Portable aluminum material cutting machine with cutting angle adjusting function

A technology of cutting angle and cutting machine, which is applied in the direction of manufacturing tools, large fixed members, metal processing machinery parts, etc., can solve the problems of reducing the practicality of cutting machines, reducing the convenience of blades, and the single shape of aluminum materials, so as to improve the convenience , simple structure, and the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

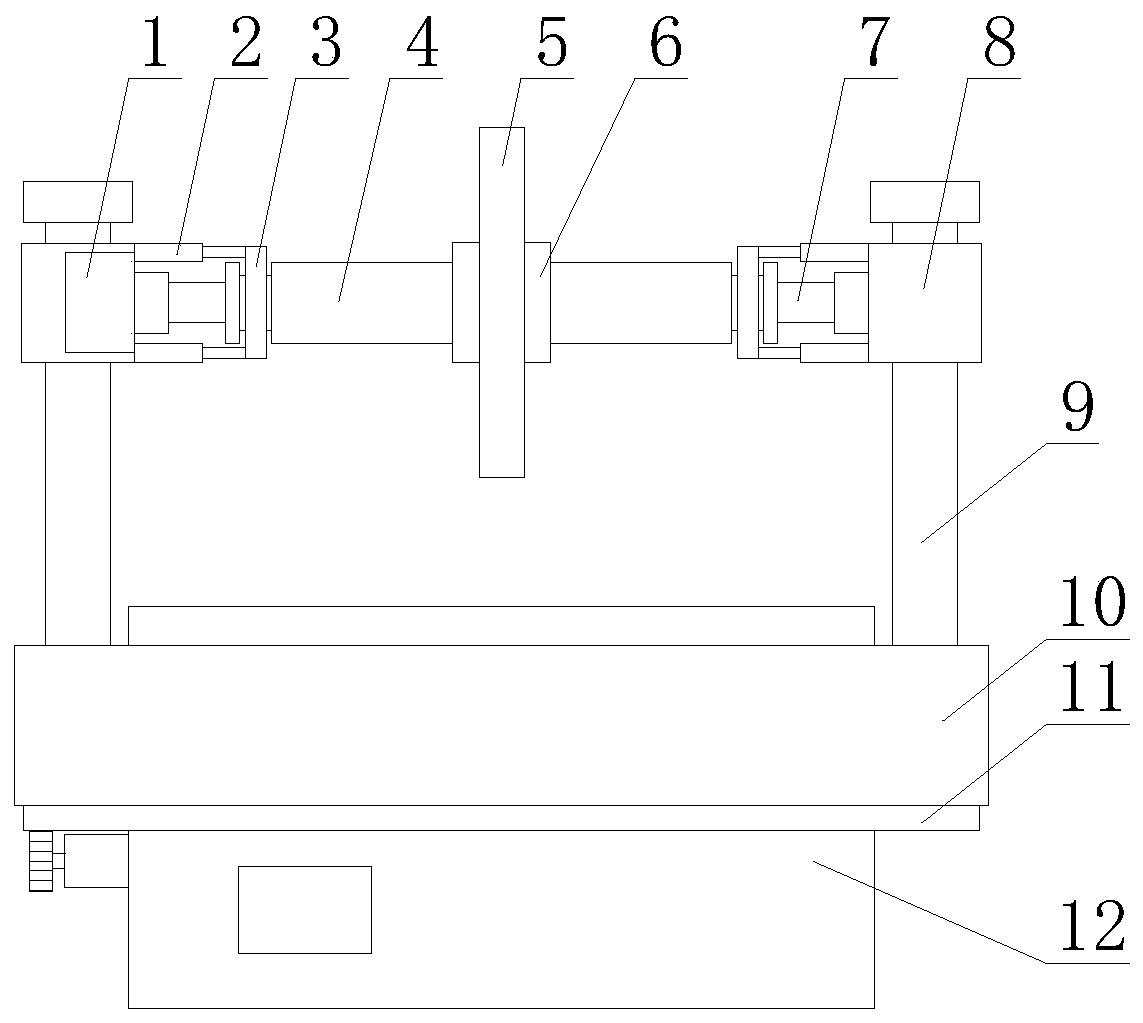

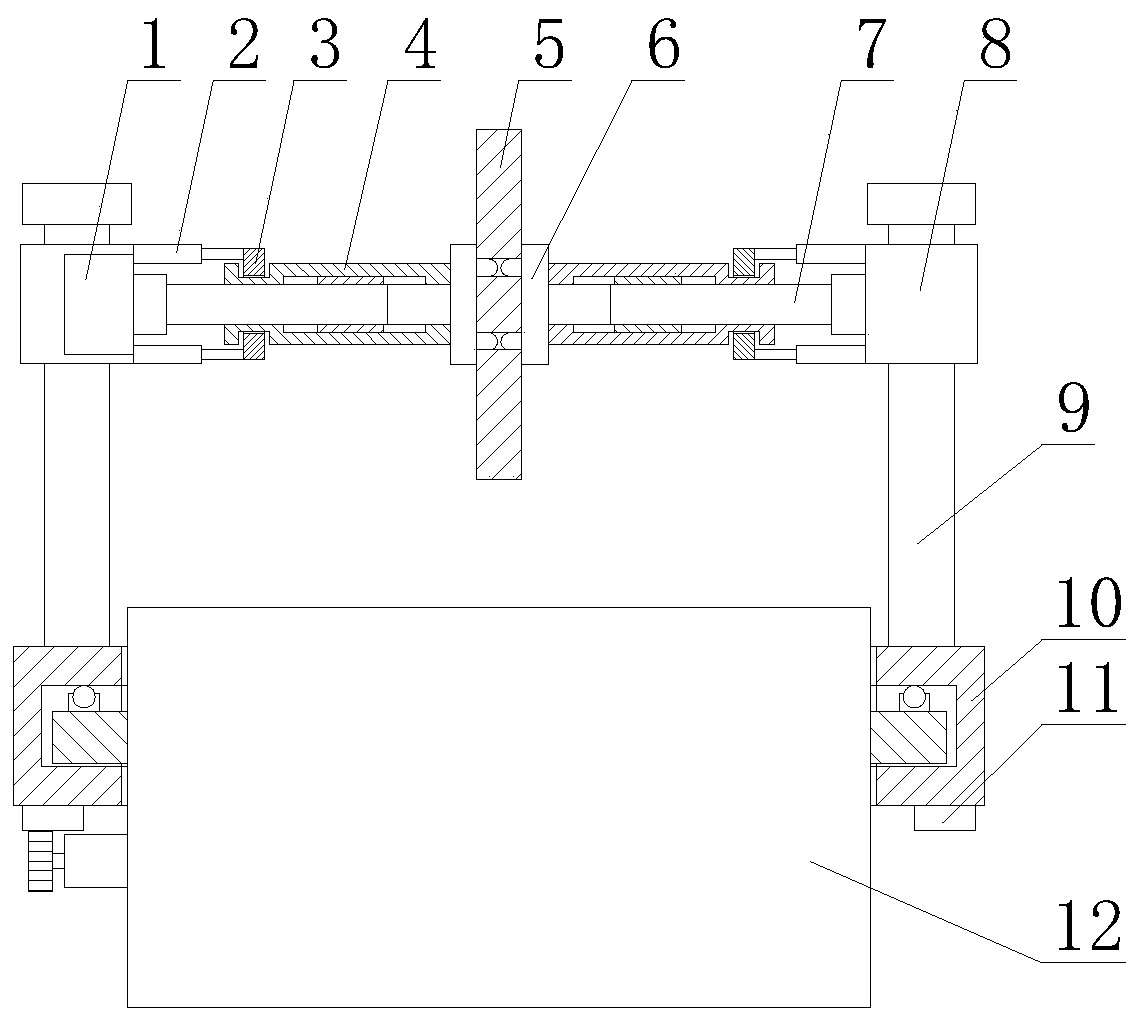

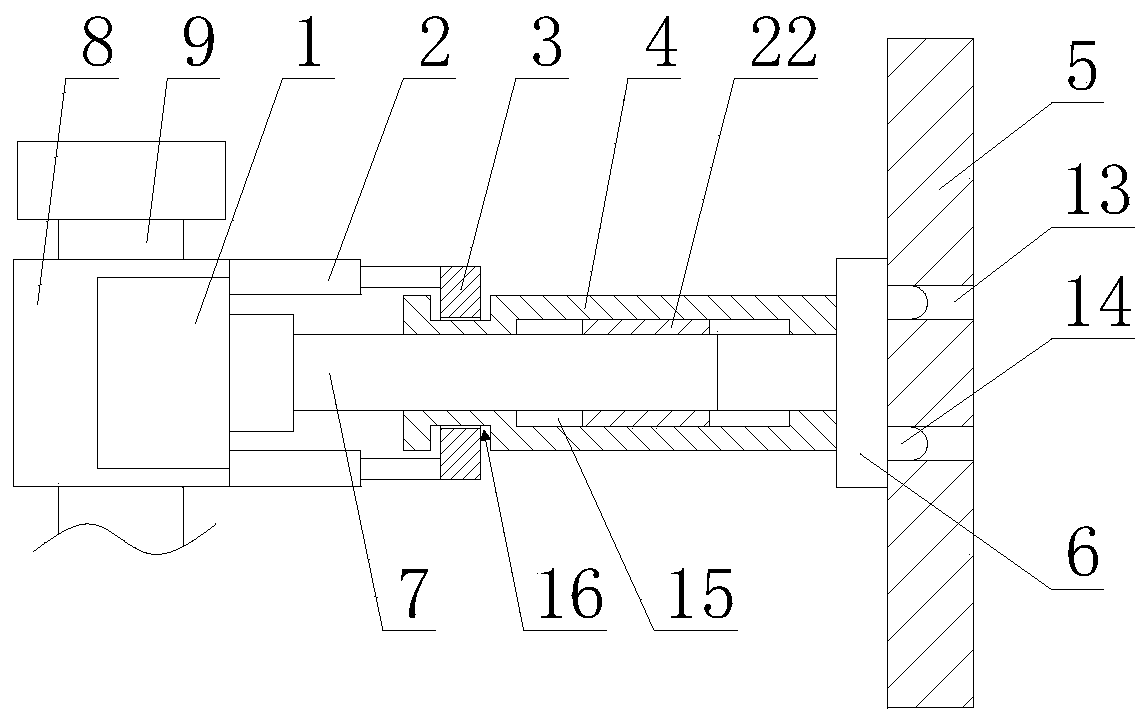

[0024] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0025] Such as Figure 1-2 As shown, a convenient aluminum cutting machine with a cutting angle adjustment function includes a blade 5 and a base 12. The base 12 is cylindrical in shape, and also includes a steering mechanism and two replacement mechanisms. The steering mechanism is set On the base 12, the blade 5 is connected to the steering mechanism through two replacement mechanisms, and the two replacement mechanisms are symmetrically arranged with respect to the blade 5;

[0026] The angle of the blade 5 can be adjusted through the steering mechanism, so that the blade 5 can cut from different angles according to requirements, which improves the practic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com