Single-point needle valve hot runner system

A technology of hot runner and needle valve, which is applied in the field of hot runner, can solve the problem of easy blockage of the runner hole, and achieve the effect of convenient disassembly and assembly and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

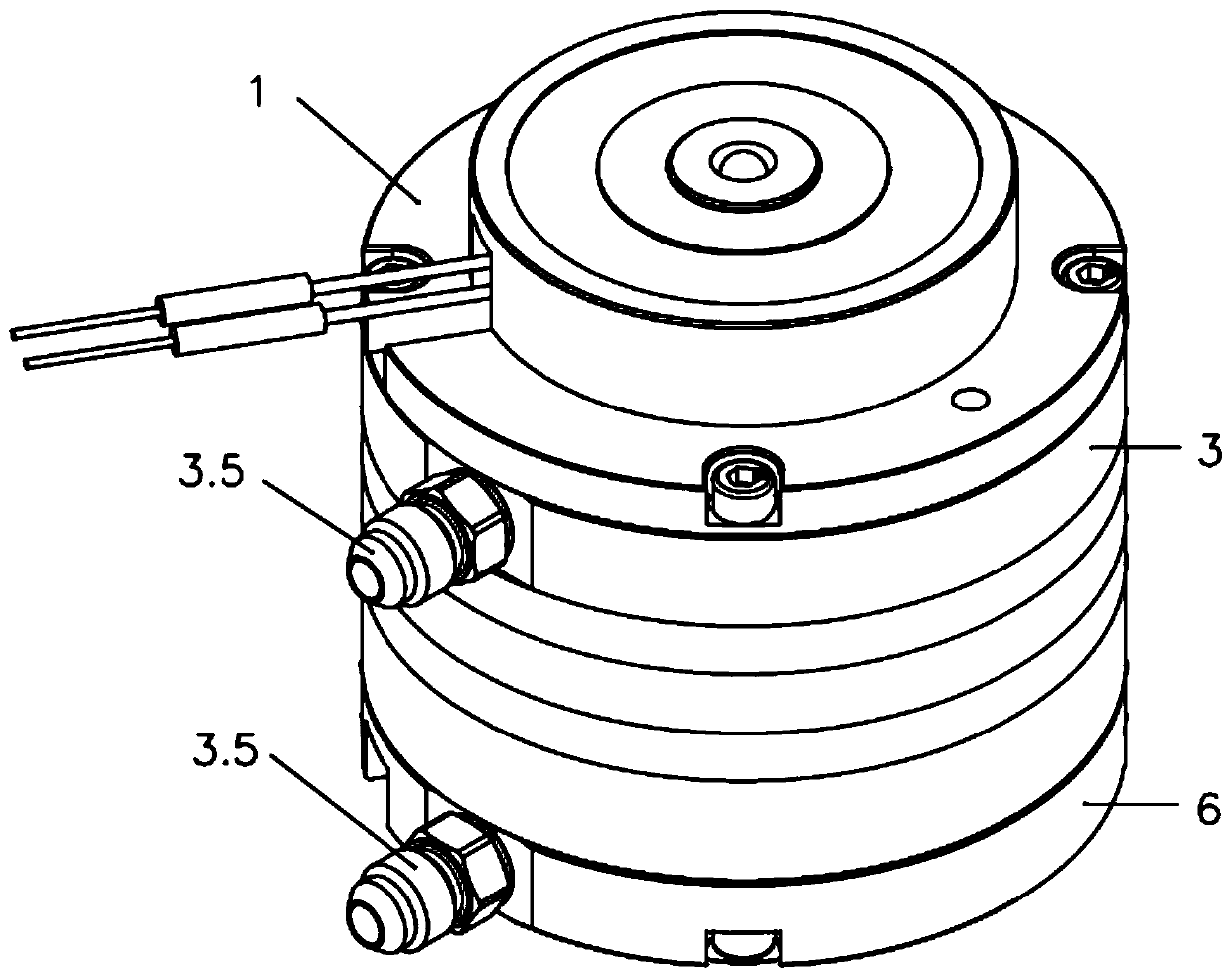

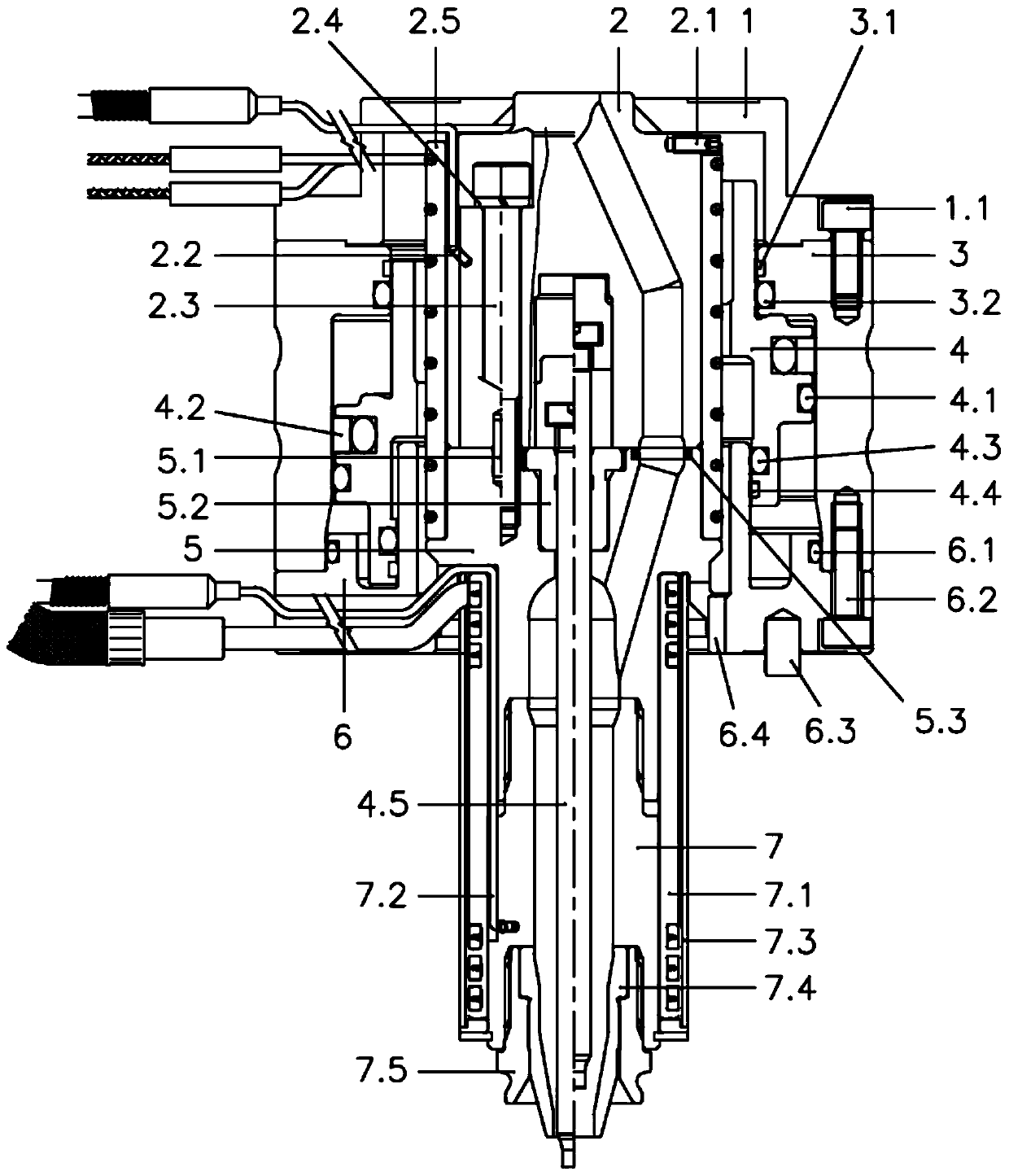

[0024] A single-point needle valve hot runner system. The single-point needle valve hot runner system includes a cylinder block 3, a piston 4, a lower body 5, an upper body 2, a lower cylinder head 6, an upper cylinder head 1, and a nozzle body 7. Among them, by increasing the gap between the lower body 5 and the accommodating cavity; increasing the gap between the upper body 2 and the accommodating cavity, the upper body heater 2.5 is provided through the upper body 2, so that the upper body heater 2.5 can be opposed to the upper body 2 and The lower body 5 is heated.

