Hydrogenation method for producing BTX fraction from catalytic cracking diesel oil

A technology for catalytic cracking of diesel oil and distillates, which can be used in hydrotreating process, hydrocarbon oil treatment products, petroleum industry, etc., and can solve the problems of poor selectivity of BTX

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

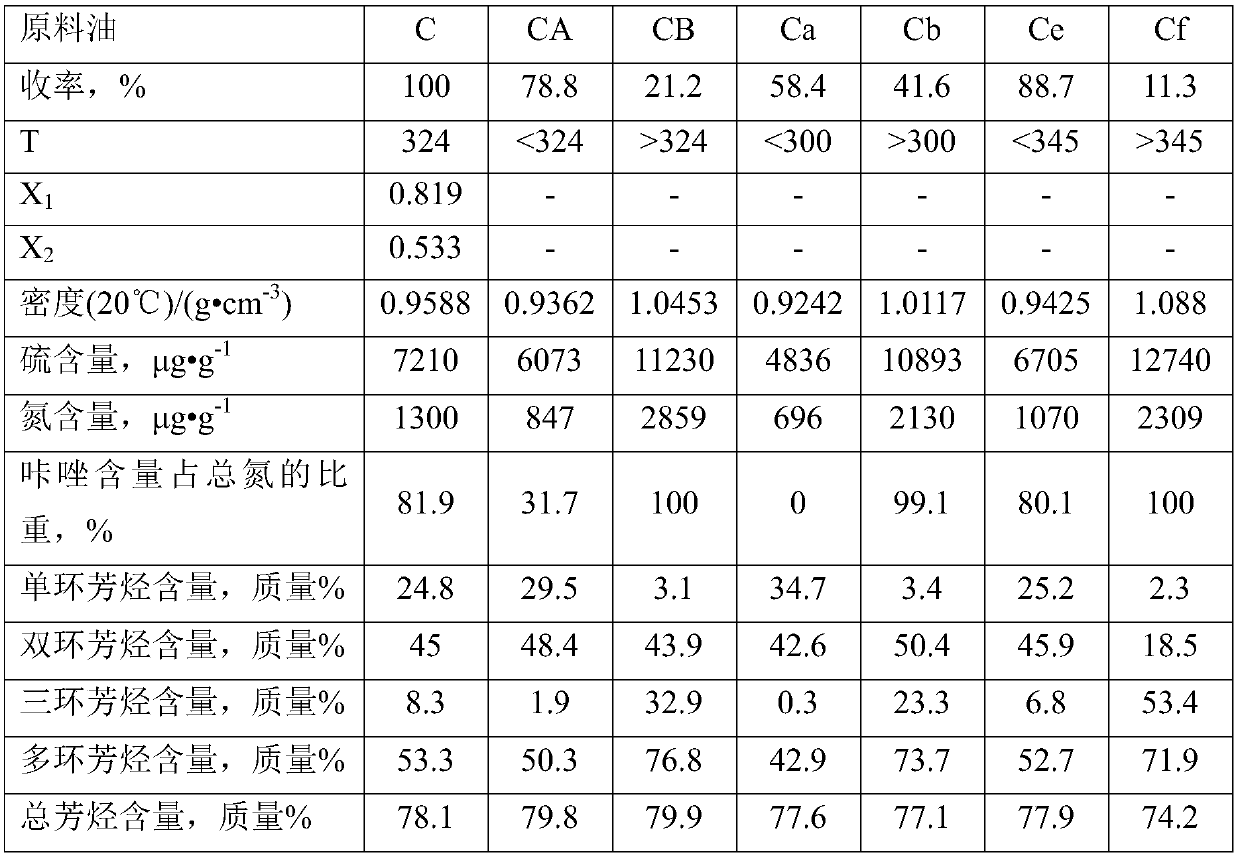

[0053] The feed oil C is cut into light FCC diesel fraction CA (324°C) at the cut point of 324°C. CA enters the low-pressure hydrocracking unit, and contacts and reacts with hydrofinishing catalyst A and hydrocracking catalyst B in turn. In the low-pressure hydrocracking unit, the denitrification and aromatic hydrocarbon saturation depth of the hydrofinishing reaction zone I are controlled, so that the nitrogen content in the liquid-phase reaction effluent of the hydrofinishing reaction zone I is reduced to below 20 μg / g. CB enters the medium-pressure hydrocracking unit, and contacts and reacts with hydrofinishing catalyst A and hydrocracking catalyst B in sequence. The reaction product of the low-pressure hydrocracking unit is fractionated together with the reaction product of the medium-pressure hydrocracking unit to obtain a gaseous, BTX-enriched fraction and a diesel fraction. The reaction conditions are as shown in Table 3, and the product properties are as shown in Tabl...

Embodiment 2

[0057] The feed oil C is cut into light FCC diesel fraction Ca (300°C) at a cut point of 300°C. Ca enters the low-pressure hydrocracking unit, and successively contacts and reacts with hydrofinishing catalyst A and hydrocracking catalyst B. The nitrogen content in the liquid phase reaction effluent from reaction zone I is reduced to below 20 μg / g. Cb enters the medium-pressure hydrocracking unit, and successively contacts and reacts with hydrofinishing catalyst A and hydrocracking catalyst B. The reaction product of the low-pressure hydrocracking unit is fractionated together with the reaction product of the medium-pressure hydrocracking unit to obtain a gaseous, BTX-enriched fraction and a diesel fraction. The reaction conditions are as shown in Table 3, and the product properties are as shown in Table 4.

[0058] It can be seen from Table 4 that when the cutting temperature of feed oil C is lower than the upper limit T of the cutting point, the nitrogen content of the ligh...

Embodiment 3

[0063] The feed oil C is cut into light FCC diesel fraction CA (324°C) at the cut point of 324°C. CA enters the low-pressure hydrocracking unit, and contacts and reacts with hydrofinishing catalyst A and hydrocracking catalyst B in turn. In the low-pressure hydrocracking unit, the denitrification and aromatic hydrocarbon saturation depth of the hydrofinishing reaction zone I are controlled, so that the nitrogen content in the liquid-phase reaction effluent of the hydrofinishing reaction zone I is reduced to below 20 μg / g. CB enters the medium-pressure hydrocracking unit, and contacts and reacts with hydrofinishing catalyst A and hydrocracking catalyst B in sequence. The reaction product of the low-pressure hydrocracking unit is fractionated together with the reaction product of the medium-pressure hydrocracking unit to obtain a gaseous, BTX-enriched fraction and a diesel fraction. Some of the diesel fractions are all recycled to the raw material system. The reaction conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com