A kind of hydrogenation method of catalytic cracking diesel oil production BTX fraction

A technology for catalytic cracking of diesel oil and fractions, which is applied in the fields of hydrocarbon oil treatment products, hydrotreating process, hydrocarbon oil treatment, etc. It can solve the problems of poor selectivity of BTX and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

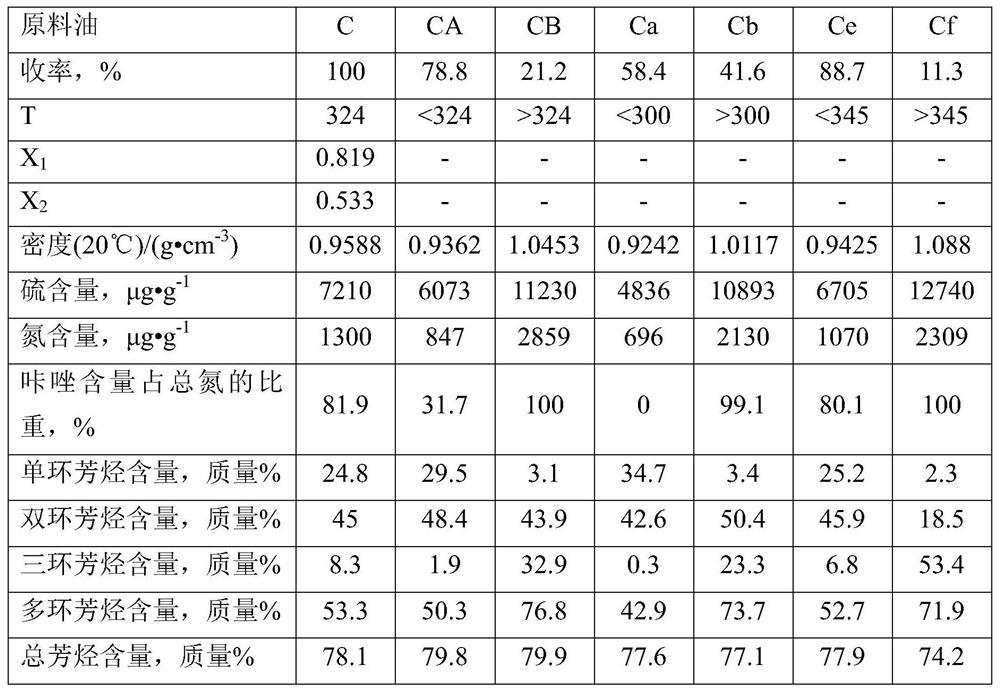

[0053] The raw material oil C was cut into a cleavage of 324 ° C to a light catalytic cracking diesel fraction Ca ( 324 ° C). The CA enters the low pressure hydrocracking unit, sequentially contacts the hydrothermal catalyst A and the hydrocracking catalyst B. In the low pressure hydrocracking unit, the nitrogen-free reaction zone I of hydrotreating reaction zone I is controlled to reduce the nitrogen content of the hydrothermal reaction zone I liquid phase reaction effluent to 20 μg / g below. The Cb enters the medium pressure hydrocracking unit, sequentially contacts the hydrocarbon catalyst A and the hydrocracking catalyst B. The reaction product of the low-pressure hydrocracking unit is distilled with the reaction product of the medium pressure hydrocracking unit to obtain a gas, rich in BTX fraction and diesel fractions. The reaction conditions are shown in Table 3, and the properties of the product are shown in Table 4.

[0054] As can be seen from Table 1, after the catalyt...

Embodiment 2

[0057] The raw oil C was cut into a cleavage of 300 ° C to a light catalytic cracking diesel fraction Ca ( 300 ° C). The CA enters the low pressure hydrocracking unit, sequentially contacts the hydrothermal catalyst A and the hydrocracking catalyst B, and controls the hydrotreating reaction zone I of the hydrotreating reaction zone I and the aramid hydrocarbon saturated depth of hydrocrystallization and the hydrogenation. The nitrogen content decreases to 20 μg / g in the reaction zone I liquid phase reaction effluent. The Cb enters the medium pressure hydrocracking unit, sequentially contacts the hydrocarbon catalyst A and the hydrocracking catalyst B. The reaction product of the low-pressure hydrocracking unit is distilled with the reaction product of the medium pressure hydrocracking unit to obtain a gas, rich in BTX fraction and diesel fractions. The reaction conditions are shown in Table 3, and the properties of the product are shown in Table 4.

[0058] As can be seen from T...

Embodiment 3

[0063] The raw material oil C was cut into a cleavage of 324 ° C to a light catalytic cracking diesel fraction Ca ( 324 ° C). The CA enters the low pressure hydrocracking unit, sequentially contacts the hydrothermal catalyst A and the hydrocracking catalyst B. In the low pressure hydrocracking unit, the nitrogen-free reaction zone I of hydrotreating reaction zone I is controlled to reduce the nitrogen content of the hydrothermal reaction zone I liquid phase reaction effluent to 20 μg / g below. The Cb enters the medium pressure hydrocracking unit, sequentially contacts the hydrocarbon catalyst A and the hydrocracking catalyst B. The reaction product of the low-pressure hydrocracking unit is distilled with the reaction product of the medium pressure hydrocracking unit to obtain a gas, rich in BTX fraction and diesel fractions. The partial diesel fractions are all circulated to the raw material system. The reaction conditions are shown in Table 5, and the properties of the product a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com