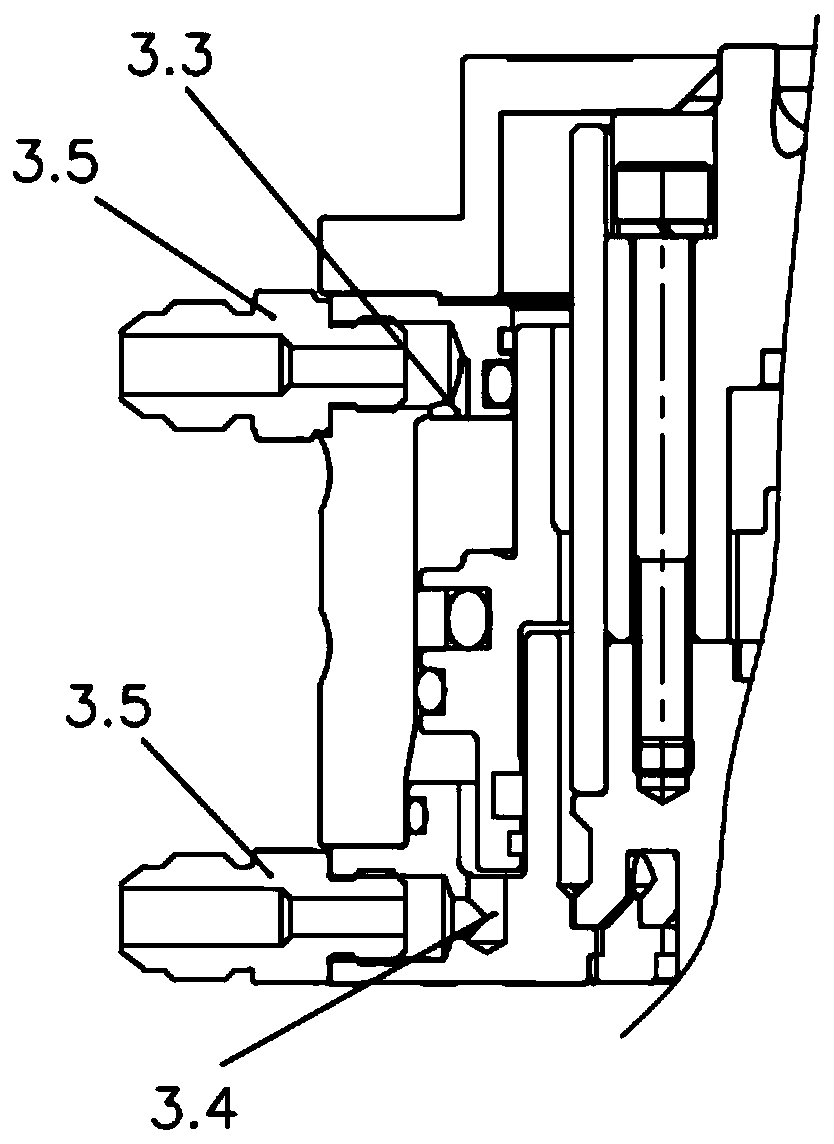

[0025] The cylinder block 3, as a casing, plays a role of protecting and connecting the air source; the cylinder block 3 includes: an upper air inlet 3.3, a lower air inlet 3.4, a first guide belt 3.1 and a first sealing ring 3.2.

[0026] The upper air inlet 3.3 passes through the cylinder block 3, and a joint 3.5 is arranged outside the upper air inlet 3.3.

[0027] The lower air intake hole 3.4 penetrates the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com