Three-axis rapid sorting robot system

A robot system and robot technology, applied in the field of robots, can solve the problems of reduced sorting speed, poor independence of the sorting system, and poor carrying capacity of the sorting system, so as to increase the sorting load, realize assembly and disassembly, and reduce load impact. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiment:

[0020] A three-axis rapid sorting robot system including a modular frame, conveyor assembly, parallel robot and vision system;

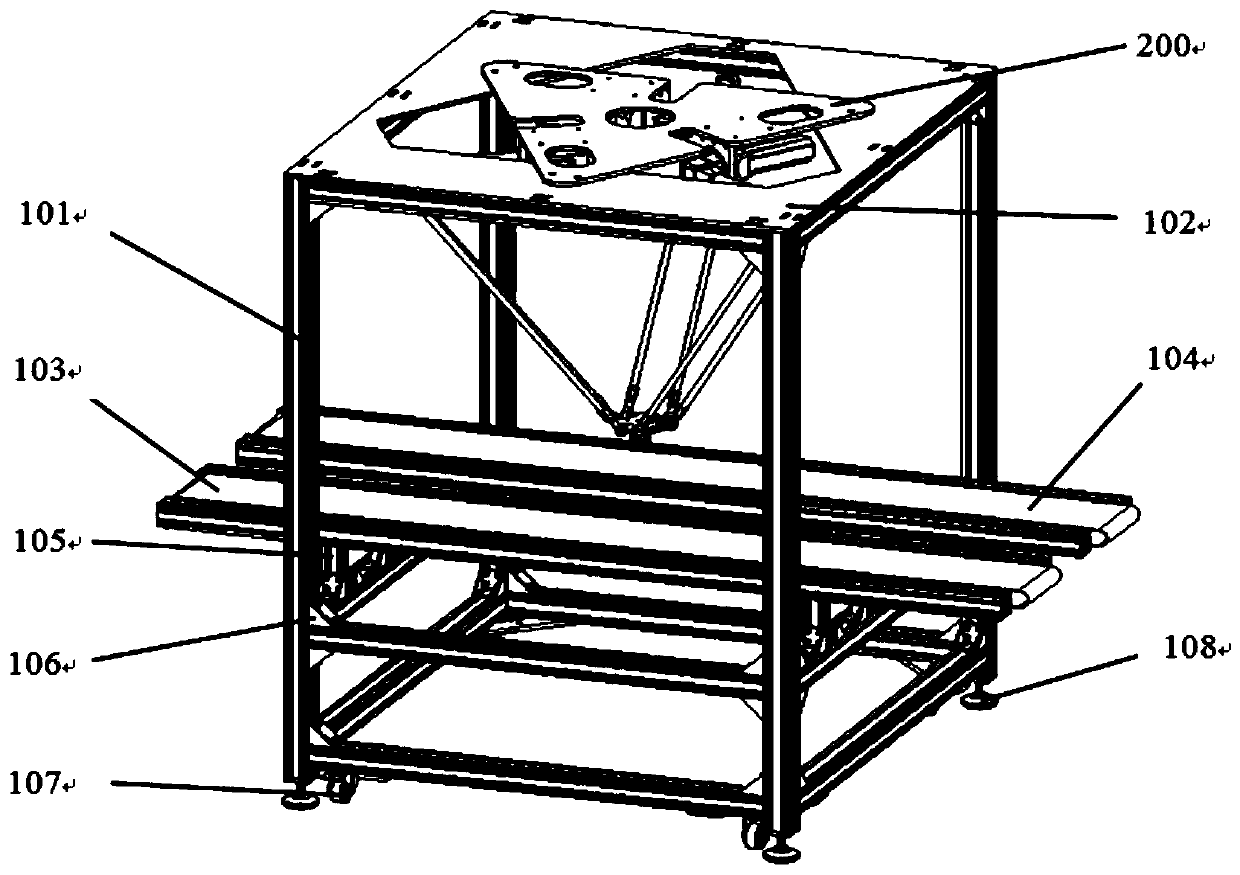

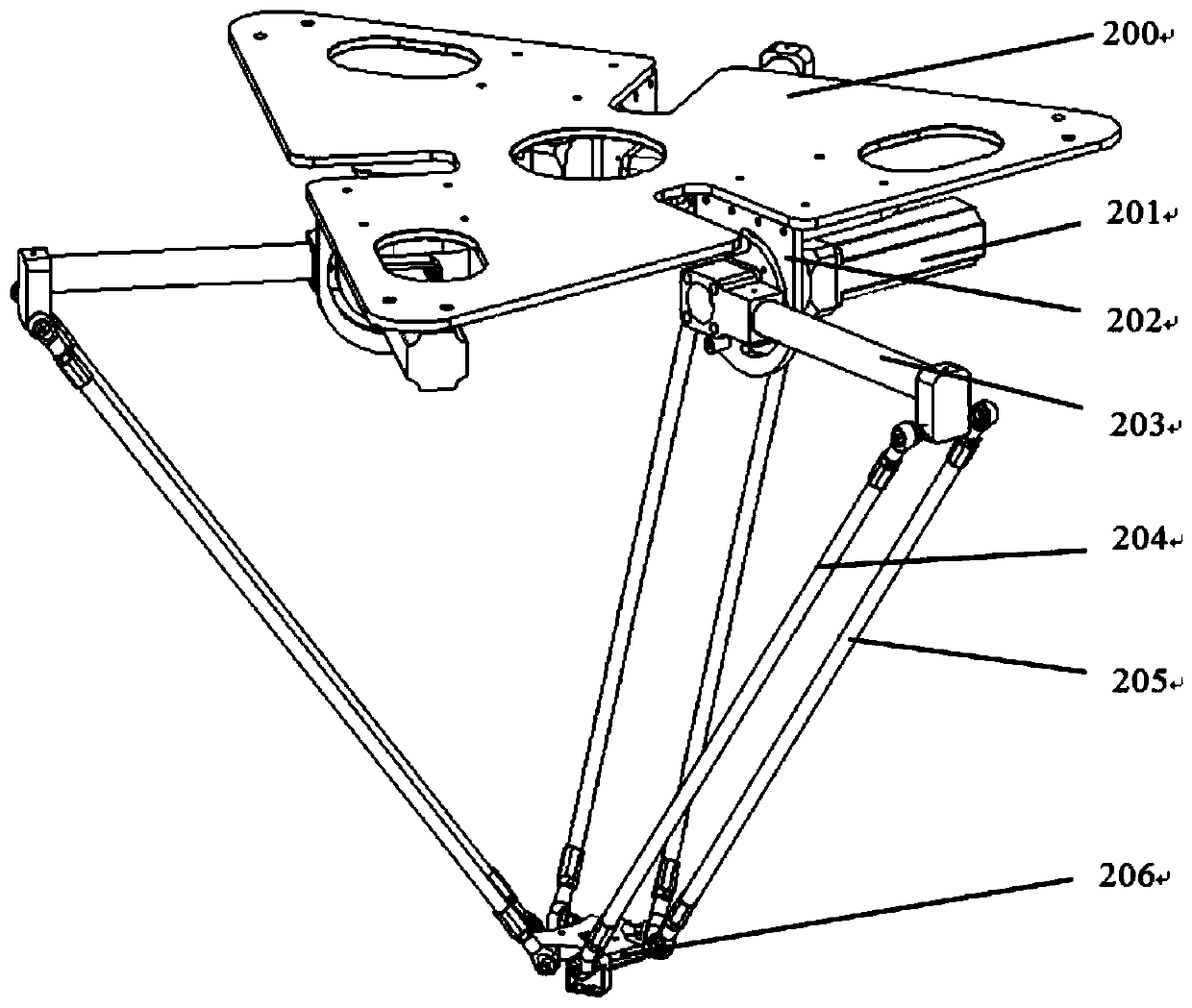

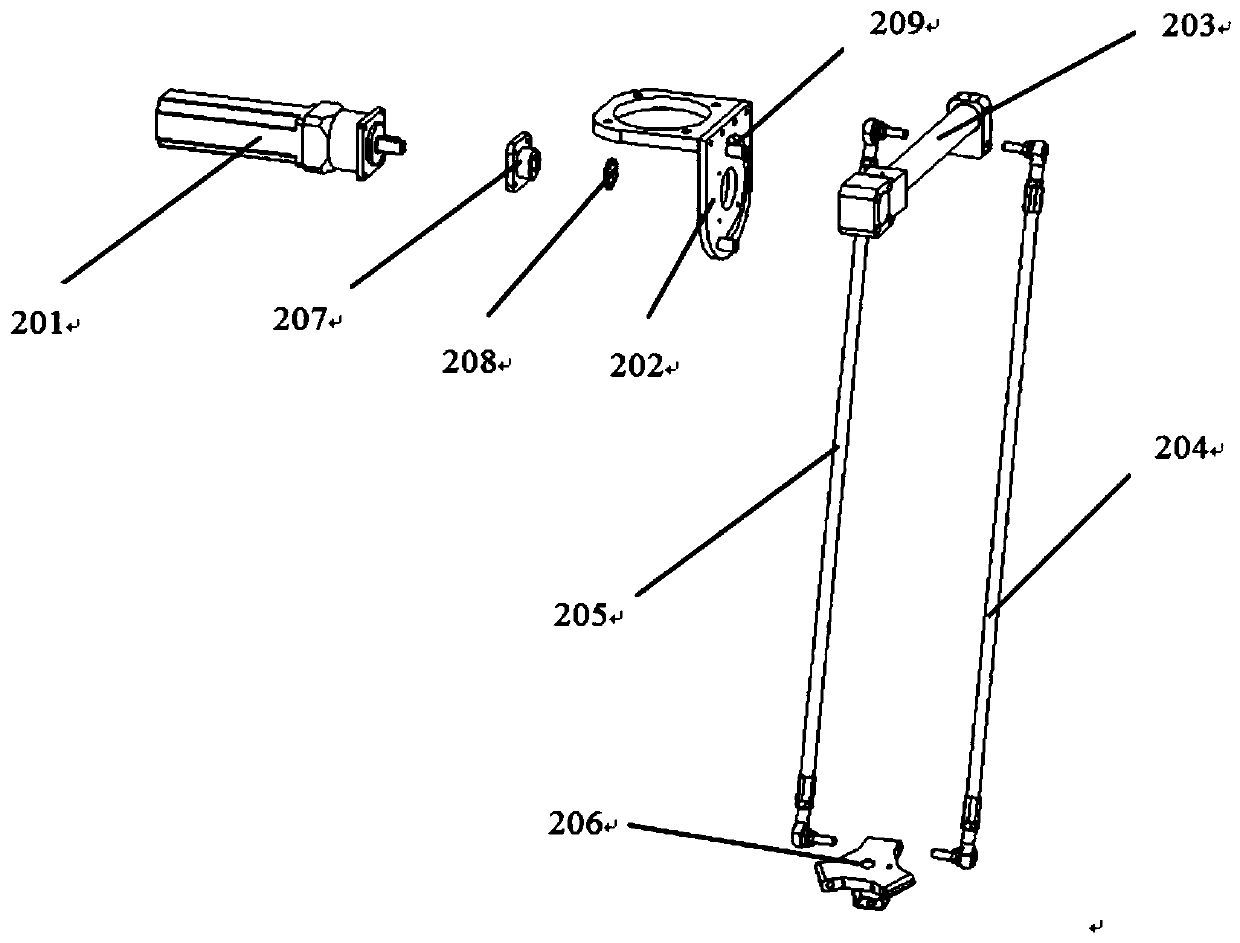

[0021] Such as figure 1 As shown, the modular frame includes a bed, a fixed top plate 102, a support rod 105, a triangular connector 106, rollers 107, and feet 108; the bed is built by profiles 101, and the profiles 101 are connected by triangle Part 106 is screwed; the lower end of the support rod 105 is fixed to the bed by the triangular connector 106, and the upper end is screwed to the conveyor belt assembly for supporting and fixing the conveyor belt assembly; the rollers 107 and anchors 108 are respectively screwed to the bottom of the bed The four corners of the end, the roller 107 is located inside the foot 108, the foot 108 can be adjusted up and down, used to level the bed, the roller 107 has a locking device; when the bed needs to be mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com