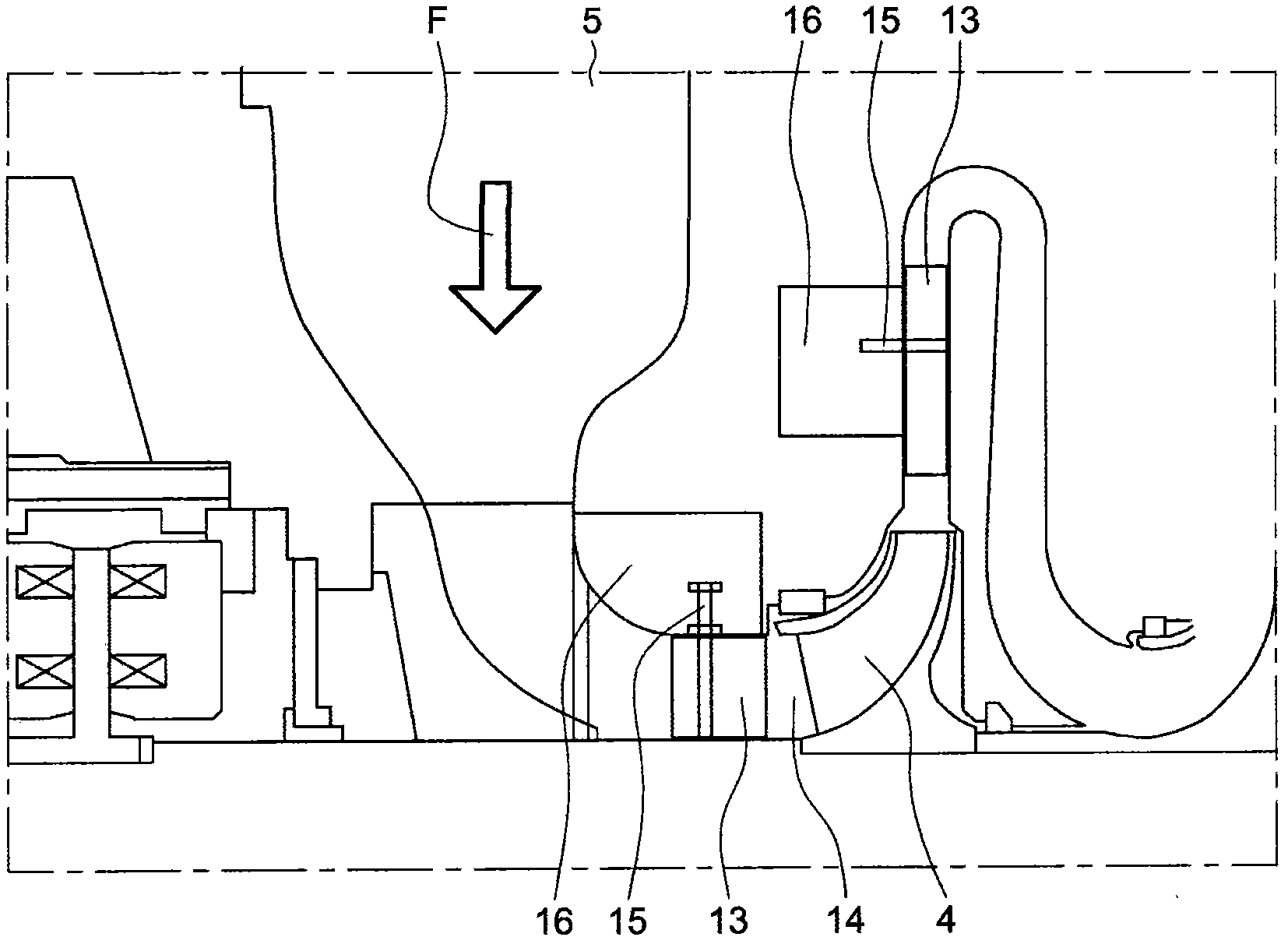

[0024] exist figure 1 The motor-compressor unit illustrated in , basically comprises an electric motor 1 , including for example a variable speed motor that drives in rotation a rotor 2 , which itself drives at the same speed a propeller shaft 3 , on which is fixed an impeller 4 .

[0025] It can be seen that the electric compressor unit thus comprises a single compression stage consisting of a centrifugal impeller 4 which sucks in the gas released from the supply pipe 5 to increase its pressure and deliver it to the outlet 5'.

[0026] In the described embodiment, the rotor 2 is supported by two end bearings 6 and 7 . The same applies to the housing of the transmission shaft 3 , which is likewise supported by two end bearings 8 and 9 . Thus, with such an arrangement, the rotor 2 and the propeller shaft 3 are connected by the flexible coupling 10 .

[0027] However, even if the rotor and drive shaft are connected by a fixed coupling, it still does not depart from the scope o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com