High-precision laser cutting device

A laser cutting, high-precision technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inaccurate focus, deformation of thin plate-shaped workpieces, etc., to achieve the effect of improving accuracy and avoiding permanent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

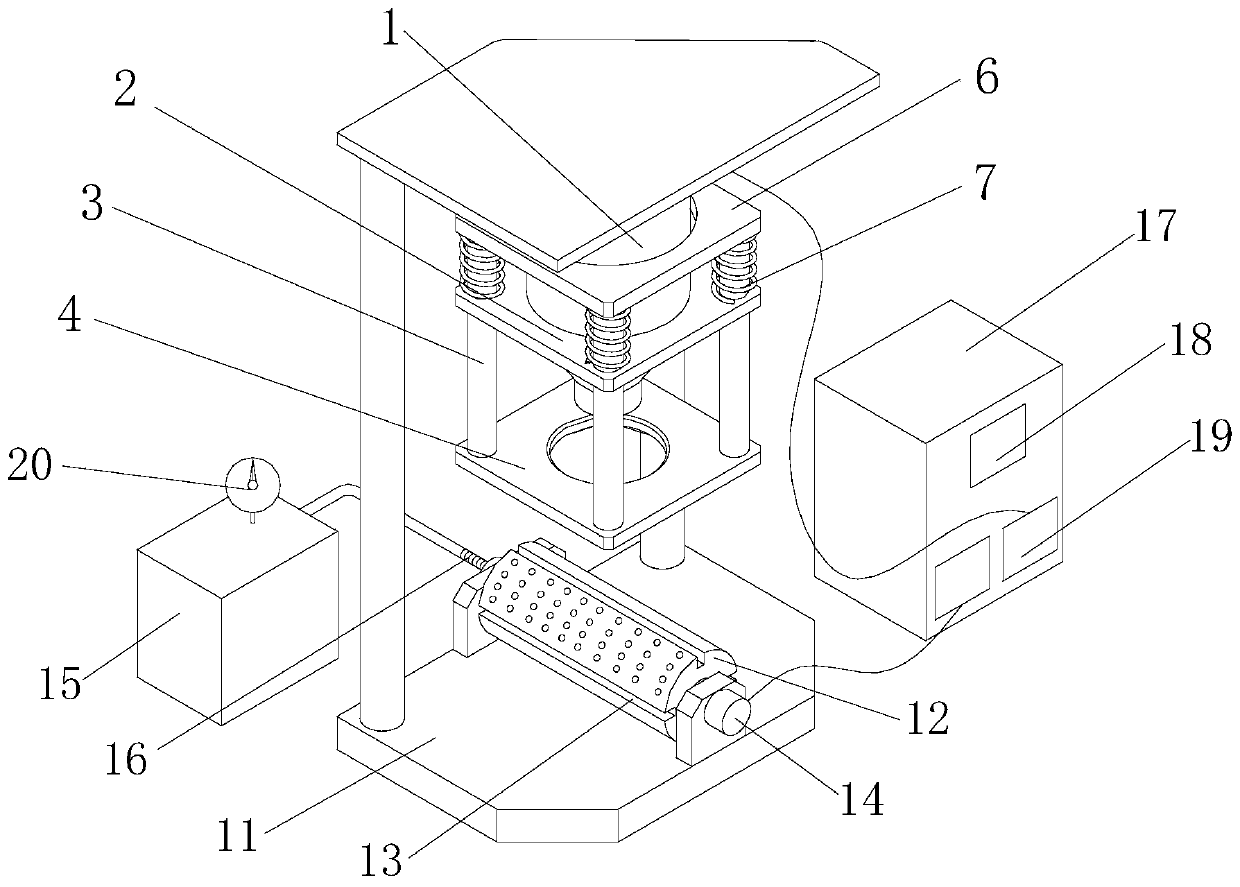

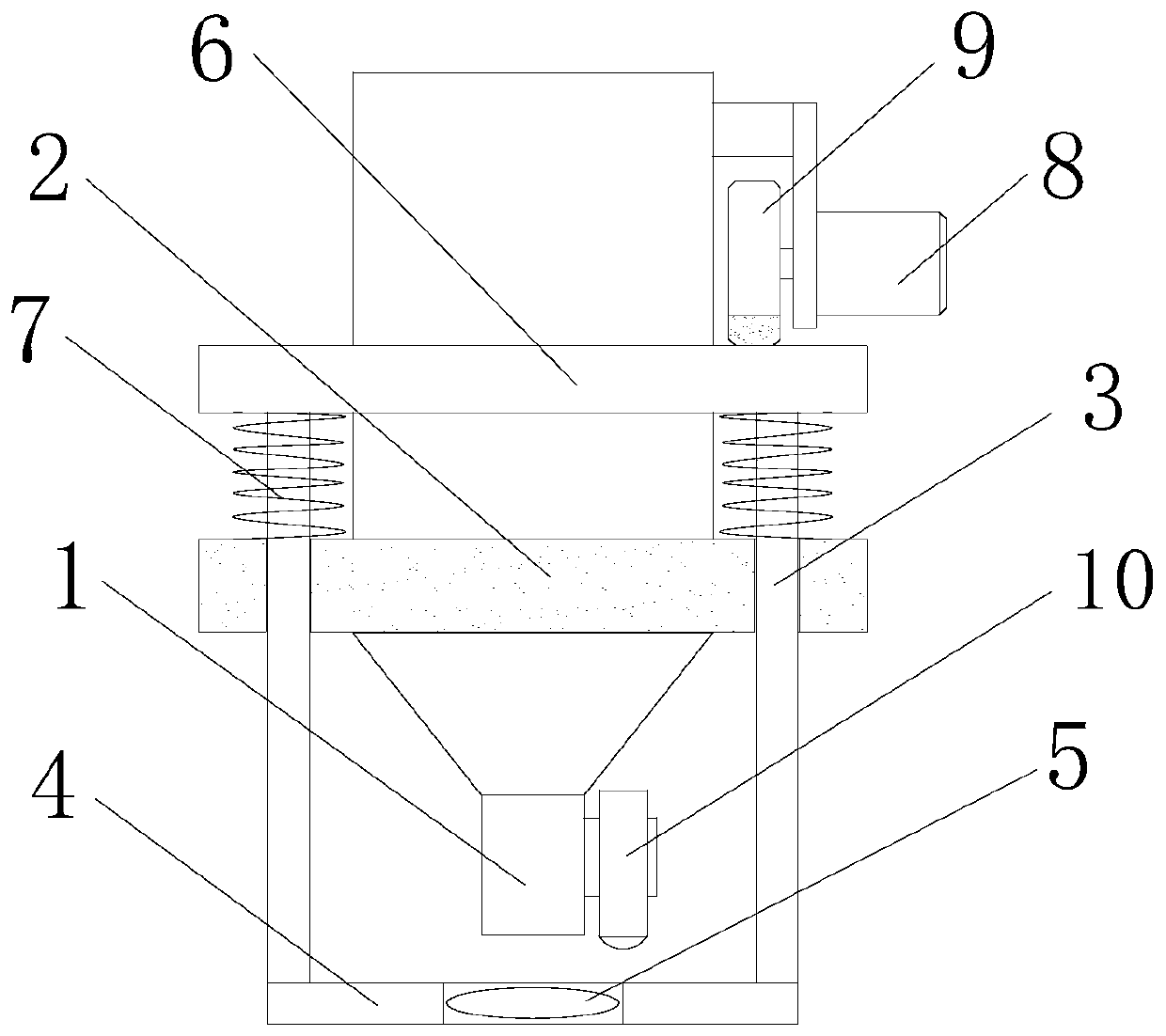

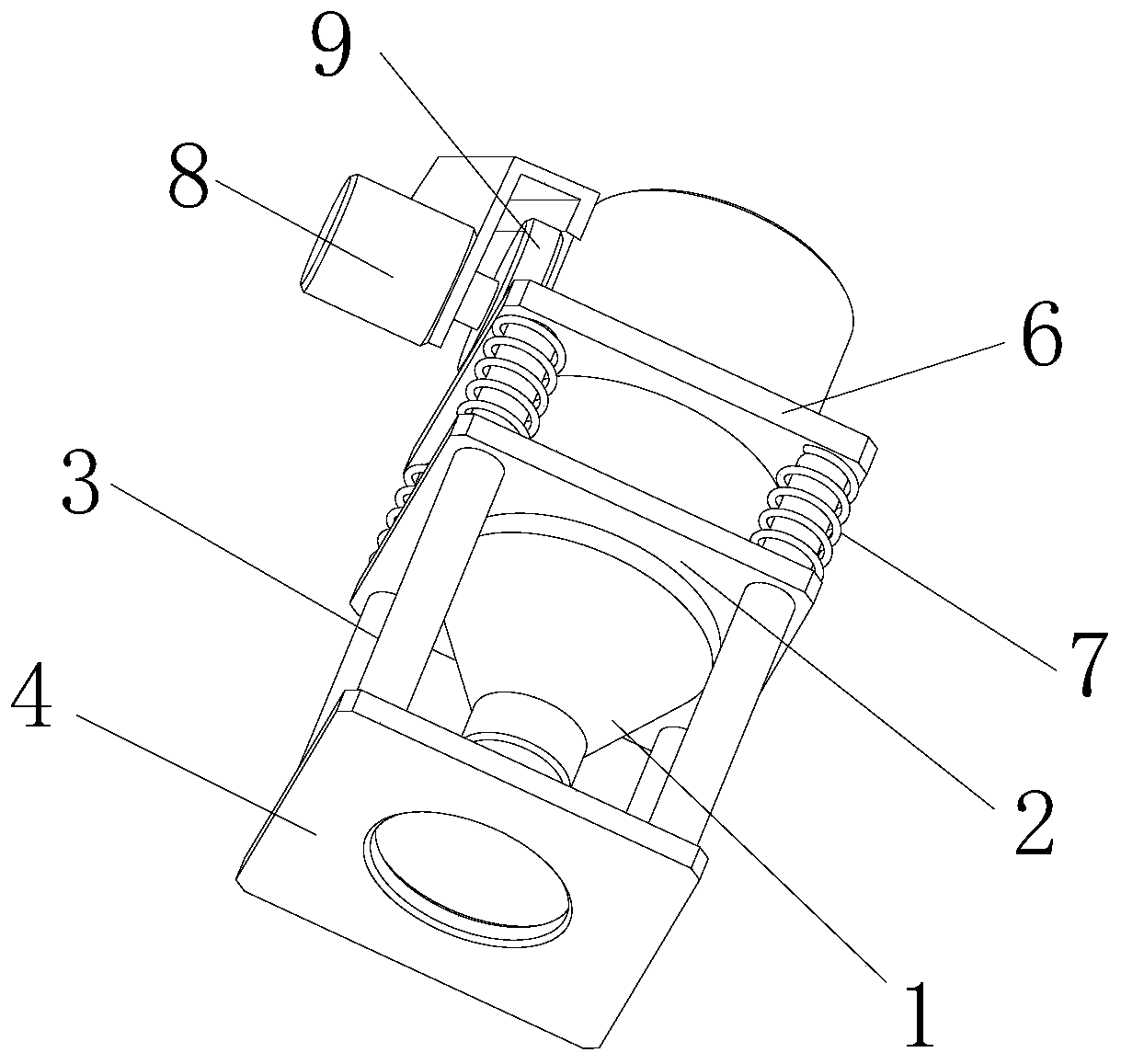

[0025] see Figure 1-3 , the present invention provides the following technical solutions: a high-precision laser cutting device, including a laser emitting head main body 1 and a focusing plate 4, the laser emitting head main body 1 is a cylindrical structure, and the bottom end of the laser emitting head main body 1 is socketed and fixed with Guide bracket plate 2, four guide rods 3 are embedded in the side of guide bracket plate 2, the bottom ends of four guide rods 3 are connected with focus plate 4, and focusing lens 5 is fitted and fixed in the opening of focus plate 4, four The top of the guide rod 3 is connected with an annular pressure plate 6, and the middle parts of the four guide rods 3 are connected with springs 7 in series. One side of the top of the emitting head main body 1 is fixed with a focusing motor 8 through a bracket, and the rotating shaft of the focusing motor 8 is connected with an eccentric wheel 9. The other side is fixed with range finder 10 side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com